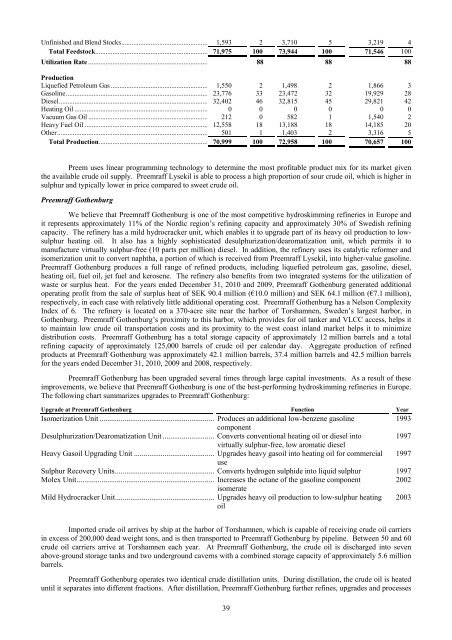

Unfinished and Blend Stocks.................................................. 1,593 2 3,710 5 3,219 4Total Feedstock................................................................. 71,975 100 73,944 100 71,546 100Utilization Rate ..................................................................... 88 88 88ProductionLiquefied Petroleum Gas ........................................................ 1,550 2 1,498 2 1,866 3Gasoline.................................................................................. 23,776 33 23,472 32 19,929 28Diesel...................................................................................... 32,402 46 32,815 45 29,821 42Heating Oil ............................................................................. 0 0 0 0 0 0Vacuum Gas Oil ..................................................................... 212 0 582 1 1,540 2Heavy Fuel Oil ....................................................................... 12,558 18 13,188 18 14,185 20Other....................................................................................... 501 1 1,403 2 3,316 5Total Production............................................................... 70,999 100 72,958 100 70,657 100<strong>Preem</strong> uses linear programming technology to determine the most profitable product mix for its market giventhe available crude oil supply. <strong>Preem</strong>raff Lysekil is able to process a high proportion of sour crude oil, which is higher insulphur and typically lower in price compared to sweet crude oil.<strong>Preem</strong>raff GothenburgWe believe that <strong>Preem</strong>raff Gothenburg is one of the most competitive hydroskimming refineries in Europe andit represents approximately 11% of the Nordic region’s refining capacity and approximately 30% of Swedish refiningcapacity. The refinery has a mild hydrocracker unit, which enables it to upgrade part of its heavy oil production to lowsulphurheating oil. It also has a highly sophisticated desulphurization/dearomatization unit, which permits it tomanufacture virtually sulphur-free (10 parts per million) diesel. In addition, the refinery uses its catalytic reformer andisomerization unit to convert naphtha, a portion of which is received from <strong>Preem</strong>raff Lysekil, into higher-value gasoline.<strong>Preem</strong>raff Gothenburg produces a full range of refined products, including liquefied petroleum gas, gasoline, diesel,heating oil, fuel oil, jet fuel and kerosene. The refinery also benefits from two integrated systems for the utilization ofwaste or surplus heat. For the years ended December 31, 2010 and 2009, <strong>Preem</strong>raff Gothenburg generated additionaloperating profit from the sale of surplus heat of SEK 90.4 million (€10.0 million) and SEK 64.1 million (€7.1 million),respectively, in each case with relatively little additional operating cost. <strong>Preem</strong>raff Gothenburg has a Nelson ComplexityIndex of 6. The refinery is located on a 370-acre site near the harbor of Torshamnen, Sweden’s largest harbor, inGothenburg. <strong>Preem</strong>raff Gothenburg’s proximity to this harbor, which provides for oil tanker and VLCC access, helps itto maintain low crude oil transportation costs and its proximity to the west coast inland market helps it to minimizedistribution costs. <strong>Preem</strong>raff Gothenburg has a total storage capacity of approximately 12 million barrels and a totalrefining capacity of approximately 125,000 barrels of crude oil per calendar day. Aggregate production of refinedproducts at <strong>Preem</strong>raff Gothenburg was approximately 42.1 million barrels, 37.4 million barrels and 42.5 million barrelsfor the years ended December 31, 2010, 2009 and 2008, respectively.<strong>Preem</strong>raff Gothenburg has been upgraded several times through large capital investments. As a result of theseimprovements, we believe that <strong>Preem</strong>raff Gothenburg is one of the best-performing hydroskimming refineries in Europe.The following chart summarizes upgrades to <strong>Preem</strong>raff Gothenburg:Upgrade at <strong>Preem</strong>raff Gothenburg Function YearIsomerization Unit ............................................................ Produces an additional low-benzene gasoline1993componentDesulphurization/Dearomatization Unit ........................... Converts conventional heating oil or diesel into 1997virtually sulphur-free, low aromatic dieselHeavy Gasoil Upgrading Unit .......................................... Upgrades heavy gasoil into heating oil for commercial 1997useSulphur Recovery Units.................................................... Converts hydrogen sulphide into liquid sulphur 1997Molex Unit........................................................................ Increases the octane of the gasoline component 2002isomerateMild Hydrocracker Unit.................................................... Upgrades heavy oil production to low-sulphur heating 2003oilImported crude oil arrives by ship at the harbor of Torshamnen, which is capable of receiving crude oil carriersin excess of 200,000 dead weight tons, and is then transported to <strong>Preem</strong>raff Gothenburg by pipeline. Between 50 and 60crude oil carriers arrive at Torshamnen each year. At <strong>Preem</strong>raff Gothenburg, the crude oil is discharged into sevenabove-ground storage tanks and two underground caverns with a combined storage capacity of approximately 5.6 millionbarrels.<strong>Preem</strong>raff Gothenburg operates two identical crude distillation units. During distillation, the crude oil is heateduntil it separates into different fractions. After distillation, <strong>Preem</strong>raff Gothenburg further refines, upgrades and processes39

the fractions as follows:Liquefied Petroleum Gas Unit. In the liquefied petroleum gas unit, installed in 1967, <strong>Preem</strong>raff Gothenburgseparates the gas fractions (butane and propane) by distillation from the high-octane component.Isomerization Unit. The naphtha fraction (after desulphurization) is processed in a reformer unit to increaseoctane. In <strong>Preem</strong>raff Gothenburg’s isomerization unit, completed in 1993, an additional, low-benzenecomponent for blending gasoline is produced.Desulphurization/Dearomatization Unit. <strong>Preem</strong>raff Gothenburg’s highly sophisticated heating oil/dieseldesulphurization/dearomatization unit was completed in 1997. This unit enables <strong>Preem</strong>raff Gothenburg toproduce virtually sulphur-free (10 parts per million) and low-aromatic diesel from crude oil with highsulphur, which is typically lower in price than crude oil with low-sulphur content.Heavy Gasoil Upgrading Unit. In 1997, <strong>Preem</strong>raff Gothenburg installed a heavy gasoil-upgrading unit,which upgrades heavy gasoil into heating oil for commercial use.Sulphur Recovery Units. The hydrogen sulphide formed during the various desulphurization reactions isfed to <strong>Preem</strong>raff Gothenburg’s sulphur recovery units, which were installed in 1997, and converted to liquidsulphur for resale as a feedstock to chemical companies.Molex Unit. In 2002, <strong>Preem</strong>raff Gothenburg installed a molex unit, which increases the octane of thegasoline component isomerate.Mild Hydrocracker Unit.In 2003, <strong>Preem</strong>raff Gothenburg completed construction of a mild hydrocracker unit, which enables<strong>Preem</strong>raff Gothenburg to upgrade part of its heavy oil production to low-sulphur heating oil.During the first quarter of 2010, we shut down our mild hydrocracker at <strong>Preem</strong>raff Gothenburg for twomonths (until May 2010) in order to modify the unit to partly process renewable feedstock, whichenables us to produce biofuel diesel.After processing, refined products are stored in the facility’s 70 storage tanks and three underground cavernswith a total capacity of approximately 6.5 million barrels. The products are pumped by pipeline from the refinery to anoil terminal in the harbor of Skarvik, two kilometers south of <strong>Preem</strong>raff Gothenburg. From there, we distribute theproduct to the market by ship, rail and truck.<strong>Preem</strong>raff Gothenburg has two integrated systems for the utilization of waste or surplus heat with a totalcapacity in excess of 100 megawatts. These systems enable us to sell surplus heat, which would otherwise be wasted,corresponding to approximately 200,000 barrels of fuel oil per year to the district heating system of the city ofGothenburg and approximately 100,000 barrels of fuel oil per year to <strong>AB</strong> Volvo. <strong>Preem</strong>raff Gothenburg generatedadditional operating profit from these activities of SEK 64.1 million (€7.1 million) in 2009 and SEK 90.4 million(€10.0 million) in 2010 with relatively little additional operating cost.Every four years, <strong>Preem</strong>raff Gothenburg is completely shut down for turnaround maintenance, which includesinspection of all processing units. The maintenance period typically lasts four to six weeks. The most recent majorturnaround maintenance was in the second quarter of 2007 and the next major turnaround maintenance is scheduled forthe third quarter of 2011.The following table shows <strong>Preem</strong>raff Gothenburg’s feedstocks and production for the periods indicated below,along with the relevant percentage of total feedstock and production.Thousandbbls %40For the year ended December 31,2008 2009 2010Thousandbbls %Thousandbbls %FeedstocksSweet Crude Oil...................................................................... 40,573 92 35,238 91 40,650 93Sour Crude Oil........................................................................ — — — — 167 —Unfinished and Blend Stocks.................................................. 3,447 8 3,688 9 3,029 7Total Feedstock................................................................. 44,020 100 38,926 100 43,846 100Utilization Rate ..................................................................... 89 77 86ProductionLiquefied Petroleum Gas ........................................................ 1,029 2 742 2 913 2Gasoline.................................................................................. 11,195 27 10,446 28 11,406 27Diesel...................................................................................... 12,857 30 10,104 27 11,883 28

- Page 2: TABLE OF CONTENTSDisclosure Regardi

- Page 5: which was merged into Preem on Octo

- Page 8 and 9: RISK FACTORSThe risk factors below

- Page 10 and 11: the cost of exploring for, developi

- Page 12 and 13: purchase a minimum of 10% to 20% of

- Page 14 and 15: market price at the time of settlem

- Page 16 and 17: Notes, we would try to obtain waive

- Page 18 and 19: are reasonable grounds for believin

- Page 20 and 21: civil liability, whether or not pre

- Page 22 and 23: SELECTED CONSOLIDATED FINANCIAL DAT

- Page 24 and 25: MANAGEMENT’S DISCUSSION AND ANALY

- Page 26 and 27: Year ended December 31,%2008 2009 C

- Page 28 and 29: arrel in February, increased to app

- Page 30 and 31: (1) Includes sales by our supply an

- Page 32 and 33: SEK 5,519 million, from a loss of S

- Page 34 and 35: Cash flow used in investment activi

- Page 36 and 37: Restrictions on transfers of fundsW

- Page 38 and 39: Variable rate debt—amount due .

- Page 40 and 41: As of December 31, 2008, SEK 21,999

- Page 42 and 43: Our StrengthsOur competitive streng

- Page 44 and 45: Lysekil has a total storage capacit

- Page 48 and 49: Heating Oil .......................

- Page 50 and 51: Business-to-Business DivisionWe pre

- Page 52 and 53: “.nu,” “.org,” “.biz,”

- Page 54 and 55: Energy AB, Huda Trading AB, the Swe

- Page 56 and 57: was incorporated on March 22, 2007,

- Page 58 and 59: RELATED PARTY TRANSACTIONSCapital T

- Page 60 and 61: DESCRIPTION OF CERTAIN INDEBTEDNESS

- Page 62 and 63: effected by the Third Supplemental

- Page 64 and 65: first ranking mortgage certificates

- Page 66 and 67: LEGAL INFORMATIONCorral Petroleum H

- Page 68 and 69: CORRAL PETROLEUM HOLDINGS AB (publ)

- Page 70 and 71: CORRAL PETROLEUM HOLDINGS AB (publ)

- Page 72 and 73: CORRAL PETROLEUM HOLDINGS AB (publ)

- Page 74 and 75: CORRAL PETROLEUM HOLDINGS AB (publ)

- Page 76 and 77: SubsidiariesSubsidiaries are compan

- Page 78 and 79: The refinery installations consist

- Page 80 and 81: of occupational pension insurance,

- Page 82 and 83: Emission rights 2010LysekilGothenbu

- Page 84 and 85: NOTE 2. FINANCIAL RISK MANAGEMENTTh

- Page 86 and 87: In addition to price risk managemen

- Page 88 and 89: The fair value of borrowing is calc

- Page 90 and 91: Reconciliation with the Group’s t

- Page 92 and 93: The Board members including the Cha

- Page 94 and 95: NOTE 12. EXPENSES BROKEN DOWN BY TY

- Page 96 and 97:

NOTE 16. EXCHANGE RATE DIFFERENCES

- Page 98 and 99:

Equipment, tools, fixtures and fitt

- Page 100 and 101:

NOTE 23. TRADE AND OTHER RECEIVABLE

- Page 102 and 103:

The change in the fair value of pla

- Page 104 and 105:

Loan conditions, effective interest

- Page 106 and 107:

Capitalized interest cost..........

- Page 108:

SalesDecember 31, 2009AccountsPurch