BUFFING COMPOUND

BUFFING COMPOUND

BUFFING COMPOUND

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

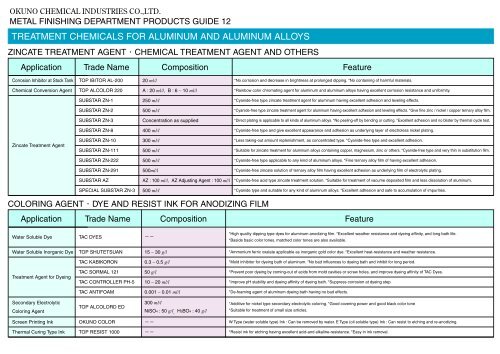

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 12TREATMENT CHEMICALS FOR ALUMINUM AND ALUMINUM ALLOYSZINCATE TREATMENT AGENTCHEMICAL TREATMENT AGENT AND OTHERSApplication Trade Name Composition FeatureCorrosion Inhibitor at Stock TankTOP IBITOR AL-20020 ml/l*No corrosion and decrease in brightness at prolonged dipping. *No containing of harmful materials.Chemical Conversion AgentTOP ALCOLOR 220A : 20 ml/l, B : 6 ~ 10 ml/l*Rainbow color chromating agent for aluminum and aluminum alloys having excellent corrosion resistance and uniformity.SUBSTAR ZN-1250 ml/l*Cyanide-free type zincate treatment agent for aluminum having excellent adhesion and leveling effects.SUBSTAR ZN-2500 ml/l*Cyanide-free type zincate treatment agent for aluminum having excellent adhesion and leveling effects. *Give fine zinc / nickel / copper ternary alloy film.SUBSTAR ZN-3Concentration as supplied*Direct plating is applicable to all kinds of aluminum alloys. *No peeling-off by bending or cutting. *Excellent adhesion and no blister by thermal cycle test.SUBSTAR ZN-8400 ml/l*Cyanide-free type and give excellent appearance and adhesion as underlying layer of electroless nickel plating.Zincate Treatment AgentSUBSTAR ZN-10SUBSTAR ZN-111300 ml/l500 ml/l*Less taking-out amount replenishment, as concentrated type. *Cyanide-free type and excellent adhesion.*Suitable for zincate treatment for aluminum alloys containing copper, magnesium, zinc or others. *Cyanide-free type and very thin in substitution film.SUBSTAR ZN-222500 ml/l*Cyanide-free type applicable to any kind of aluminum alloys. *Fine ternary alloy film of having excellent adhesion.SUBSTAR ZN-291500ml/l*Cyanide-free zincate solution of ternary alloy film having excellent adhesion as underlying film of electrolytic plating.SUBSTAR AZAZ : 100 ml/l, AZ Adjusting Agent : 100 ml/l*Cyanide-free acid type zincate treatment solution. *Suitable for treatment of vacume deposited film and less dissolution of aluminum.SPECIAL SUBSTAR ZN-3500 ml/l*Cyanide type and suitable for any kind of aluminum alloys. *Excellent adhesion and safe to accumulation of impurities.COLORING AGENTDYE AND RESIST INK FOR ANODIZING FILMApplication Trade Name Composition FeatureWater Soluble DyeTAC DYES*High quality dipping type dyes for aluminum anodizing film. *Excellent weather resistance and dyeing affinity, and long bath life.*Baside basic color tones. matched color tones are also available.Water Soluble Inorganic DyeTOP SHUTETSUAN15 ~ 30 g/l*Ammonium ferric oxalate applicable as inorganic gold color dye. *Excellent heat-resistance and weather resistance.TAC KABIKORON0.3 ~ 0.5 g/l*Mold inhibitor for dyeing bath of aluminum. *No bad influences to dyeing bath and inhibit for long period.Treatment Agent for DyeingTAC SORMAL 121TAC CONTROLLER PH-550 g/l10 ~ 20 ml/l*Prevent poor dyeing by coming-out of acids from mold cavities or screw holes, and improve dyeing affinity of TAC Dyes.*Improve pH stability and dyeing affinity of dyeing bath. *Suppress corrosion at dyeing step.TAC ANTIFOAM0.001 ~ 0.01 ml/l*De-foaming agent of aluminum dyeing bath having no bad effects.Secondary ElectrolyticColoring AgentTOP ALCOLORD ED300 ml/lNiSO4 : 50 g/l , H3BO4 : 40 g/l*Additive for nickel type secondary electrolytic coloring. *Good covering power and good black color tone*Suitable for treatment of small size articles.Screen Printing InkOKUNO COLORW Type (water soluble type) Ink : Can be removed by water. E Type (oil soluble type) Ink : Can resist to etching and re-anodizing.Thermal Curing Type InkTOP RESIST 1000*Resist ink for etching having excellent acid-and alkaline-resistance. *Easy in ink removal.