BUFFING COMPOUND

BUFFING COMPOUND

BUFFING COMPOUND

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

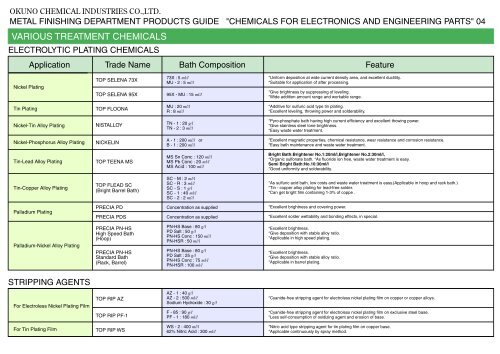

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR ELECTRONICS AND ENGINEERING PARTS" 04VARIOUS TREATMENT CHEMICALSELECTROLYTIC PLATING CHEMICALSApplication Trade Name Bath Composition FeatureNickel PlatingTOP SELENA 73XTOP SELENA 95X73X : 5 ml/lMU - 2 : 5 ml/l95X - MU : 15 ml/l*Uniform deposition at wide current density area, and excellent ductility.*Suitable for application of after processing.*Give brightness by suppressing of leveling.*Wide addition amount range and workable range.Tin PlatingTOP FLOONAMU : 20 ml/lR : 8 ml/l*Additive for sulfuric acid type tin plating.*Excellent leveling, throwing power and solderability.Nickel-Tin Alloy PlatingNISTALLOYTN - 1 : 20 g/lTN - 2 : 3 ml/l*Pyro-phosphate bath having high current efficiency and excellent thowing power.*Give stainless steel tone brightness.*Easy waste water treatment.Nickel-Phosphorus Alloy PlatingNICKELINA - 1 : 200 ml/l orB - 1 : 200 ml/l*Excellent magnetic properties, chemical resistance, wear resistance and corrosion resistance.*Easy bath maintenance and waste water treatment.Tin-Lead Alloy PlatingTOP TEENA MSMS Sn : 120 ml/lMS Pb : 20 ml/lMS : 100 ml/lBright Bath:Brightener No.1:20ml/l,Brightener No.2:30ml/l,*Organic sulfonate bath. *As fluoride ion free, waste water treatment is easy.Semi Bright Bath:No.10:30ml/l*Good uniformity and solderability.Tin-Copper Alloy PlatingTOP FLEAD SC(Bright Barrel Bath)SC - M : 2 ml/lSC - R : 3 ml/lSC - S : 1 g/lSC - 1 : 40 ml/lSC - 2 : 2 ml/l*As sulfuric acid bath, low costs and waste water treatment is easy.(Applicable in hoop and rack bath.)*Tin - copper alloy plating for lead-free solder.*Can get bright film containing 1-3% of coppe .Palladium PlatingPRECIA PDPRECIA PDSConcentration as suppliedConcentration as supplied*Excellent brightness and covering power.*Excellent solder wettability and bonding effects, in special.Palladium-Nickel Alloy PlatingPRECIA PN-HSHigh Speed Bath(Hoop)PRECIA PN-HSStandard Bath(Rack, Barrel)PN-HS Base : 80 g/lPD Salt : 50 g/lPN-HS Conc : 150 ml/lPN-HSR : 50 ml/lPN-HS Base : 80 g/lPD Salt : 25 g/lPN-HS Conc : 75 ml/lPN-HSR : 100 ml/l*Excellent brightness.*Give deposition with stable alloy ratio.*Applicable in high speed plating.*Excellent brightness.*Give deposition with stable alloy ratio.*Applicable in barrel plating.STRIPPING AGENTSFor Electroless Nickel Plating FilmTOP RIP AZTOP RIP PF-1AZ - 1 : 40 g/lAZ - 2 : 500 ml/lSodium Hydroxide : 30 g/lF - 85 : 90 g/lPF - 1 : 180 ml/l*Cyanide-free stripping agent for electroless nickel plating film on copper or copper alloys.*Cyanide-free stripping agent for electroless nickel plating film on exclusive steel base.*Less self-consumption of oxidizing agent and erosion of base.For Tin Plating FilmTOP RIP WSWS - 2 : 400 ml/l62% Nitric Acid : 300 ml/l*Nitric acid type stripping agent for tin plating film on copper base.*Applicable continuously by spray method.