BUFFING COMPOUND

BUFFING COMPOUND

BUFFING COMPOUND

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

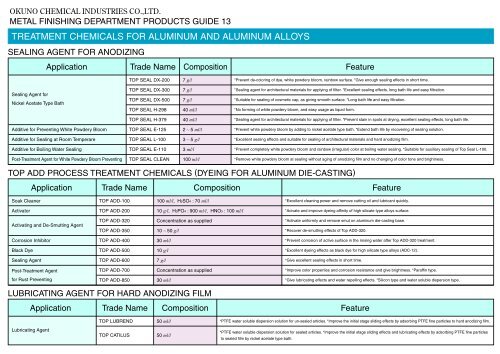

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 13TREATMENT CHEMICALS FOR ALUMINUM AND ALUMINUM ALLOYSSEALING AGENT FOR ANODIZINGApplication Trade Name Composition FeatureTOP SEAL DX-2007 g/l*Prevent de-coloring of dye, white powdery bloom, rainbow surface. *Give enough sealing effects in short time.Sealing Agent forNickel Acetate Type BathTOP SEAL DX-300TOP SEAL DX-500TOP SEAL H-2987 g/l7 g/l40 ml/l*Sealing agent for architectural materials for applying of filter. *Excellent sealing effects, long bath life and easy filtration.*Suitable for sealing of cosmetic cap, as giving smooth surface. *Long bath life and easy filtration.*No forming of white powdery bloom, and easy usage as liquid form.TOP SEAL H-37940 ml/l*Sealing agent for architectural materials for applying of filter. *Prevent stain in spots at drying, excellent sealing effects, long bath life.Additive for Preventing White Powdery BloomTOP SEAL E-1252 ~ 5 ml/l*Prevent white powdery bloom by adding to nickel acetate type bath. *Extend bath life by recovering of sealing solution.Additive for Sealing at Room TemperareTOP SEAL L-1003 ~ 5 g/l*Excellent sealing effects and suitable for sealing of architectural materials and hard anodizing film.Additive for Boiling Water SealingTOP SEAL E-1103 ml/l*Prevent completely white powdery bloom and rainbow (irregular) color at boiling water sealing. *Suitable for auxiliary sealing of Top Seal L-100.Post-Treatment Agent for White Powdery Bloom PreventingTOP SEAL CLEAN100 ml/l*Remove white powdery bloom at sealing without aging of anodizing film and no changing of color tone and brightness.TOP ADD PROCESS TREATMENT CHEMICALS (DYEING FOR ALUMINUM DIE-CASTING)Application Trade Name Composition FeatureSoak CleanerTOP ADD-100100 ml/l, H2SO4 : 70 ml/l*Excellent cleaning power and remove cutting oil and lubricant quickly.ActivatorTOP ADD-20010 g/l, H3PO4 : 900 ml/l, HNO3 : 100 ml/l*Acivate and improve dyeing affinity of high silicate type alloys surface.Activating and De-Smutting AgentTOP ADD-320TOP ADD-350Concentration as supplied10 ~ 50 g/l*Activate uniformly and remove smut on aluminum die-casting base.*Recover de-smutting effects of Top ADD-320.Corrosion InhibitorTOP ADD-40030 ml/l*Prevent corrosion of active surface in the rinsing water after Top ADD-320 treatment.Black DyeTOP ADD-50010 g/l*Excellent dyeing effects as black dye for high silicate type alloys (ADC-12).Sealing AgentTOP ADD-6007 g/l*Give excellent sealing effects in short time.Post-Treatment AgentTOP ADD-700Concentration as supplied*Improve color properties and corrosion resistance and give brightness. *Paraffin type.for Rust PreventingTOP ADD-85030 ml/l*Give lubricating effects and water repelling effects. *Silicon type and water soluble dispersion type.LUBRICATING AGENT FOR HARD ANODIZING FILMApplication Trade Name Composition FeatureTOP LUBREND50 ml/l*PTFE water soluble dispersion solution for un-sealed articles. *Improve the initial stage sliding effects by adsorbing PTFE fine particles to hard anodizing film.Lubricating AgentTOP CATILUS50 ml/l*PTFE water soluble dispersion solution for sealed articles. *Improve the initial stage sliding effects and lubricating effects by adsorbing PTFE fine particlesto sealed film by nickel acetate type bath.