BUFFING COMPOUND

BUFFING COMPOUND

BUFFING COMPOUND

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

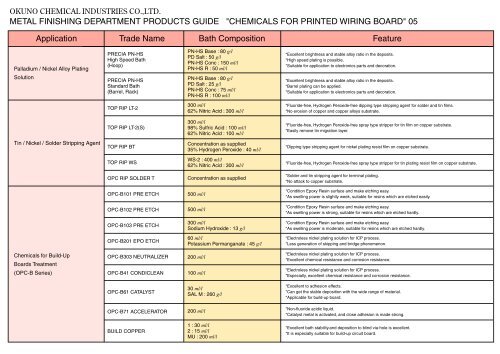

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR PRINTED WIRING BOARD" 05Application Trade Name Bath Composition FeaturePalladium / Nickel Alloy PlatingSolutionPRECIA PN-HSHigh Speed Bath(Hoop)PRECIA PN-HSStandard Bath(Barrel, Rack)PN-HS Base : 80 g/lPD Salt : 50 g/lPN-HS Conc : 150 ml/lPN-HS R : 50 ml/lPN-HS Base : 80 g/lPD Salt : 25 g/lPN-HS Conc : 75 ml/lPN-HS R : 100 ml/l*Excellent brightness and stable alloy ratio in the deposits.*High speed plating is possible.*Suitable for application to electronics parts and decoration.*Excellent brightness and stable alloy ratio in the deposits.*Barrel plating can be applied.*Suitable for application to electronics parts and decoration.TOP RIP LT-2300 ml/l62% Nitric Acid : 300 ml/l*Fluoride-free, Hydrogen Peroxide-free dipping type stripping agent for solder and tin films.*No erosion of copper and copper alloys substrate.TOP RIP LT-2(S)300 ml/l98% Sulfric Acid : 100 ml/l62% Nitric Acid : 100 ml/l*Fluoride-free, Hydrogen Peroxide-free spray type stripper for tin film on copper substrate.*Easily remove tin migration layer.Tin / Nickel / Solder Stripping AgentTOP RIP BTConcentration as supplied35% Hydrogen Peroxide : 40 ml/l*Dipping type stripping agent for nickel plating resist film on copper substrate.TOP RIP WSWS-2 : 400 ml/l62% Nitric Acid : 300 ml/l*Fluoride-free, Hydrogen Peroxide-free spray type stripper for tin plating resist film on copper substrate.OPC RIP SOLDER TConcentration as supplied*Solder and tin stripping agent for terminal plating.*No attack to copper substrate.OPC-B101 PRE ETCH500 ml/l*Condition Epoxy Resin surface and make etching easy.*As swelling power is slightly week, suitable for resins which are etched easily.OPC-B102 PRE ETCH500 ml/l*Condition Epoxy Resin surface and make etching easy.*As swelling power is strong, suitable for resins which are etched hardly.OPC-B103 PRE ETCH300 ml/lSodium Hydroxide : 13 g/l*Condition Epoxy Resin surface and make etching easy.*As swelling power is moderate, suitable for resins which are etched hardly.OPC-B201 EPO ETCH60 ml/lPotassium Permanganate : 45 g/l*Electroless nickel plating solution for ICP process.*Less generation of skipping and bridge phenomenon.Chemicals for Build-UpBoards Treatment(OPC-B Series)OPC-B303 NEUTRALIZEROPC-B41 CONDICLEAN200 ml/l100 ml/l*Electroless nickel plating solution for ICP process.*Excellent chemical resistance and corrosion resistance.*Electroless nickel plating solution for ICP process.*Especially, excellent chemical resistance and corrosion resistance.OPC-B61 CATALYST30 ml/lSAL M : 260 g/l*Excellent to adhesion effects.*Can get the stable deposition with the wide range of material.*Applicable for build-up board.OPC-B71 ACCELERATOR200 ml/l*Non-fluoride acidic liquid.*Catalyst metal is activated, and close adhesion is made strong.BUILD COPPER1 : 30 ml/l2 : 15 ml/lMU : 200 ml/l*Excellent bath stability.and deposition to blind via-hole is excellent.*It is especially suitable for build-up circuit board.