BUFFING COMPOUND

BUFFING COMPOUND

BUFFING COMPOUND

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

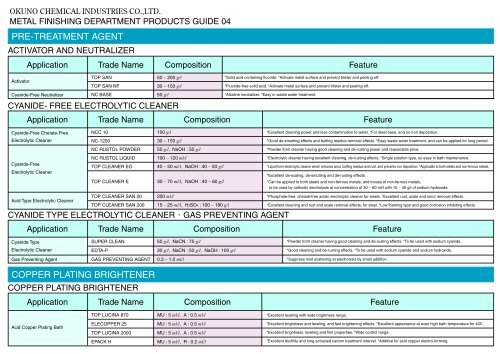

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 04PRE-TREATMENT AGENTACTIVATOR AND NEUTRALIZERApplication Trade Name Composition FeatureActivatorTOP SANTOP SAN NF50 ~ 200 g/l30 ~ 150 g/l*Solid acid containing fluoride. *Activate metal surface and prevent blister and peeling-off.*Fluoride-free solid acid. *Activate metal surface and prevent blister and peeling-off.Cyanide-Free NeutralizerNC BASE50 g/lCYANIDE- FREE ELECTROLYTIC CLEANER*Alkaline neutralizer. *Easy in waste water treatment.Application Trade Name Composition FeatureCyanide-Free Chelate-FreeNCC 10100 g/l*Excellent cleaning power and less contamination to water. *For steel base, and no iron deposition.Electrolytic CleanerNC-120030 ~ 150 g/l*Good de-smutting effects and buffing residue removal effects. *Easy waste water treatment, and can be applied for long period.NC RUSTOL POWDER50 g/l, NaOH : 50 g/l*Powder form cleaner having good cleaning and de-rusting power and reasonable price.Cyanide-FreeElectrolytic CleanerNC RUSTOL LIQUIDTOP CLEANER EOTOP CLEANER E100 ~ 120 ml/l40 ~ 50 ml/l, NaOH : 40 ~ 50 g/l30 ~ 70 ml/l, NaOH : 40 ~ 60 g/l*Electrolytic cleaner having excellent cleaning, de-rusting effects. *Single solution type, so easy in bath maintenance.*Liquid form electrolytic cleaner which removes smut, buffing residue and rust, and prevents iron deposition. *Applicable to both steels and non-ferrous metals.*Excellent de-scaling, de-smutting and de-rusting effects.*Can be applied to both steels and non-ferrous metals, and incase of non-ferrous metals,to be used by cathodic electrolysis at concentration of 30 ~ 60 ml/l with 10 ~ 40 g/l of sodium hydroxide.TOP CLEANER SAN 20 200 ml/l*Phosphate-free, chelate-free acidic electrolytic cleaner for steels. *Excellent rust, scale and smut removal effects.Acid Type Electrolytic CleanerTOP CLEANER SAN 200 15 ~ 25 ml/l, H2SO4 : 100 ~ 180 g/l*Excellent cleaning and rust and scale removal effects, for steel. *Low foaming type and good corrosion inhibiting effects.CYANIDE TYPE ELECTROLYTIC CLEANERGAS PREVENTING AGENTApplication Trade Name Composition FeatureCyanide TypeSUPER CLEAN50 g/l, NaCN : 75 g/l*Powder form cleaner having good cleaning and de-rusting effects. *To be used with sodium cyanide.Electrolytic CleanerEDTA-P30 g/l, NaCN : 50 g/l, NaOH : 100 g/l*Good cleaning and de-rusting effects. *To be used with sodium cyanide and sodium hydroxide.Gas Preventing AgentGAS PREVENTING AGENT0.3 ~ 1.0 ml/l*Suppress mist scattering at electrolysis by small addition.COPPER PLATING BRIGHTENERCOPPER PLATING BRIGHTENERApplication Trade Name Composition FeatureTOP LUCINA 870MU : 5 ml/l, A : 0.5 ml/l*Excellent leveling with wide brightness range.Acid Copper Plating BathELECOPPER 25TOP LUCINA 2000MU : 5 ml/l, A : 0.5 ml/lMU : 5 ml/l, A : 0.5 ml/l*Excellent brightness and leveling, and fast brightening effects. *Excellent appearance at even high bath temperature for 40C.*Excellent brightness, leveling and film properties. *Wide control range.EPACK HMU : 5 ml/l, R : 0.2 ml/l*Excellent ductility and long activated carbon treatment interval. *Additive for acid copper electro-forming.