BUFFING COMPOUND

BUFFING COMPOUND

BUFFING COMPOUND

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

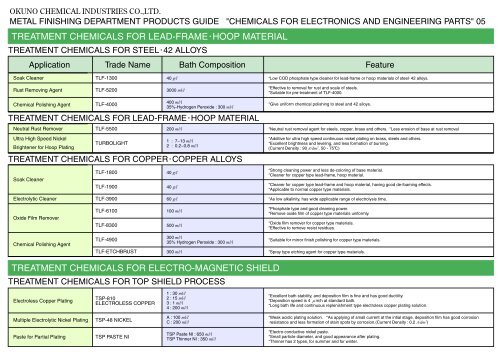

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR ELECTRONICS AND ENGINEERING PARTS" 05TREATMENT CHEMICALS FOR LEAD-FRAMEHOOP MATERIALTREATMENT CHEMICALS FOR STEEL42 ALLOYSApplication Trade Name Bath Composition FeatureSoak CleanerTLF-130040 g/l*Low COD phosphate type cleaner for lead-frame or hoop materials of steel42 alloys.Rust Removing AgentTLF-52003000 ml/l*Effective to removal for rust and scale of steels.*Suitable for pre-treatment of TLF-4000.Chemical Polishing AgentTLF-4000400 ml/l35%-Hydrogen Peroxide : 300 ml/lTREATMENT CHEMICALS FOR LEAD-FRAMEHOOP MATERIALNeutral Rust RemoverUltra High Speed NickelBrightener for Hoop PlatingTLF-5500TURBOLIGHT200 ml/l1 : 7~13 ml/l2 : 0.2~0.8 ml/lTREATMENT CHEMICALS FOR COPPERCOPPER ALLOYSSoak CleanerElectrolytic CleanerTLF-1800TLF-1900TLF-390040 g/l40 g/l60 g/l*Give uniform chemical polishing to steel and 42 alloys.*Neutral rust removal agent for steels, copper, brass and others. *Less erosion of base at rust removal*Additive for ultra high speed continuous nickel plating on brass, steels and others.*Excellent brightness and leveling, and less formation of burning.(Current Density : 90 A/dm 2 , 50 - 75)*Strong cleaning power and less de-coloring of base material.*Cleaner for copper type lead-frame, hoop material.*Cleaner for copper type lead-frame and hoop material, having good de-foaming effects.*Applicable to normal copper type materials.*As low alkalinity, has wide applicable range of electrolysis time.Oxide Film RemoverTLF-6100TLF-8300100 ml/l500 ml/l*Phosphate type and good cleaning power.*Remove oxide film of copper type materials uniformly.*Oxide film remover for copper type materials.*Effective to remove resist residues.Chemical Polishing AgentTLF-4900TLF-ETCHBRUST300 ml/l35% Hydrogen Peroxide : 300 ml/l300 ml/l*Suitable for mirror finish polishing for copper type materials.*Spray type etching agent for copper type materials.TREATMENT CHEMICALS FOR ELECTRO-MAGNETIC SHIELDTREATMENT CHEMICALS FOR TOP SHIELD PROCESSElectroless Copper PlatingTSP-810ELECTROLESS COPPER1 : 30 ml/l2 : 15 ml/l3 : 1 ml/l4 : 200 ml/l*Excellent bath stability, and deposition film is fine and has good ductility.*Deposition speed is 4 m/h at standard bath.*Long bath life and continuous replenishment type electroless copper plating solution.Multiple Electrolytic Nickel PlatingTSP-48 NICKELA : 100 ml/lC : 200 ml/l*Weak acidic plating solution. *As applying of small current at the intial stage, deposition film has good corrosionresistance and less formation of stain spots by corrosion.(Current Density : 0.2 A/dm 2 )Paste for Partial PlatingTSP PASTE NITSP Paste NI : 650 ml/lTSP Thinner NI : 350 ml/l*Electro-conductive nickel paste.*Small particle diameter, and good appearance after plating.*Thinner has 2 types, for summer and for winter.