BUFFING COMPOUND

BUFFING COMPOUND

BUFFING COMPOUND

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

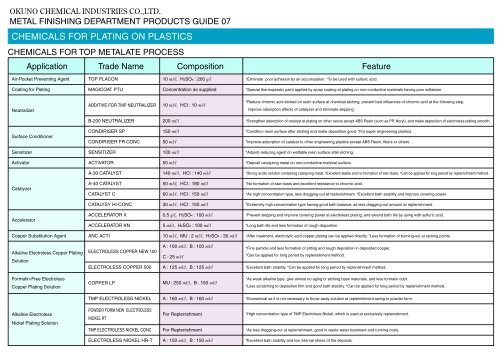

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 07CHEMICALS FOR PLATING ON PLASTICSCHEMICALS FOR TOP METALATE PROCESSApplication Trade Name Composition FeatureAir-Pocket Preventing AgentTOP PLACON10 ml/l, H2SO4 : 200 g/l*Eliminate poor adhesion by air accumulation. *To be used with sulfuric acid.Coating for PlatingMAGICOAT PTUConcentration as supplied*Special thermoplastic paint applied by spray coating at plating on non-conductive materials having poor adhesion.NeutralizerADDITIVE FOR TMP NEUTRALIZER10 ml/l, HCl : 10 ml/l*Reduce chromic acid sticked on resin surface at chemical etching, prevent bad influences of chromic acid at the following step,improve adsorption effects of catalyzer and eliminate skipping.B-200 NEUTRALIZER200 ml/l*Strengthen adsorption of catalyst at plating on other resins except ABS Resin (such as PP, Noryl), and make deposition of electroless plating smooth.Surface ConditionerCONDIRISER SPCONDIRISER FR CONC150 ml/l50 ml/l*Condition resin surface after etching and make deposition good. *For super engineering plastics.*Improve adsorption of catalyst to other engineering plastics except ABS Resin, fibers or others.SensitizerSENSITIZER100 ml/l*Adsorb reducing agent on wettable resin surface after etching.ActivatorACTIVATOR50 ml/l*Deposit catalyzing metal on non-conductive material surface.A-30 CATALYST140 ml/l, HCl : 140 ml/l*Strong acidic solution containing catalyzing metal. *Excellent stable and no formation of star-dusts. *Can be applied for long period by replenishment method.CatalyzerA-40 CATALYSTCATALYST C50 ml/l, HCl : 180 ml/l60 ml/l, HCl : 150 ml/l*No formation of star-dusts and excellent resistance to chromic acid.*As high concentration type, less dragging-out at replenishment. *Excellent bath stability and improve covering power.CATALYSY HI-CONC30 ml/l, HCl : 150 ml/l*Extremely high concentration type having good bath balance, as less dragging-out amount at replenishment.AcceleratorACCELERATOR XACCELERATOR KN0.5 g/l, H2SO4 : 100 ml/l5 ml/l, H2SO4 : 100 ml/l*Prevent skipping and improve covering power at electroless plating, and extend bath life by using with sulfuric acid.*Long bath life and less formation of rough deposition.Copper Substitution AgentANC ACTI10 ml/l, MU : 2 ml/l, H2SO4 : 30 ml/l*After treatment, electrolytic acid copper plating can be applied directly. *Less formation of burning-out at racking points.Alkaline Electroless Copper PlatingSolutionELECTROLESS COPPER NEW 100ELECTROLESS COPPER 500A : 100 ml/l, B : 100 ml/lC : 25 ml/lA : 125 ml/l, B : 125 ml/l*Fine particle and less formation of pitting and rough deposition in deposited copper.*Can be applied for long period by replenishment method.*Excellent bath stability. *Can be applied for long period by replenishment method.Formalin-Free ElectrolessCopper Plating SolutionCOPPER LPMU : 250 ml/l, B : 150 ml/l*As weak alkaline type, give almost no aging or etching base materials, and less formalin odor.*Less scratching to deposition film and good bath stability. *Can be applied for long period by replenishment method.TMP ELECTROLESS NICKELA : 160 ml/l, B : 160 ml/l*Economical as it is not necessary to throw away solution at replenishment owing to powder form.Alkaline ElectrolessNickel Plating SolutionPOWDER FORM NEW ELECTROLESSNICKEL RTTMP ELECTROLESS NICKEL CONCFor ReplenishmentFor Replenishment*High concentration type of TMP Electroless Nickel, which is used at exclusively replenishment.*As less dragging-out at replenishment, good in waste water treatment and running costs.ELECTROLESS NICKEL HR-TA : 150 ml/l, B : 150 ml/l*Excellent bath stability and low internal stress of the deposits.