BUFFING COMPOUND

BUFFING COMPOUND

BUFFING COMPOUND

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

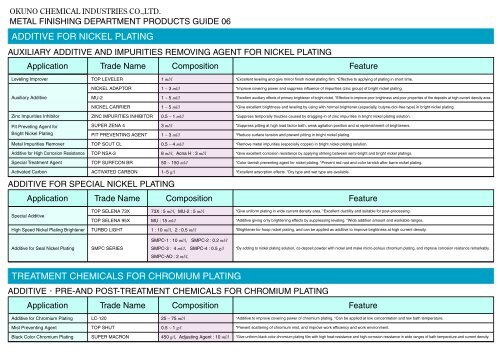

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 06ADDITIVE FOR NICKEL PLATINGAUXILIARY ADDITIVE AND IMPURITIES REMOVING AGENT FOR NICKEL PLATINGApplication Trade Name Composition FeatureLeveling ImproverTOP LEVELER1 ml/l*Excellent leveling and give mirror finish nickel plating film. *Effective to applying of plating in short time.NICKEL ADAPTOR1 ~ 3 ml/l*Improve covering power and suppress influence of impurities (zinc group) of bright nickel plating.Auxiliary AdditiveMU-21 ~ 5 ml/l*Excellent auxiliary effects of primary brightener of bright nickel. *Effective to improve poor brightness and poor properties of the deposits at high current density area.NICKEL CARRIER1 ~ 5 ml/l*Give excellent brightness and leveling by using with normal brightener (espacially, butyne-diol-free type) in bright nickel plating.Zinc Impurities InhibitorZINC IMPURITIES INHIBITOR0.5 ~ 1 ml/l*Suppress temporally troubles caused by dragging-in of zinc impurities in bright nickel plating solution.Pit Preveting Agent forSUPER ZENA 43 ml/l*Suppress pitting at high load factor bath, weak agitation position and at replenishment of brighteners.Bright Nickel PlatingPIT PREVENTING AGENT1 ~ 3 ml/l*Reduce surface tension and prevent pitting in bright nickel plating.Metal Impurities RemoverTOP SCUT CL0.5 ~ 4 ml/l*Remove metal impurities (especially copper) in bright nickel plating solution.Additive for High Corrosion ResistanceTOP NSA-38 ml/l, Acna H : 3 ml/l*Give excellent corrosion resistance by applying striking between semi-bright and bright nickel platings.Special Treatment AgentTOP SURFCON BR50 ~ 150 ml/l*Color tarnish preventing agent for nickel plating. *Prevent red rust and color tarnish after barre nickel plating.Activated CarbonACTIVATED CARBON1~5 g/l*Excellent adsorption effects. *Dry type and wet type are available.ADDITIVE FOR SPECIAL NICKEL PLATINGApplication Trade Name Composition FeatureSpecial AdditiveTOP SELENA 73XTOP SELENA 95X73X : 5 ml/l, MU-2 : 5 ml/lMU : 15 ml/l*Give uniform plating in wide current density area. *Excellent ductility and suitable for post-processing.*Additive giving only brightening effects by suppressing leveling. *Wide addition amount and workable ranges.High Speed Nickel Plating BrightenerTURBO LIGHT1 : 10 ml/l, 2 : 0.5 ml/l*Brightener for hoop nickel plating, and can be applied as additive to improve brightness at high current density.SMPC-1 : 10 ml/l, SMPC-2 : 0.2 ml/lAdditive for Seal Nickel PlatingSMPC SERIESSMPC-3 : 4 ml/l, SMPC-4 : 0.5 g/l*By adding to nickel plating solution, co-deposit powder with nickel and make micro-porous chromium plating, and improve corrosion reistance remarkably.SMPC-AD : 2 ml/l,TREATMENT CHEMICALS FOR CHROMIUM PLATINGADDITIVEPRE-AND POST-TREATMENT CHEMICALS FOR CHROMIUM PLATINGApplication Trade Name Composition FeatureAdditive for Chromium PlatingLC-12025 ~ 75 ml/l*Additive to improve covering power of chromium plating. *Can be applied at low concentration and low bath temperature.Mist Preventing AgentTOP SHUT0.5 ~ 1 g/l*Prevent scattering of chromium mist, and improve work efficiency and work environment.Black Color Chromium PlatingSUPER MACRON450 g/l, Adjusting Agent : 10 ml/l*Give uniform black color chromium plating film with high heat-resistance and high corrosion resistance in wide ranges of bath temperature and current density.