Conveyor Chain - Tsubaki

Conveyor Chain - Tsubaki

Conveyor Chain - Tsubaki

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

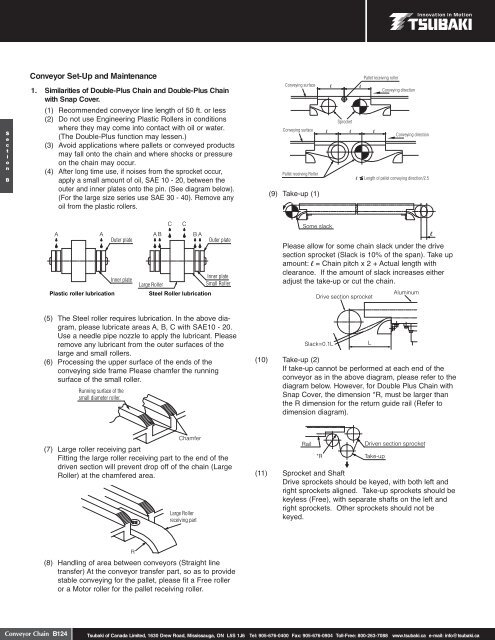

SectionB<strong>Conveyor</strong> Set-Up and Maintenance1. Similarities of Double-Plus <strong>Chain</strong> and Double-Plus <strong>Chain</strong>with Snap Cover.(1) Recommended conveyor line length of 50 ft. or less(2) Do not use Engineering Plastic Rollers in conditionswhere they may come into contact with oil or water.(The Double-Plus function may lessen.)(3) Avoid applications where pallets or conveyed productsmay fall onto the chain and where shocks or pressureon the chain may occur.(4) After long time use, if noises from the sprocket occur,apply a small amount of oil, SAE 10 - 20, between theouter and inner plates onto the pin. (See diagram below).(For the large size series use SAE 30 - 40). Remove anyoil from the plastic rollers.Conveying surfaceConveying surfacePallet receiving Roller(9) Take-up (1)llPallet receiving rollerConveying directionSprocketl l lConveying directionl Length of pallet conveying direction/2.5A A A BOuter platePlastic roller lubricationInner plateCCB AOuter plateInner plateLarge RollerSmall RollerSteel Roller lubricationSome slackPlease allow for some chain slack under the drivesection sprocket (Slack is 10% of the span). Take upamount: l = <strong>Chain</strong> pitch x 2 + Actual length withclearance. If the amount of slack increases eitheradjust the take-up or cut the chain.Drive section sprocketAluminuml(5) The Steel roller requires lubrication. In the above diagram,please lubricate areas A, B, C with SAE10 - 20.Use a needle pipe nozzle to apply the lubricant. Pleaseremove any lubricant from the outer surfaces of thelarge and small rollers.(6) Processing the upper surface of the ends of theconveying side frame Please chamfer the runningsurface of the small roller.Running surface of thesmall diameter roller.Slack=0.1L(10) Take-up (2)If take-up cannot be performed at each end of theconveyor as in the above diagram, please refer to thediagram below. However, for Double Plus <strong>Chain</strong> withSnap Cover, the dimension *R, must be larger thanthe R dimension for the return guide rail (Refer todimension diagram).LChamfer(7) Large roller receiving partFitting the large roller receiving part to the end of thedriven section will prevent drop off of the chain (LargeRoller) at the chamfered area.Large Rollerreceiving partRail*RDriven section sprocketTake-up(11) Sprocket and ShaftDrive sprockets should be keyed, with both left andright sprockets aligned. Take-up sprockets should bekeyless (Free), with separate shafts on the left andright sprockets. Other sprockets should not bekeyed.R(8) Handling of area between conveyors (Straight linetransfer) At the conveyor transfer part, so as to providestable conveying for the pallet, please fit a Free rolleror a Motor roller for the pallet receiving roller.<strong>Conveyor</strong> <strong>Chain</strong> B124<strong>Tsubaki</strong> of Canada Limited, 1630 Drew Road, Mississauga, ON L5S 1J6 Tel: 905-676-0400 Fax: 905-676-0904 Toll-Free: 800-263-7088 www.tsubaki.ca e-mail: info@tsubaki.ca