Conveyor Chain - Tsubaki

Conveyor Chain - Tsubaki

Conveyor Chain - Tsubaki

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

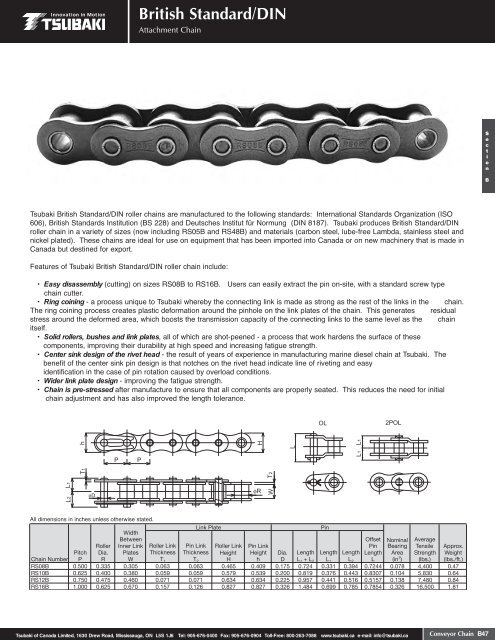

British Standard/DINAttachment <strong>Chain</strong>SectionB<strong>Tsubaki</strong> British Standard/DIN roller chains are manufactured to the following standards: International Standards Organization (ISO606), British Standards Institution (BS 228) and Deutsches Institut für Normung (DIN 8187). <strong>Tsubaki</strong> produces British Standard/DINroller chain in a variety of sizes (now including RS05B and RS48B) and materials (carbon steel, lube-free Lambda, stainless steel andnickel plated). These chains are ideal for use on equipment that has been imported into Canada or on new machinery that is made inCanada but destined for export.Features of <strong>Tsubaki</strong> British Standard/DIN roller chain include:• Easy disassembly (cutting) on sizes RS08B to RS16B. Users can easily extract the pin on-site, with a standard screw typechain cutter.• Ring coining - a process unique to <strong>Tsubaki</strong> whereby the connecting link is made as strong as the rest of the links in the chain.The ring coining process creates plastic deformation around the pinhole on the link plates of the chain. This generates residualstress around the deformed area, which boosts the transmission capacity of the connecting links to the same level as the chainitself.• Solid rollers, bushes and link plates, all of which are shot-peened - a process that work hardens the surface of thesecomponents, improving their durability at high speed and increasing fatigue strength.• Center sink design of the rivet head - the result of years of experience in manufacturing marine diesel chain at <strong>Tsubaki</strong>. Thebenefit of the center sink pin design is that notches on the rivet head indicate line of riveting and easyidentification in the case of pin rotation caused by overload conditions.• Wider link plate design - improving the fatigue strength.• <strong>Chain</strong> is pre-stressed after manufacture to ensure that all components are properly seated. This reduces the need for initialchain adjustment and has also improved the length tolerance.OL2POLhHLL1PPL1L2 L1T1φDφRW T2All dimensions in inches unless otherwise stated.RollerDia.RWidthBetweenInner LinkPlatesWRoller LinkThicknessPin LinkThicknessLink Plate PinRoller LinkHeightHPin LinkHeighthOffsetPinLengthLNominalBearingArea(in 2 )AverageTensileStrength(lbs.)PitchDia. Length Length Length<strong>Chain</strong> Number PT 1 T 2D L 1 + L 2 L 1 L 2RS08B 0.500 0.335 0.305 0.063 0.063 0.465 0.409 0.175 0.724 0.331 0.394 0.7244 0.078 4,400 0.47RS10B 0.625 0.400 0.380 0.059 0.059 0.579 0.539 0.200 0.819 0.376 0.443 0.8307 0.104 5,830 0.64RS12B 0.750 0.475 0.460 0.071 0.071 0.634 0.634 0.225 0.957 0.441 0.516 0.5157 0.138 7,480 0.84RS16B 1.000 0.625 0.670 0.157 0.126 0.827 0.827 0.326 1.484 0.699 0.785 0.7854 0.326 16,500 1.81Approx.Weight(lbs./ft.)<strong>Tsubaki</strong> of Canada Limited, 1630 Drew Road, Mississauga, ON L5S 1J6 Tel: 905-676-0400 Fax: 905-676-0904 Toll-Free: 800-263-7088 www.tsubaki.ca e-mail: info@tsubaki.ca<strong>Conveyor</strong> <strong>Chain</strong> B47