Conveyor Chain - Tsubaki

Conveyor Chain - Tsubaki

Conveyor Chain - Tsubaki

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

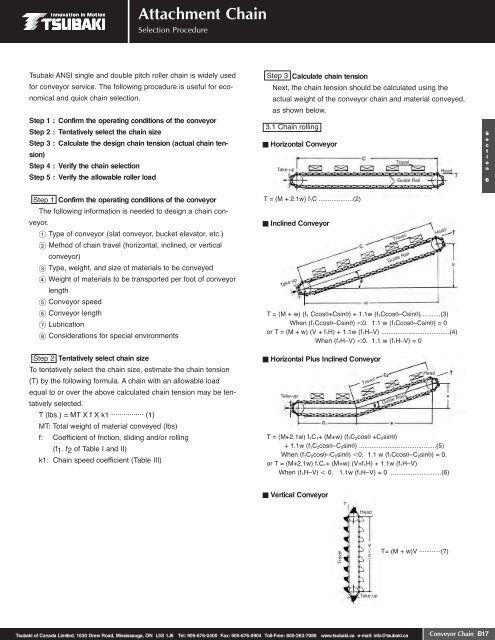

Attachment <strong>Chain</strong>Selection Procedure<strong>Tsubaki</strong> ANSI single and double pitch roller chain is widely usedfor conveyor service. The following procedure is useful for economicaland quick chain selection.Step 1 : Confirm the operating conditions of the conveyorStep 2 : Tentatively select the chain sizeStep 3 : Calculate the design chain tension (actual chain tension)Step 4 : Verify the chain selectionStep 5 : Verify the allowable roller loadStep 3 Calculate chain tensionNext, the chain tension should be calculated using theactual weight of the conveyor chain and material conveyed,as shown below.3.1 <strong>Chain</strong> rolling■ Horizontal <strong>Conveyor</strong>TravelTake-upHeadGuide RailSectionBStep 1 Confirm the operating conditions of the conveyorThe following information is needed to design a chain conveyor. Type of conveyor (slat conveyor, bucket elevator, etc.) Method of chain travel (horizontal, inclined, or verticalconveyor) Type, weight, and size of materials to be conveyed Weight of materials to be transported per foot of conveyorlength <strong>Conveyor</strong> speed <strong>Conveyor</strong> length Lubrication Considerations for special environmentsT = (M + 2.1w) f 1 C ...................(2)■ Inclined <strong>Conveyor</strong>Take-upTravelGuide RailHeadT = (M + w) (f 1 Ccosθ+Csinθ) + 1.1w (f 1 Ccosθ–Csinθ)...........(3)When (f 1 Ccosθ–Csinθ) 0. 1.1 w (f 1 Ccosθ–Csinθ) = 0or T = (M + w) (V + f 1 H) + 1.1w (f 1 H–V) ......................................(4)When (f 1 H–V) 0. 1.1 w (f 1 H–V) = 0Step 2 Tentatively select chain sizeTo tentatively select the chain size, estimate the chain tension(T) by the following formula. A chain with an allowable loadequal to or over the above calculated chain tension may be tentativelyselected.T (lbs.) = MT X f X k1 ................ (1)MT: Total weight of material conveyed (lbs)f: Coefficient of friction, sliding and/or rolling(f1. f2 of Table I and II)k1: <strong>Chain</strong> speed coefficient (Table III)■ Horizontal Plus Inclined <strong>Conveyor</strong>Take-upTravelGuide RailHeadT = (M+2.1w) f 1 C 1 + (M+w) (f 1 C 2 cosθ +C 2 sinθ)+ 1.1w (f 1 C 2 cosθ–C 2 sinθ) ...........................................(5)When (f 1 C 2 cosθ–C 2 sinθ) 0. 1.1 w (f 1 Ccosθ–C 2 sinθ) = 0.or T = (M+2.1w) f 1 C 1 + (M+w) (V+f 1 H) + 1.1w (f 1 H–V)When (f 1 H–V) 0. 1.1w (f 1 H–V) = 0 ............................(6)■ Vertical <strong>Conveyor</strong>THeadTravelT= (M + w)V ............ (7)Take-up<strong>Tsubaki</strong> of Canada Limited, 1630 Drew Road, Mississauga, ON L5S 1J6 Tel: 905-676-0400 Fax: 905-676-0904 Toll-Free: 800-263-7088 www.tsubaki.ca e-mail: info@tsubaki.ca<strong>Conveyor</strong> <strong>Chain</strong> B17