DTHC-SETUP/INSTALL MANUAL CandCNC

DTHC-SETUP/INSTALL MANUAL CandCNC

DTHC-SETUP/INSTALL MANUAL CandCNC

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

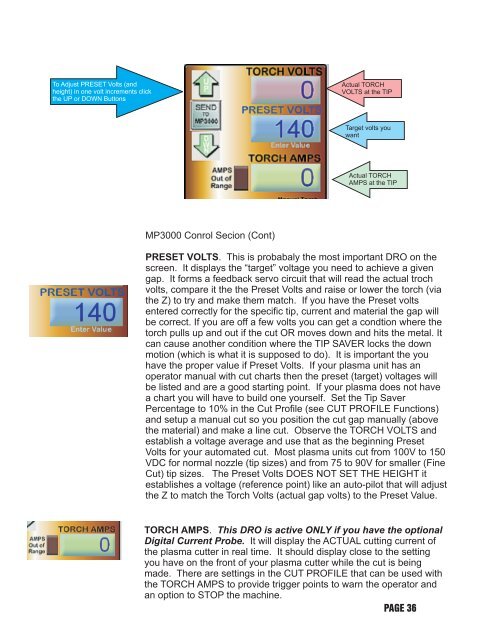

To Adjust PRESET Volts (andheight) in one volt increments clickthe UP or DOWN ButtonsActual TORCHVOLTS at the TIPTarget volts youwantActual TORCHAMPS at the TIPMP3000 Conrol Secion (Cont)PRESET VOLTS. This is probabaly the most important DRO on thescreen. It displays the “target” voltage you need to achieve a givengap. It forms a feedback servo circuit that will read the actual trochvolts, compare it the the Preset Volts and raise or lower the torch (viathe Z) to try and make them match. If you have the Preset voltsentered correctly for the specific tip, current and material the gap willbe correct. If you are off a few volts you can get a condtion where thetorch pulls up and out if the cut OR moves down and hits the metal. Itcan cause another condition where the TIP SAVER locks the downmotion (which is what it is supposed to do). It is important the youhave the proper value if Preset Volts. If your plasma unit has anoperator manual with cut charts then the preset (target) voltages willbe listed and are a good starting point. If your plasma does not havea chart you will have to build one yourself. Set the Tip SaverPercentage to 10% in the Cut Profile (see CUT PROFILE Functions)and setup a manual cut so you position the cut gap manually (abovethe material) and make a line cut. Observe the TORCH VOLTS andestablish a voltage average and use that as the beginning PresetVolts for your automated cut. Most plasma units cut from 100V to 150VDC for normal nozzle (tip sizes) and from 75 to 90V for smaller (FineCut) tip sizes. The Preset Volts DOES NOT SET THE HEIGHT itestablishes a voltage (reference point) like an auto-pilot that will adjustthe Z to match the Torch Volts (actual gap volts) to the Preset Value.TORCH AMPS. This DRO is active ONLY if you have the optionalDigital Current Probe. It will display the ACTUAL cutting current ofthe plasma cutter in real time. It should display close to the settingyou have on the front of your plasma cutter while the cut is beingmade. There are settings in the CUT PROFILE that can be used withthe TORCH AMPS to provide trigger points to warn the operator andan option to STOP the machine.PAGE 36