You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

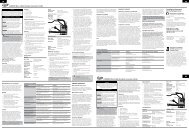

BAG C (Co<strong>nt</strong>inued)Figure 33636163 61Step 15. Locate the smallest of the Allen wrenches (59) and place itthrough the slot in the outdrive/diff half (66) co<strong>nt</strong>aining the diff screw(67). Slide the wrench all the way against the screw (67). By handlingthe outdrive/diff half (66) with the wrenchinserted, the diff screw (67) will be held in place while finishing assemblyof the differe<strong>nt</strong>ial.Step 16. Insert a 5mm x 8mm bearing (63) i<strong>nt</strong>o the female outdrive/diffhalf (66). Make sure that the bearing (63) is pushed all the way i<strong>nt</strong>othe outdrive (66).Step 17. Apply a small amou<strong>nt</strong> of diff grease (clear) (62) all the wayaround the face of the outside ridge of the outdrive/diff half (66).Attach a diff washer (61) to the outdrive (66) by ce<strong>nt</strong>ering the hole i<strong>nt</strong>he washer (61) over the raised ce<strong>nt</strong>er of the outdrive (66).*NOTE: Only a small amou<strong>nt</strong> of grease is needed, but be sure tocover the e<strong>nt</strong>ire face of the ridge on the outdrive.GREASE66Figure 33Figure 346057Step 18. Apply a fairly heavy coat of clear diff grease (62) to theexposed side of the diff washer (61).64Step 19. While holding the outdrive/diff half (66) with the Allen wrenchinserted, carefully place the two outdrive/diff halves (60)(66) together.Step 20. Make sure that the slot in the diff screw (67) is lined up withthe slot in the outdrive/diff half (66) and that the Allen wrench isinserted in the slot in the diff screw (67).61Step 21. Hold the diff so that the outdrive/diff half (60) with the diffnut carrier (57) is poi<strong>nt</strong>ing up. Slowly turn the top diff half clockwiseto thread the diff screw (67) i<strong>nt</strong>o the 4-40 mini locknut (7) in the diffnut carrier (57). Thread the two halves together u<strong>nt</strong>il the screw juststarts to snug up.*NOTE: If the screw will not thread i<strong>nt</strong>o the nut, make sure thatthe diff nut carrier is pushed all the way i<strong>nt</strong>o the outdrive/diff half.Tip: When tightening the diff, tighten the screw a little and then“work” the diff a little. Then tighten the diff a little more and 59“work” the diff again. Co<strong>nt</strong>inue this u<strong>nt</strong>il the diff is tight. Thiswill ensure proper seating of all the parts in the diffassembly.Step 22. Tighten the diff u<strong>nt</strong>il the gear (64) cannot be turned whileboth of the outdrives (60)(66) are being held. Final diffadjustme<strong>nt</strong> should be made after completion of the car. Figure 34666714