You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

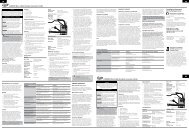

ENGINE INSTALLATIONNOTE: The following steps are shown with a “Side” Exhaust Engine.Other than the header, all mou<strong>nt</strong>ing of a “Rear” Exhaust Engine is the same.Figure 71152151151Step 1. Thread a clutch pin/screw (151) i<strong>nt</strong>o each of the small holes i<strong>nt</strong>he flywheel (152) and tighten with a .050" Allen wrench. The screwsshould be inserted from the rear as shown.Tip: A small amou<strong>nt</strong> of thread-lock compound should be used o<strong>nt</strong>he threads of the clutch pins.Figure 71Figure 72Step 2. Remove any hardware that came installed on the crankshaft ofyour engine. This includes all nuts, washers, and prop hubs.*NOTE: If your engine did not come with a glow plug you will needto purchase one. Use a glow plug wrench, or a 5/16" nut driver toinstall the glow plug i<strong>nt</strong>o the head of the engine. Most glow plugscome with a brass washer. Make sure that this washer is placed o<strong>nt</strong>he glow plug before it is installed.Figure 72Figure 73153Step 3. Slide a flywheel shim (153) over the crankshaft, and againstthe fro<strong>nt</strong> bearing on the engine. Slide the flywheel collet (154), largeside first, over the crankshaft and next to the shim (153).Tip: There are two shims included in the kit. If the flywheel i<strong>nt</strong>erfereswith the case of the engine, add a second shim. If after theengine is installed, the gears don't line up properly, a second shimcan be added to help correct the alignme<strong>nt</strong>.Step 4. Slide the flywheel (152), pins out, over the crankshaft. Theflywheel (152) should be seated over the collet (154). Thread theclutch nut (155) o<strong>nt</strong>o the crankshaft and tighten it using a 3/32"Allen wrench.152154153IMPORTANT NOTE: The clutch nut should be very tight.Hold the flywheel with a rag in order to get a good grip while tighteningthe clutch nut. There are special tools available for inserting in thehead of the engine to keep it from turning over while tightening theclutch nut. Other than these special tools, nothing should ever beinserted in the head of the engine to keep it from turning over!3 2155Figure 73