Mini-Space Series Installation, Operation & Maintenance Manual

Mini-Space Series Installation, Operation & Maintenance Manual

Mini-Space Series Installation, Operation & Maintenance Manual

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

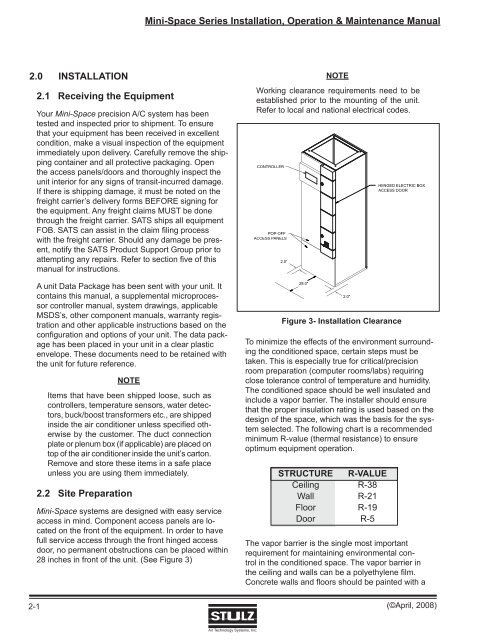

<strong>Mini</strong>-<strong>Space</strong> <strong>Series</strong> <strong>Installation</strong>, <strong>Operation</strong> & <strong>Maintenance</strong> <strong>Manual</strong>2.0 INSTALLATION2-12.1 Receiving the EquipmentYour <strong>Mini</strong>-<strong>Space</strong> precision A/C system has beentested and inspected prior to shipment. To ensurethat your equipment has been received in excellentcondition, make a visual inspection of the equipmentimmediately upon delivery. Carefully remove the shippingcontainer and all protective packaging. Openthe access panels/doors and thoroughly inspect theunit interior for any signs of transit-incurred damage.If there is shipping damage, it must be noted on thefreight carrier’s delivery forms BEFORE signing forthe equipment. Any freight claims MUST be donethrough the freight carrier. SATS ships all equipmentFOB. SATS can assist in the claim filing processwith the freight carrier. Should any damage be present,notify the SATS Product Support Group prior toattempting any repairs. Refer to section five of thismanual for instructions.A unit Data Package has been sent with your unit. Itcontains this manual, a supplemental microprocessorcontroller manual, system drawings, applicableMSDS’s, other component manuals, warranty registrationand other applicable instructions based on theconfiguration and options of your unit. The data packagehas been placed in your unit in a clear plasticenvelope. These documents need to be retained withthe unit for future reference.NOTEItems that have been shipped loose, such ascontrollers, temperature sensors, water detectors,buck/boost transformers etc., are shippedinside the air conditioner unless specifi ed otherwiseby the customer. The duct connectionplate or plenum box (if applicable) are placed ontop of the air conditioner inside the unit’s carton.Remove and store these items in a safe placeunless you are using them immediately.2.2 Site Preparation<strong>Mini</strong>-<strong>Space</strong> systems are designed with easy serviceaccess in mind. Component access panels are locatedon the front of the equipment. In order to havefull service access through the front hinged accessdoor, no permanent obstructions can be placed within28 inches in front of the unit. (See Figure 3)NOTEWorking clearance requirements need to beestablished prior to the mounting of the unit.Refer to local and national electrical codes.CONTROLLERPOP-OFFACCESS PANELS2.0"28.0"Figure 3- <strong>Installation</strong> ClearanceTo minimize the effects of the environment surroundingthe conditioned space, certain steps must betaken. This is especially true for critical/precisionroom preparation (computer rooms/labs) requiringclose tolerance control of temperature and humidity.The conditioned space should be well insulated andinclude a vapor barrier. The installer should ensurethat the proper insulation rating is used based on thedesign of the space, which was the basis for the systemselected. The following chart is a recommendedminimum R-value (thermal resistance) to ensureoptimum equipment operation.STRUCTURE R-VALUECeiling R-38Wall R-21Floor R-19Door R-5HIINGED ELECTRIC BOXACCESS DOORThe vapor barrier is the single most importantrequirement for maintaining environmental controlin the conditioned space. The vapor barrier inthe ceiling and walls can be a polyethylene fi lm.Concrete walls and fl oors should be painted with a2.0"(©April, 2008)Air Technology Systems, Inc.