Mini-Space Series Installation, Operation & Maintenance Manual

Mini-Space Series Installation, Operation & Maintenance Manual

Mini-Space Series Installation, Operation & Maintenance Manual

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

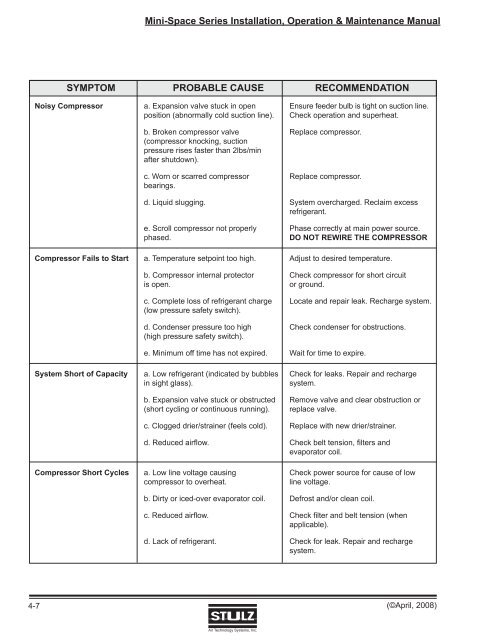

<strong>Mini</strong>-<strong>Space</strong> <strong>Series</strong> <strong>Installation</strong>, <strong>Operation</strong> & <strong>Maintenance</strong> <strong>Manual</strong>SYMPTOM PROBABLE CAUSE RECOMMENDATIONNoisy Compressor a. Expansion valve stuck in open Ensure feeder bulb is tight on suction line.position (abnormally cold suction line). Check operation and superheat.b. Broken compressor valve Replace compressor.(compressor knocking, suctionpressure rises faster than 2lbs/minafter shutdown).c. Worn or scarred compressor Replace compressor.bearings.d. Liquid slugging. System overcharged. Reclaim excessrefrigerant.e. Scroll compressor not properly Phase correctly at main power source.phased.DO NOT REWIRE THE COMPRESSORCompressor Fails to Start a. Temperature setpoint too high. Adjust to desired temperature.b. Compressor internal protector Check compressor for short circuitis open.or ground.c. Complete loss of refrigerant charge Locate and repair leak. Recharge system.(low pressure safety switch).d. Condenser pressure too high Check condenser for obstructions.(high pressure safety switch).e. <strong>Mini</strong>mum off time has not expired. Wait for time to expire.System Short of Capacity a. Low refrigerant (indicated by bubbles Check for leaks. Repair and rechargein sight glass).system.b. Expansion valve stuck or obstructed Remove valve and clear obstruction or(short cycling or continuous running). replace valve.c. Clogged drier/strainer (feels cold). Replace with new drier/strainer.d. Reduced airfl ow. Check belt tension, filters andevaporator coil.Compressor Short Cycles a. Low line voltage causing Check power source for cause of lowcompressor to overheat.line voltage.b. Dirty or iced-over evaporator coil. Defrost and/or clean coil.c. Reduced airfl ow. Check filter and belt tension (whenapplicable).d. Lack of refrigerant. Check for leak. Repair and rechargesystem.4-7(©April, 2008)Air Technology Systems, Inc.