Fusion Programme - ENEA - Fusione

Fusion Programme - ENEA - Fusione

Fusion Programme - ENEA - Fusione

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

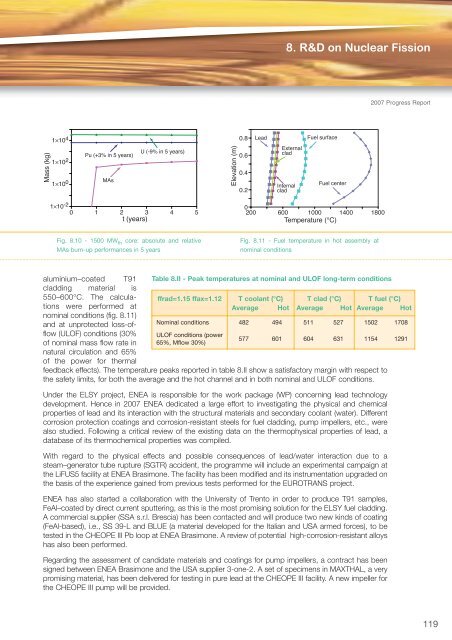

8. R&D on Nuclear Fission2007 Progress ReportMass (kg)1×10 41×10 21×10 0Pu (+3% in 5 years)MAsU (-9% in 5 years)Elevation (m)0.80.60.40.2LeadExternalcladInternalcladFuel surfaceFuel center1×10 -20 1 2 3 4 5t (years)0200600 1000 1400Temperature (°C)1800Fig. 8.10 - 1500 MW th core: absolute and relativeMAs burn-up performances in 5 yearsFig. 8.11 - Fuel temperature in hot assembly atnominal conditionsaluminium–coated T91cladding material is550–600°C. The calcula -tions were performed atnominal conditions (fig. 8.11)and at unprotected loss-offlow(ULOF) conditions (30%of nominal mass flow rate innatural circulation and 65%of the power for thermalTable 8.II - Peak temperatures at nominal and ULOF long-term conditionsffrad=1.15 ffax=1.12T coolant (°C)Average HotT clad (°C)Average HotT fuel (°C)Average HotNominal conditions 482 494 511 527 1502 1708ULOF conditions (power65%, Mflow 30%)577 601 604 631 1154 1291feedback effects). The temperature peaks reported in table 8.II show a satisfactory margin with respect tothe safety limits, for both the average and the hot channel and in both nominal and ULOF conditions.Under the ELSY project, <strong>ENEA</strong> is responsible for the work package (WP) concerning lead technologydevelopment. Hence in 2007 <strong>ENEA</strong> dedicated a large effort to investigating the physical and chemicalproperties of lead and its interaction with the structural materials and secondary coolant (water). Differentcorrosion protection coatings and corrosion-resistant steels for fuel cladding, pump impellers, etc., werealso studied. Following a critical review of the existing data on the thermophysical properties of lead, adatabase of its thermochemical properties was compiled.With regard to the physical effects and possible consequences of lead/water interaction due to asteam–generator tube rupture (SGTR) accident, the programme will include an experimental campaign atthe LiFUS5 facility at <strong>ENEA</strong> Brasimone. The facility has been modified and its instrumentation upgraded onthe basis of the experience gained from previous tests performed for the EUROTRANS project.<strong>ENEA</strong> has also started a collaboration with the University of Trento in order to produce T91 samples,FeAl–coated by direct current sputtering, as this is the most promising solution for the ELSY fuel cladding.A commercial supplier (SSA s.r.l. Brescia) has been contacted and will produce two new kinds of coating(FeAl-based), i.e., SS 39-L and BLUE (a material developed for the Italian and USA armed forces), to betested in the CHEOPE III Pb loop at <strong>ENEA</strong> Brasimone. A review of potential high-corrosion-resistant alloyshas also been performed.Regarding the assessment of candidate materials and coatings for pump impellers, a contract has beensigned between <strong>ENEA</strong> Brasimone and the USA supplier 3-one-2. A set of specimens in MAXTHAL, a verypromising material, has been delivered for testing in pure lead at the CHEOPE III facility. A new impeller forthe CHEOPE III pump will be provided.119