Fusion Programme - ENEA - Fusione

Fusion Programme - ENEA - Fusione

Fusion Programme - ENEA - Fusione

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

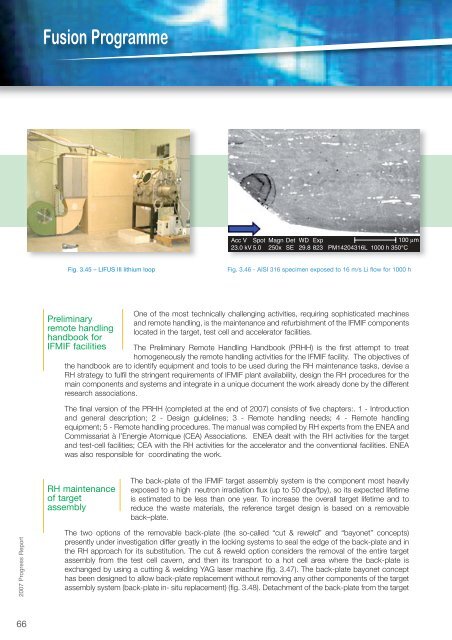

<strong>Fusion</strong> <strong>Programme</strong>Acc V Spot Magn Det WD Exp100 μm23.0 kV 5.0 250x SE 29.8 823 PM14204316L 1000 h 350°CFig. 3.45 – LIFUS III lithium loopFig. 3.46 - AISI 316 specimen exposed to 16 m/s Li flow for 1000 hPreliminaryremote handlinghandbook forIFMIF facilitiesOne of the most technically challenging activities, requiring sophisticated machinesand remote handling, is the maintenance and refurbishment of the IFMIF componentslocated in the target, test cell and accelerator facilities.The Preliminary Remote Handling Handbook (PRHH) is the first attempt to treathomogeneously the remote handling activities for the IFMIF facility. The objectives ofthe handbook are to identify equipment and tools to be used during the RH maintenance tasks, devise aRH strategy to fulfil the stringent requirements of IFMIF plant availability, design the RH procedures for themain components and systems and integrate in a unique document the work already done by the differentresearch associations.The final version of the PRHH (completed at the end of 2007) consists of five chapters:. 1 - Introductionand general description; 2 - Design guidelines; 3 - Remote handling needs; 4 - Remote handlingequipment; 5 - Remote handling procedures. The manual was compiled by RH experts from the <strong>ENEA</strong> andCommissariat à l’Energie Atomique (CEA) Associations. <strong>ENEA</strong> dealt with the RH activities for the targetand test-cell facilities; CEA with the RH activities for the accelerator and the conventional facilities. <strong>ENEA</strong>was also responsible for coordinating the work.RH maintenanceof targetassemblyThe back-plate of the IFMIF target assembly system is the component most heavilyexposed to a high neutron irradiation flux (up to 50 dpa/fpy), so its expected lifetimeis estimated to be less than one year. To increase the overall target lifetime and toreduce the waste materials, the reference target design is based on a removableback–plate.2007 Progress ReportThe two options of the removable back-plate (the so-called “cut & reweld” and “bayonet” concepts)presently under investigation differ greatly in the locking systems to seal the edge of the back-plate and inthe RH approach for its substitution. The cut & reweld option considers the removal of the entire targetassembly from the test cell cavern, and then its transport to a hot cell area where the back-plate isexchanged by using a cutting & welding YAG laser machine (fig. 3.47). The back-plate bayonet concepthas been designed to allow back-plate replacement without removing any other components of the targetassembly system (back-plate in- situ replacement) (fig. 3.48). Detachment of the back-plate from the target66