Fusion Programme - ENEA - Fusione

Fusion Programme - ENEA - Fusione

Fusion Programme - ENEA - Fusione

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

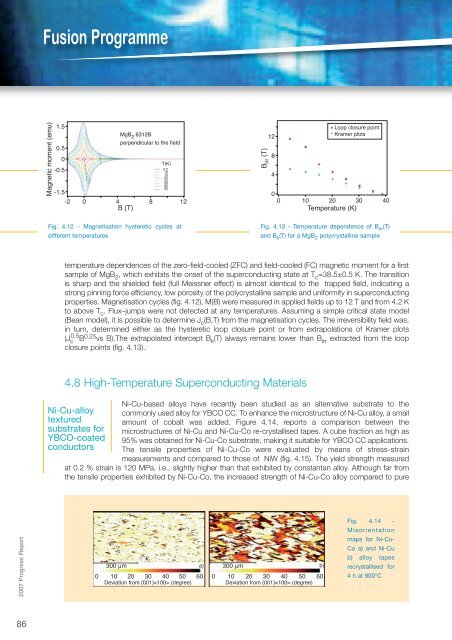

<strong>Fusion</strong> <strong>Programme</strong>Magnetic moment (emu)1.50.50-0.5-1.5MgB 2 6312Bperpendicular to the fieldT(K)4.210152025303555-2 0 4 8 12B (T)B irr (T)1284Loop closure pointKramer plots00 10 20 30 40Temperature (K)Fig. 4.12 - Magnetisation hysteretic cycles atdifferent temperaturesFig. 4.13 - Temperature dependence of B irr (T)and B k (T) for a MgB 2 polycrystalline sampletemperature dependences of the zero-field-cooled (ZFC) and field-cooled (FC) magnetic moment for a firstsample of MgB 2 , which exhibits the onset of the superconducting state at T c =38.5±0.5 K. The transitionis sharp and the shielded field (full Meissner effect) is almost identical to the trapped field, indicating astrong pinning force efficiency, low porosity of the polycrystalline sample and uniformity in superconductingproperties. Magnetisation cycles (fig. 4.12), M(B) were measured in applied fields up to 12 T and from 4.2 Kto above T c . Flux–jumps were not detected at any temperatures. Assuming a simple critical state model(Bean model), it is possible to determine J c (B,T) from the magnetisation cycles. The irreversibility field was,in turn, determined either as the hysteretic loop closure point or from extrapolations of Kramer plots(J c 0.5 B 0.25 vs B).The extrapolated intercept B k (T) always remains lower than B irr extracted from the loopclosure points (fig. 4.13).4.8 High-Temperature Superconducting MaterialsNi-Cu-based alloys have recently been studied as an alternative substrate to theNi-Cu-alloy commonly used alloy for YBCO CC. To enhance the microstructure of Ni-Cu alloy, a smalltexturedamount of cobalt was added. Figure 4.14, reports a comparison between thesubstrates for microstructures of Ni-Cu and Ni-Cu-Co re-crystallised tapes. A cube fraction as high asYBCO-coated 95% was obtained for Ni-Cu-Co substrate, making it suitable for YBCO CC applications.conductors The tensile properties of Ni-Cu-Co were evaluated by means of stress-strainmeasurements and compared to those of NiW (fig. 4.15). The yield strength measuredat 0.2 % strain is 120 MPa, i.e., slightly higher than that exhibited by constantan alloy. Although far fromthe tensile properties exhibited by Ni-Cu-Co, the increased strength of Ni-Cu-Co alloy compared to pure2007 Progress Report300 μm a) 300 μmb)0 10 20 30 40 50 60 0 10 20 30 40 50 60Deviation from {001} (degree)Deviation from {001} (degree)Fig. 4.14 -Misorientationmaps for Ni-Cu-Co a) and Ni-Cub) alloy tapesrecrystallised for4 h at 900°C86