- Page 1 and 2:

PROGRESS REPORT2007Nuclear Fusion a

- Page 3 and 4:

ContentsPART I - FUSION PROGRAMME 7

- Page 5 and 6:

2007PART IV - MISCELLANEOUS 18314.

- Page 7:

2007analyses of the missions to be

- Page 10 and 11:

Fusion Programme2007 Progress Repor

- Page 12 and 13:

Fusion ProgrammeTable 1.I - Summary

- Page 14 and 15:

Fusion ProgrammeFollowing a Europea

- Page 16 and 17: Fusion Programmen e (10 20 m -3 )3.

- Page 18 and 19: Fusion Programme2007 Progress Repor

- Page 20 and 21: Fusion Programmewas not affected by

- Page 22 and 23: Fusion ProgrammeShear Alfvén wavec

- Page 24 and 25: Fusion Programmen H (10 20 /m 3 )0.

- Page 26 and 27: Fusion Programmei.e., typically, ra

- Page 28 and 29: Fusion ProgrammeENEA has provided t

- Page 30 and 31: Fusion Programmennα6 LIF6 LIF9 BeI

- Page 32 and 33: Fusion Programme2007 Progress Repor

- Page 34 and 35: Fusion Programmedifference between

- Page 36 and 37: Fusion ProgrammeIntroductionThe suc

- Page 38 and 39: Fusion ProgrammeMinority ions, acce

- Page 40 and 41: Fusion ProgrammeThe cryostat overal

- Page 42 and 43: Fusion ProgrammeIntroductionThe tec

- Page 44 and 45: Fusion ProgrammeThe main results so

- Page 46 and 47: Fusion ProgrammeInfrared absorption

- Page 48 and 49: Fusion ProgrammeFig. 3.8 - Frascati

- Page 50 and 51: Fusion ProgrammeThe second year of

- Page 52 and 53: 250Fusion Programmeflow-rate in the

- Page 54 and 55: Fusion ProgrammeThe aim of the work

- Page 56 and 57: Fusion ProgrammeFig. 3.21 - X-ray s

- Page 58 and 59: Fusion ProgrammeRange (mm)593583573

- Page 60 and 61: Fusion ProgrammeZ (m)6420-2-4-6sour

- Page 62 and 63: Fusion Programmea) b)c)Fig. 3.31 -

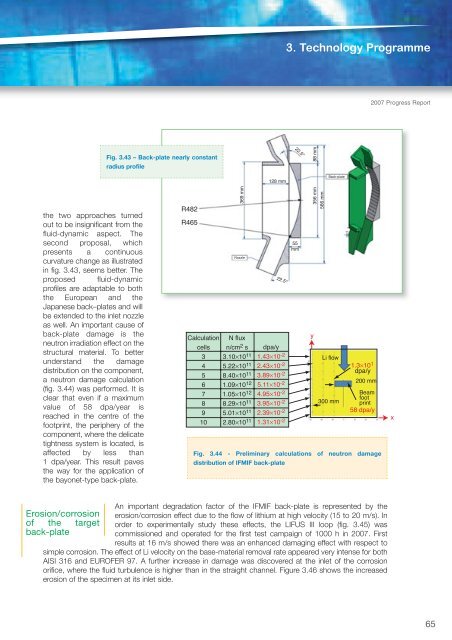

- Page 64 and 65: Fusion Programmeactivation. Eight r

- Page 68 and 69: Fusion ProgrammeAcc V Spot Magn Det

- Page 70 and 71: Fusion Programmelubricants cannot b

- Page 72 and 73: Fusion ProgrammeTritium roomTritium

- Page 74 and 75: Fusion ProgrammeImplications for PS

- Page 76 and 77: Fusion ProgrammeThe development and

- Page 78 and 79: Fusion ProgrammeIntroductionDuring

- Page 80 and 81: Fusion Programme19.5Section view B-

- Page 82 and 83: Fusion Programmeresults and particu

- Page 84 and 85: Fusion ProgrammeFollowing the exten

- Page 86 and 87: Fusion Programme4.7 Characterisatio

- Page 88 and 89: Fusion ProgrammeMagnetic moment (em

- Page 90 and 91: Fusion ProgrammeCeO 2YSZCeO 2YBCOMa

- Page 92 and 93: Fusion Programme0 1 10 0 1 100 1 10

- Page 94 and 95: Fusion ProgrammeLoad (mN)0.80.60.40

- Page 96 and 97: Fusion Programme5.1 Outline and Ove

- Page 98 and 99: Fusion Programme(λ D /Δ 0 ) 2Δ 0

- Page 101 and 102: 5. Inertial Fusion2007 Progress Rep

- Page 103 and 104: 6. Communication and Relationswith

- Page 105 and 106: 7. Publications and Events - Fusion

- Page 107 and 108: 7. Publications and Events - Fusion

- Page 109 and 110: 7. Publications and Events - Fusion

- Page 111 and 112: 7. Publications and Events - Fusion

- Page 113: 7. Publications and Events - Fusion

- Page 116 and 117:

Fission Technology8.1 Advanced and

- Page 118 and 119:

Fission TechnologyAcceleration m/s

- Page 120 and 121:

Fission Technology232.73 mm (17 pin

- Page 122 and 123:

Fission TechnologyThe Very High Tem

- Page 124 and 125:

Fission Technology500Thermocouple t

- Page 126 and 127:

Fission Technology0.16 mm 0.16 mm0.

- Page 128 and 129:

Fission Technology-4800-85000.00SGU

- Page 130 and 131:

Fission Technologythrough calculati

- Page 132 and 133:

Fission Technology1.23 e+001.17 e+0

- Page 134 and 135:

Fission TechnologyPressure (bar)642

- Page 136 and 137:

Fission TechnologyFig. 8.37 - Creep

- Page 138 and 139:

Fission TechnologyENEA organised th

- Page 140 and 141:

Fission TechnologyTemperature600400

- Page 142 and 143:

Fission TechnologyZ(m)1.00.80.60.40

- Page 144 and 145:

Fission Technologythat a system is

- Page 146 and 147:

Fission TechnologyMaxwellian-averag

- Page 148 and 149:

Fission TechnologyBOT3P has large w

- Page 150 and 151:

Fission Technology9.1 Boron Neutron

- Page 152 and 153:

Fission TechnologyIn collaboration

- Page 154 and 155:

Fission Technologyvolume. Thus the

- Page 156 and 157:

Fission TechnologyFig. 9.9 - Logger

- Page 158 and 159:

Fission TechnologyIn relation to EN

- Page 160 and 161:

Fission TechnologyArticles11.1 Publ

- Page 162 and 163:

Fission TechnologyArticles incourse

- Page 164 and 165:

Fission TechnologyF. ROELOFS, B. DE

- Page 166 and 167:

Fission TechnologyE. BERTHOUMIEUX e

- Page 168 and 169:

Fission TechnologyInternal reportsR

- Page 170 and 171:

Fission TechnologyRTI FPN-P815-008

- Page 173 and 174:

PART IIINUCLEAR PROTECTION171

- Page 175 and 176:

12. Radioactive Waste Management an

- Page 177 and 178:

12. Radioactive Waste Management an

- Page 179 and 180:

12. Radioactive Waste Management an

- Page 181 and 182:

12. Radioactive Waste Management an

- Page 183:

13. Publications - Nuclear Protecti

- Page 186 and 187:

Miscellaneous14.1 Advances in the I

- Page 188 and 189:

Miscellaneoususing a full wave code

- Page 190 and 191:

MiscellaneousAt present the effect

- Page 192 and 193:

MiscellaneousSuperAGILE view of the

- Page 194 and 195:

Abbreviations and AcronymsAacACPADS

- Page 196 and 197:

Abbreviations and AcronymsEFITEHRSE

- Page 198 and 199:

Abbreviations and AcronymsITERITGIT

- Page 200 and 201:

Abbreviations and AcronymsPFWPGAPHY

- Page 202:

Abbreviations and AcronymsVVDEVELLA