Fusion Programme - ENEA - Fusione

Fusion Programme - ENEA - Fusione

Fusion Programme - ENEA - Fusione

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

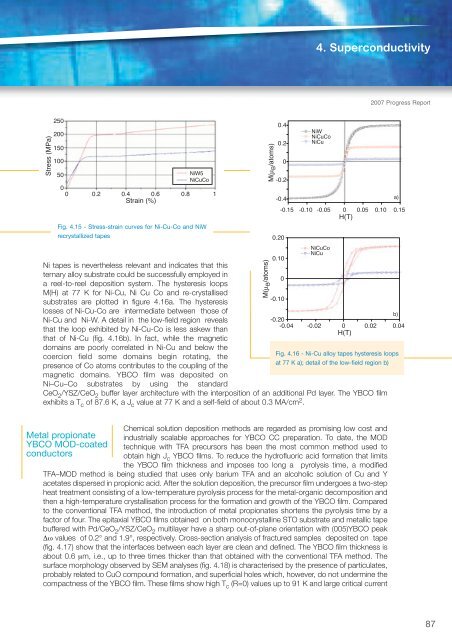

4. Superconductivity2007 Progress ReportStress (MPa)25020015010050NiW5NiCuCo00 0.2 0.4 0.6 0.8 1Strain (%)Fig. 4.15 - Stress-strain curves for Ni-Cu-Co and NiWrecrystallized tapesNi tapes is nevertheless relevant and indicates that thisternary alloy substrate could be successfully employed ina reel-to-reel deposition system. The hysteresis loops0M(H) at 77 K for Ni-Cu, Ni Cu Co and re-crystallisedsubstrates are plotted in figure 4.16a. The hysteresis-0.10losses of Ni-Cu-Co are intermediate between those ofb)Ni-Cu and Ni-W. A detail in the low-field region reveals-0.20-0.04 -0.02 0 0.02 0.04that the loop exhibited by Ni-Cu-Co is less askew thanH(T)that of Ni-Cu (fig. 4.16b). In fact, while the magneticdomains are poorly correlated in Ni-Cu and below thecoercion field some domains begin rotating, thepresence of Co atoms contributes to the coupling of theFig. 4.16 - Ni-Cu alloy tapes hysteresis loopsat 77 K a); detail of the low-field region b)magnetic domains. YBCO film was deposited onNi–Cu–Co substrates by using the standardCeO 2 /YSZ/CeO 2 buffer layer architecture with the interposition of an additional Pd layer. The YBCO filmexhibits a T c of 87.6 K, a J c value at 77 K and a self-field of about 0.3 MA/cm 2 .M(μ B /atoms)M(μ B /atoms)0.40.20-0.2-0.40.200.10NiWNiCuCoNiCu-0.15 -0.10 -0.05 0 0.05 0.10 0.15H(T)NiCuCoNiCua)Chemical solution deposition methods are regarded as promising low cost andMetal propionate industrially scalable approaches for YBCO CC preparation. To date, the MODYBCO MOD-coated technique with TFA precursors has been the most common method used toconductorsobtain high J c YBCO films. To reduce the hydrofluoric acid formation that limitsthe YBCO film thickness and imposes too long a pyrolysis time, a modifiedTFA–MOD method is being studied that uses only barium TFA and an alcoholic solution of Cu and Yacetates dispersed in propionic acid. After the solution deposition, the precursor film undergoes a two-stepheat treatment consisting of a low-temperature pyrolysis process for the metal-organic decomposition andthen a high-temperature crystallisation process for the formation and growth of the YBCO film. Comparedto the conventional TFA method, the introduction of metal propionates shortens the pyrolysis time by afactor of four. The epitaxial YBCO films obtained on both monocrystalline STO substrate and metallic tapebuffered with Pd/CeO 2 /YSZ/CeO 2 multilayer have a sharp out-of-plane orientation with (005)YBCO peakΔω values of 0.2° and 1.9°, respectively. Cross-section analysis of fractured samples deposited on tape(fig. 4.17) show that the interfaces between each layer are clean and defined. The YBCO film thickness isabout 0.6 μm, i.e., up to three times thicker than that obtained with the conventional TFA method. Thesurface morphology observed by SEM analyses (fig. 4.18) is characterised by the presence of particulates,probably related to CuO compound formation, and superficial holes which, however, do not undermine thecompactness of the YBCO film. These films show high T c (R=0) values up to 91 K and large critical current87