Fusion Programme - ENEA - Fusione

Fusion Programme - ENEA - Fusione

Fusion Programme - ENEA - Fusione

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

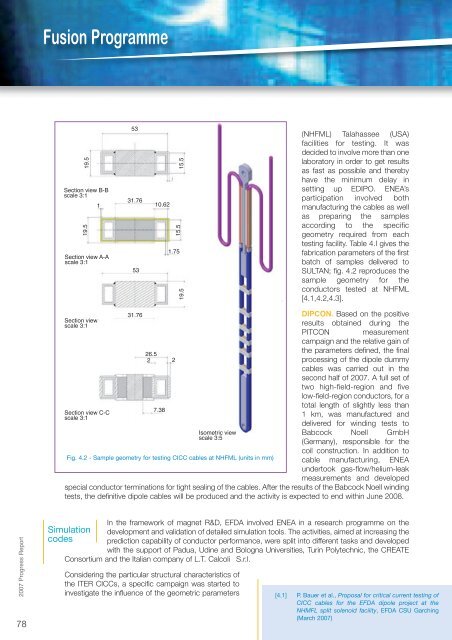

<strong>Fusion</strong> <strong>Programme</strong>19.5Section view B-Bscale 3:119.51Section view A-Ascale 3:15331.765310.6215.519.5 15.51.75(NHFML) Talahassee (USA)facilities for testing. It wasdecided to involve more than onelaboratory in order to get resultsas fast as possible and therebyhave the minimum delay insetting up EDIPO. <strong>ENEA</strong>’sparticipation involved bothmanufacturing the cables as wellas preparing the samplesaccording to the specificgeometry required from eachtesting facility. Table 4.I gives thefabrication parameters of the firstbatch of samples delivered toSULTAN; fig. 4.2 reproduces thesample geometry for theconductors tested at NHFML[4.1,4.2,4.3].Section viewscale 3:1Section view C-Cscale 3:131.7626.52 27.38Isometric viewscale 3:5Fig. 4.2 - Sample geometry for testing CICC cables at NHFML (units in mm)DIPCON. Based on the positiveresults obtained during thePITCON measurementcampaign and the relative gain ofthe parameters defined, the finalprocessing of the dipole dummycables was carried out in thesecond half of 2007. A full set oftwo high-field-region and fivelow-field-region conductors, for atotal length of slightly less than1 km, was manufactured anddelivered for winding tests toBabcock Noell GmbH(Germany), responsible for thecoil construction. In addition tocable manufacturing, <strong>ENEA</strong>undertook gas-flow/helium-leakmeasurements and developedspecial conductor terminations for tight sealing of the cables. After the results of the Babcock Noell windingtests, the definitive dipole cables will be produced and the activity is expected to end within June 2008.2007 Progress Report78In the framework of magnet R&D, EFDA involved <strong>ENEA</strong> in a research programme on theSimulation development and validation of detailed simulation tools. The activities, aimed at increasing thecodes prediction capability of conductor performance, were split into different tasks and developedwith the support of Padua, Udine and Bologna Universities, Turin Polytechnic, the CREATEConsortium and the Italian company of L.T. Calcoli S.r.l.Considering the particular structural characteristics ofthe ITER CICCs, a specific campaign was started toinvestigate the influence of the geometric parameters[4.1] P. Bauer et al., Proposal for critical current testing ofCICC cables for the EFDA dipole project at theNHMFL split solenoid facility, EFDA CSU Garching(March 2007)