- Page 1:

ATSB TRANSPORT SAFETY REPORTAviatio

- Page 4 and 5:

Published by: Australian Transport

- Page 6 and 7:

3 FACTUAL INFORMATION: AIR DATA INE

- Page 9 and 10:

DOCUMENT RETRIEVAL INFORMATIONRepor

- Page 11:

TERMINOLOGY USED IN THIS REPORTOccu

- Page 14 and 15:

CSMCSSCVRDADSDCDGACDMCDMUEASAECAMED

- Page 16 and 17:

RAMRTCASATCOMSAESAOSDSECSEESEUSSASS

- Page 18 and 19:

FCPC design limitationAOA is a crit

- Page 20 and 21:

- xviii -

- Page 22 and 23:

associated with a master caution ch

- Page 24 and 25:

Figure 2: Aircraft track and key ev

- Page 26 and 27:

The crew decided that they needed t

- Page 28 and 29:

1.3 Damage to aircraftThere was sig

- Page 30 and 31:

• The flight crew provided inputs

- Page 32 and 33:

exceeding a predefined safe flight

- Page 34 and 35:

Table 1: Examples of ADIRU flight d

- Page 36 and 37:

Inertial reference partThe IR part

- Page 38 and 39:

ADIRS switching controlsIn normal o

- Page 40 and 41:

Processing by ADIRUs and FCPCsEach

- Page 42 and 43:

The information presented on the fl

- Page 44 and 45:

A system could flag its output data

- Page 46 and 47:

Table 4: Summary of indications for

- Page 48 and 49:

Figure 17: ECAM engine / warning di

- Page 50 and 51:

Table 6: Required actions associate

- Page 52 and 53:

For internal aircraft communication

- Page 54 and 55:

Table 7: Sequence of events (from t

- Page 56 and 57:

In summary, the source of most of t

- Page 58 and 59:

Summary of IR data for the occurren

- Page 60 and 61:

Figure 22: QAR plot showing oscilla

- Page 62 and 63:

QAR dataOverall, the QAR recorded 4

- Page 64 and 65:

Flight crew pitch inputsDuring manu

- Page 66 and 67:

They provided information for maint

- Page 68 and 69:

Table 11: Cockpit effect messages d

- Page 70 and 71:

Table 13: Troubleshooting data rela

- Page 72 and 73:

position 1 on QPA. Further details

- Page 74 and 75:

class 1 fault messages shown in Tab

- Page 76 and 77:

If there was a discrepancy between

- Page 78 and 79:

1.15 Survival aspectsInformation on

- Page 80 and 81:

did not identify any faults. The BI

- Page 82 and 83:

Comparison of the three occurrences

- Page 84 and 85:

1.17.2 Processes for reporting and

- Page 87 and 88:

2 FACTUAL INFORMATION: ELECTRICAL F

- Page 89 and 90:

monitored external systems that pro

- Page 91 and 92:

Each FCPC used a number of paramete

- Page 93 and 94:

AOA computation logicThe FCPC softw

- Page 95 and 96:

Figure 29: FCPC processing of sever

- Page 97 and 98:

Table 19: Characteristics of elevat

- Page 99 and 100:

Simulation of AOA values for the fi

- Page 101 and 102:

2.2.2 Review of recorded flight con

- Page 103 and 104:

second PRIM 3 FAULT. The role of ma

- Page 105 and 106:

The ACJ was built around the princi

- Page 107 and 108:

• It stated that the identificati

- Page 109 and 110:

The second part of the V-cycle invo

- Page 111 and 112:

• Functional requirements. These

- Page 113 and 114:

2.4.5 Safety assessment activitiesG

- Page 115 and 116:

equipment software and aircraft ins

- Page 117 and 118:

2.5.4 Factors associated with the i

- Page 119 and 120:

it is very difficult if not impossi

- Page 121 and 122:

applicable to highly-integrated or

- Page 123 and 124:

Ongoing developmentsA range of rese

- Page 125 and 126:

To conduct an effective fault tree

- Page 127 and 128:

According to this model, accidents

- Page 129 and 130:

3 FACTUAL INFORMATION: AIR DATA INE

- Page 131 and 132:

• inertial reference input/output

- Page 133 and 134:

3.3 Examination of data-spike patte

- Page 135 and 136:

Figure 38: ARINC 429 word for an AO

- Page 137 and 138:

3.3.4 Data-spike patterns for the 7

- Page 139 and 140:

Figure 43: Qualitative correlation

- Page 141 and 142:

etween the values of any of the fou

- Page 143 and 144:

3.4.3 Calculating parameter valuesA

- Page 145 and 146:

3.4.5 Packaging the ARINC 429 wordT

- Page 147 and 148:

3.4.8 Transmitting data to other sy

- Page 149 and 150:

ARINC 429 packaging analysisThe ADI

- Page 151 and 152:

component configurations of differe

- Page 153 and 154:

manufacturer reported such BITE dat

- Page 155 and 156:

3.6 Potential trigger types3.6.1 Ba

- Page 157 and 158:

such as liquids or small loose frag

- Page 159 and 160:

wires). The electric 144 field stre

- Page 161 and 162:

Although the investigation could no

- Page 163 and 164:

3.6.6 Single event effectsBackgroun

- Page 165 and 166:

until a few years ago, were not dir

- Page 167 and 168:

Unit testingIn 2005, as part of the

- Page 169 and 170:

that involved a NAV IR and/or NAV A

- Page 171 and 172:

EMI from other aircraft systems (su

- Page 173 and 174:

from ADIRU 1 was not correctly reco

- Page 175 and 176:

• Detected failure. Any failure w

- Page 177 and 178:

The ADIRU manufacturer’s analysis

- Page 179 and 180:

the aircraft and ADIRU manufacturer

- Page 181 and 182:

4 FACTUAL INFORMATION: CABIN SAFETY

- Page 183 and 184:

Summary details of the cabin crew

- Page 185 and 186:

section, and the ninth flight atten

- Page 187 and 188:

Table 29: Significant cabin communi

- Page 189 and 190:

Figure 48: Example of damage to the

- Page 191 and 192:

4.3.2 Seat belt examinationsSix pas

- Page 193 and 194:

The flight crew’s procedures requ

- Page 195 and 196:

takeoff, landing or when the seat-b

- Page 197 and 198:

Table 31: Levels of injuryInjury le

- Page 199 and 200:

4.6.4 Injuries to seated occupants

- Page 201 and 202:

The percentage of occupants who wer

- Page 203 and 204:

Statistical analyses 197 were done

- Page 205 and 206:

passengers reported that they had h

- Page 207 and 208:

that seat belts should be worn only

- Page 209:

4.8.2 Handholds in the cabinThe FAA

- Page 212 and 213:

Figure 53: Overview of the 7 Octobe

- Page 214 and 215:

process needs to ensure that there

- Page 216 and 217:

and determine whether they could le

- Page 218 and 219: useful in this case. If the EFCS sp

- Page 220 and 221: 5.3.2 Risk associated with the fail

- Page 222 and 223: • All three events occurred in a

- Page 224 and 225: place. Although aviation manufactur

- Page 226 and 227: equiring cabin crew to enforce the

- Page 228 and 229: With the information available to t

- Page 230 and 231: ADIRU 1 affected the operation of a

- Page 233 and 234: 6 FINDINGSFrom the evidence availab

- Page 235: • As of April 2010, the LTN-101 a

- Page 238 and 239: did not illuminate. The new OEB (A3

- Page 240 and 241: modifications were made to its guid

- Page 242 and 243: this advice. At the time of the fir

- Page 245 and 246: APPENDIX A: VERTICAL ACCELERATIONST

- Page 247 and 248: APPENDIX B: FLIGHT RECORDER INFORMA

- Page 249 and 250: APPENDIX C: POST-FLIGHT REPORTThe f

- Page 251 and 252: - 231 -

- Page 253 and 254: - 233 -

- Page 255 and 256: APPENDIX D: OTHER DATA-SPIKE OCCURR

- Page 257 and 258: Occurrence on 27 December 2008Overv

- Page 259 and 260: Figure D2: FDR data for the 27 Dece

- Page 261 and 262: ADIRU informationADIRU 1 was the sa

- Page 263 and 264: APPENDIX E: ADIRU TESTINGTest plan

- Page 265 and 266: Visual inspectionsExternal visual i

- Page 267: (ADR) output databuses. Loading on

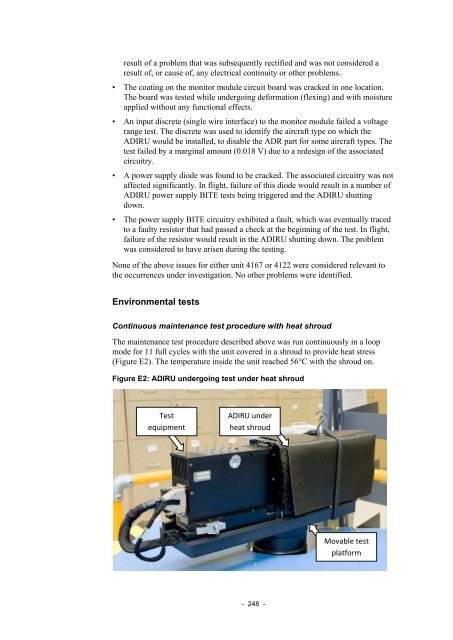

- Page 271 and 272: dwells (sustained testing at a fixe

- Page 273 and 274: APPENDIX F: AIRCRAFT LEVEL TESTINGI

- Page 275 and 276: APPENDIX G: ELECTROMAGNETIC RADIATI

- Page 277 and 278: cannot be ‘decoded’ by the rece

- Page 279 and 280: APPENDIX H: SINGLE EVENT EFFECTSNot

- Page 281 and 282: Factors affecting SEE exposureAn ai

- Page 283 and 284: portions of memory are constantly b

- Page 285: Depending on the form of EDAC, sing

- Page 288 and 289: • crew actions: the passenger’s

- Page 290 and 291: The questionnaire respondents were

- Page 292 and 293: was centred across the passenger’

- Page 294 and 295: Previous occurrencesThe seat belt m

- Page 296 and 297: Australian turbulence eventsThe mos

- Page 299 and 300: APPENDIX L: SEAT BELT USE IN ROAD V

- Page 301: Table L1: Recent seat belt use rate

- Page 304 and 305: US Federal Aviation AdministrationT

- Page 307 and 308: APPENDIX N: SOURCES AND SUBMISSIONS

- Page 309 and 310: Hanson, RJ 1987, Conducted electrom

- Page 311 and 312: Tvaryanas, AP 2003, ‘Epidemiology

- Page 313: In-flight upset - 154 km west of Le