Liebert Challenger 3000

Liebert Challenger™ 3000 Operation & Maintenance Manual - DCES

Liebert Challenger™ 3000 Operation & Maintenance Manual - DCES

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

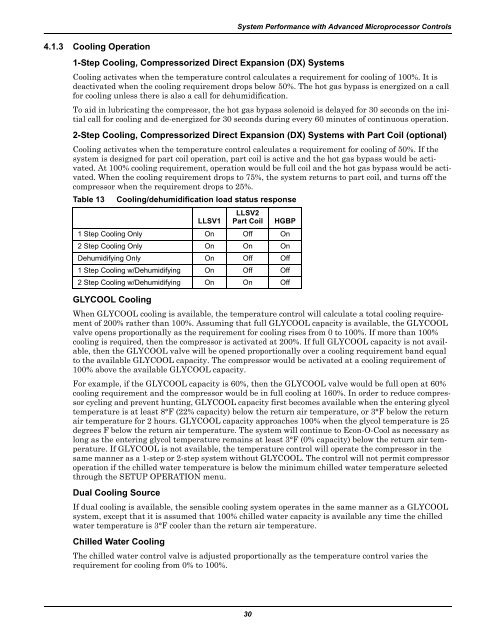

4.1.3 Cooling OperationSystem Performance with Advanced Microprocessor Controls1-Step Cooling, Compressorized Direct Expansion (DX) SystemsCooling activates when the temperature control calculates a requirement for cooling of 100%. It isdeactivated when the cooling requirement drops below 50%. The hot gas bypass is energized on a callfor cooling unless there is also a call for dehumidification.To aid in lubricating the compressor, the hot gas bypass solenoid is delayed for 30 seconds on the initialcall for cooling and de-energized for 30 seconds during every 60 minutes of continuous operation.2-Step Cooling, Compressorized Direct Expansion (DX) Systems with Part Coil (optional)Cooling activates when the temperature control calculates a requirement for cooling of 50%. If thesystem is designed for part coil operation, part coil is active and the hot gas bypass would be activated.At 100% cooling requirement, operation would be full coil and the hot gas bypass would be activated.When the cooling requirement drops to 75%, the system returns to part coil, and turns off thecompressor when the requirement drops to 25%.Table 13GLYCOOL CoolingCooling/dehumidification load status responseWhen GLYCOOL cooling is available, the temperature control will calculate a total cooling requirementof 200% rather than 100%. Assuming that full GLYCOOL capacity is available, the GLYCOOLvalve opens proportionally as the requirement for cooling rises from 0 to 100%. If more than 100%cooling is required, then the compressor is activated at 200%. If full GLYCOOL capacity is not available,then the GLYCOOL valve will be opened proportionally over a cooling requirement band equalto the available GLYCOOL capacity. The compressor would be activated at a cooling requirement of100% above the available GLYCOOL capacity.For example, if the GLYCOOL capacity is 60%, then the GLYCOOL valve would be full open at 60%cooling requirement and the compressor would be in full cooling at 160%. In order to reduce compressorcycling and prevent hunting, GLYCOOL capacity first becomes available when the entering glycoltemperature is at least 8°F (22% capacity) below the return air temperature, or 3°F below the returnair temperature for 2 hours. GLYCOOL capacity approaches 100% when the glycol temperature is 25degrees F below the return air temperature. The system will continue to Econ-O-Cool as necessary aslong as the entering glycol temperature remains at least 3°F (0% capacity) below the return air temperature.If GLYCOOL is not available, the temperature control will operate the compressor in thesame manner as a 1-step or 2-step system without GLYCOOL. The control will not permit compressoroperation if the chilled water temperature is below the minimum chilled water temperature selectedthrough the SETUP OPERATION menu.Dual Cooling SourceIf dual cooling is available, the sensible cooling system operates in the same manner as a GLYCOOLsystem, except that it is assumed that 100% chilled water capacity is available any time the chilledwater temperature is 3°F cooler than the return air temperature.Chilled Water CoolingLLSV1LLSV2Part CoilHGBP1 Step Cooling Only On Off On2 Step Cooling Only On On OnDehumidifying Only On Off Off1 Step Cooling w/Dehumidifying On Off Off2 Step Cooling w/Dehumidifying On On OffThe chilled water control valve is adjusted proportionally as the temperature control varies therequirement for cooling from 0% to 100%.30