SPECIFICATIONS

Tender Documents.pdf - Northern Rockies Regional Municipality

Tender Documents.pdf - Northern Rockies Regional Municipality

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

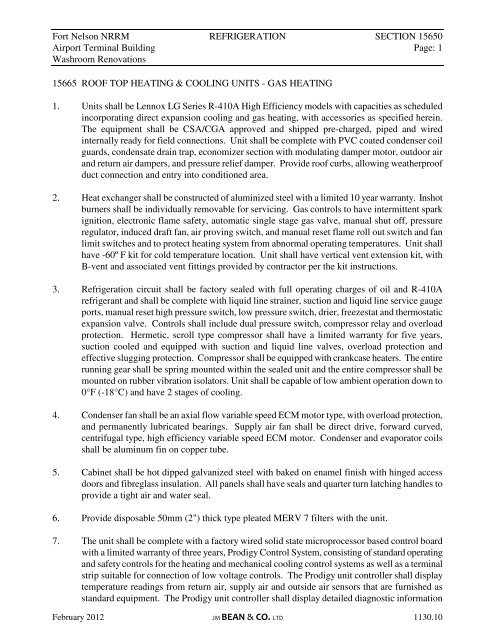

Fort Nelson NRRM REFRIGERATION SECTION 15650<br />

Airport Terminal Building Page: 1<br />

Washroom Renovations<br />

15665 ROOF TOP HEATING & COOLING UNITS - GAS HEATING<br />

1. Units shall be Lennox LG Series R-410A High Efficiency models with capacities as scheduled<br />

incorporating direct expansion cooling and gas heating, with accessories as specified herein.<br />

The equipment shall be CSA/CGA approved and shipped pre-charged, piped and wired<br />

internally ready for field connections. Unit shall be complete with PVC coated condenser coil<br />

guards, condensate drain trap, economizer section with modulating damper motor, outdoor air<br />

and return air dampers, and pressure relief damper. Provide roof curbs, allowing weatherproof<br />

duct connection and entry into conditioned area.<br />

2. Heat exchanger shall be constructed of aluminized steel with a limited 10 year warranty. Inshot<br />

burners shall be individually removable for servicing. Gas controls to have intermittent spark<br />

ignition, electronic flame safety, automatic single stage gas valve, manual shut off, pressure<br />

regulator, induced draft fan, air proving switch, and manual reset flame roll out switch and fan<br />

limit switches and to protect heating system from abnormal operating temperatures. Unit shall<br />

have -60º F kit for cold temperature location. Unit shall have vertical vent extension kit, with<br />

B-vent and associated vent fittings provided by contractor per the kit instructions.<br />

3. Refrigeration circuit shall be factory sealed with full operating charges of oil and R-410A<br />

refrigerant and shall be complete with liquid line strainer, suction and liquid line service gauge<br />

ports, manual reset high pressure switch, low pressure switch, drier, freezestat and thermostatic<br />

expansion valve. Controls shall include dual pressure switch, compressor relay and overload<br />

protection. Hermetic, scroll type compressor shall have a limited warranty for five years,<br />

suction cooled and equipped with suction and liquid line valves, overload protection and<br />

effective slugging protection. Compressor shall be equipped with crankcase heaters. The entire<br />

running gear shall be spring mounted within the sealed unit and the entire compressor shall be<br />

mounted on rubber vibration isolators. Unit shall be capable of low ambient operation down to<br />

0°F (-18°C) and have 2 stages of cooling.<br />

4. Condenser fan shall be an axial flow variable speed ECM motor type, with overload protection,<br />

and permanently lubricated bearings. Supply air fan shall be direct drive, forward curved,<br />

centrifugal type, high efficiency variable speed ECM motor. Condenser and evaporator coils<br />

shall be aluminum fin on copper tube.<br />

5. Cabinet shall be hot dipped galvanized steel with baked on enamel finish with hinged access<br />

doors and fibreglass insulation. All panels shall have seals and quarter turn latching handles to<br />

provide a tight air and water seal.<br />

6. Provide disposable 50mm (2") thick type pleated MERV 7 filters with the unit.<br />

7. The unit shall be complete with a factory wired solid state microprocessor based control board<br />

with a limited warranty of three years, Prodigy Control System, consisting of standard operating<br />

and safety controls for the heating and mechanical cooling control systems as well as a terminal<br />

strip suitable for connection of low voltage controls. The Prodigy unit controller shall display<br />

temperature readings from return air, supply air and outside air sensors that are furnished as<br />

standard equipment. The Prodigy unit controller shall display detailed diagnostic information<br />

February 2012 JM BEAN & CO. LTD 1130.10