75 years of Egokiefer: Tradition and Innovation

75 years of Egokiefer: Tradition and Innovation

75 years of Egokiefer: Tradition and Innovation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

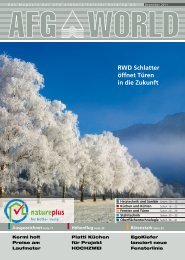

Surface Technology<br />

State-<strong>of</strong>-the-art screen basket production line covering more than 18,000 m 2 in the STI Surface Center in Sternenfels-Diefenbach, Germany.<br />

STI | Hartchrom with<br />

state-<strong>of</strong>-the-art infrastructure<br />

STI | Hartchrom is successfully defending its leading market position in the coating <strong>of</strong> parts<br />

from the paper industry. With the continuous development <strong>of</strong> new technologies <strong>and</strong> the usage<br />

<strong>of</strong> highly automated finishing lines, STI | Hartchrom specifically optimises solutions to suit<br />

the needs <strong>of</strong> its customers <strong>and</strong> their industry.<br />

STI | Hartchrom finishing technology was developed to meet<br />

the commercial performance requirements on parts such as<br />

cylinders, screen baskets, rolls <strong>and</strong> blades to the highest<br />

quality. The objective <strong>and</strong> purpose is increased corrosion resistance,<br />

excellent anti-adhesion properties, greater resistance<br />

to temperature effects <strong>and</strong> mechanical wear. As a result,<br />

system availability is increased <strong>and</strong> life cycle costs can be reduced.<br />

The precision, functionality <strong>and</strong> quality <strong>of</strong> the coating<br />

are key success factors for this dem<strong>and</strong>ing industry.<br />

High-end solutions<br />

Resistance to wear <strong>and</strong> impacts, defined slot widths, the possibility<br />

<strong>of</strong> re-coating, compliance with minimum layer thicknesses<br />

as well as short delivery times are also required for<br />

screen baskets for processing waste in the paper industry.<br />

The added value for customers is produced by high-end electropolishing<br />

<strong>and</strong> chromium plating processes, a special plant<br />

control system, state-<strong>of</strong>-the-art infrastructure <strong>and</strong> specialised<br />

41<br />

jig <strong>and</strong> fixture manufacture. Individual specifications are<br />

manufactured in reproducible quality with exact control. The<br />

speed <strong>of</strong> reaction <strong>of</strong> the staff also ensures maximum cost-<br />

effectiveness <strong>and</strong> adaptation to the situation on the market<br />

at any time, <strong>and</strong> that with very short order processing times.<br />

If necessary, STI | Hartchrom provides an «express service».<br />

STI Surface Center in Germany<br />

STI | Hartchrom <strong>and</strong> its subsidiaries are continuously working<br />

on providing advantages for the customer with the surface<br />

finish. Due to customer proximity, know-how, a willingness<br />

to innovate <strong>and</strong> its infrastructure, STI | Hartchrom creates<br />

maximum customer benefit. The STI Surface Center in<br />

Sternen fels-Diefenbach in Germany is equipped with the latest<br />

generation coating plant for very high requirements. The<br />

screen basket production line is the most modern <strong>and</strong> largest<br />

in Europe – chromium plating <strong>and</strong> electropolishing facilities<br />

are available in an area covering more than 18,000 m 2 . «