Specifiers Journal 2016

Specifiers Journal 2016

Specifiers Journal 2016

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Prefabricated three dimensional façade design and<br />

construction using prefabricated precast concrete<br />

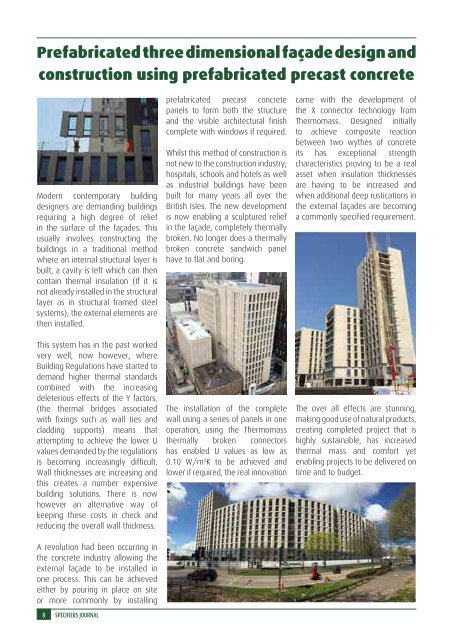

Modern contemporary building<br />

designers are demanding buildings<br />

requiring a high degree of relief<br />

in the surface of the façades. This<br />

usually involves constructing the<br />

buildings in a traditional method<br />

where an internal structural layer is<br />

built, a cavity is left which can then<br />

contain thermal insulation (If it is<br />

not already installed in the structural<br />

layer as in structural framed steel<br />

systems); the external elements are<br />

then installed.<br />

This system has in the past worked<br />

very well, now however, where<br />

Building Regulations have started to<br />

demand higher thermal standards<br />

combined with the increasing<br />

deleterious effects of the Y factors,<br />

(the thermal bridges associated<br />

with fixings such as wall ties and<br />

cladding supports) means that<br />

attempting to achieve the lower U<br />

values demanded by the regulations<br />

is becoming increasingly difficult.<br />

Wall thicknesses are increasing and<br />

this creates a number expensive<br />

building solutions. There is now<br />

however an alternative way of<br />

keeping these costs in check and<br />

reducing the overall wall thickness.<br />

A revolution had been occurring in<br />

the concrete industry allowing the<br />

external façade to be installed in<br />

one process. This can be achieved<br />

either by pouring in place on site<br />

or more commonly by installing<br />

8 SPECIFIERS JOURNAL<br />

prefabricated precast concrete<br />

panels to form both the structure<br />

and the visible architectural finish<br />

complete with windows if required.<br />

Whilst this method of construction is<br />

not new to the construction industry;<br />

hospitals, schools and hotels as well<br />

as industrial buildings have been<br />

built for many years all over the<br />

British Isles. The new development<br />

is now enabling a sculptured relief<br />

in the façade, completely thermally<br />

broken. No longer does a thermally<br />

broken concrete sandwich panel<br />

have to flat and boring.<br />

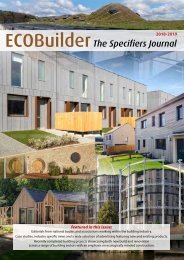

The installation of the complete<br />

wall using a series of panels in one<br />

operation, using the Thermomass<br />

thermally broken connectors<br />

has enabled U values as low as<br />

0.10 W/m 2 K to be achieved and<br />

lower if required, the real innovation<br />

came with the development of<br />

the X connector technology from<br />

Thermomass. Designed initially<br />

to achieve composite reaction<br />

between two wythes of concrete<br />

its has exceptional strength<br />

characteristics proving to be a real<br />

asset when insulation thicknesses<br />

are having to be increased and<br />

when additional deep rustications in<br />

the external façades are becoming<br />

a commonly specified requirement.<br />

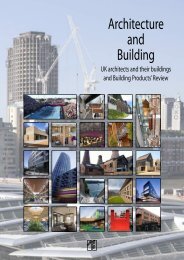

The over all effects are stunning,<br />

making good use of natural products,<br />

creating completed project that is<br />

highly sustainable, has increased<br />

thermal mass and comfort yet<br />

enabling projects to be delivered on<br />

time and to budget.