July August hi-res with ads

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

50 MACHINERY UPDATE JULY/AUGUST 2018 www.mac<strong>hi</strong>neryupdate.co.uk<br />

Feature: Automation, robotics and vision<br />

Mac<strong>hi</strong>ne vision is<br />

a great way to ‘see’<br />

defects in produce<br />

Many parameters and<br />

defects need to be<br />

considered in grading<br />

fruit and vegetables,<br />

especially when<br />

automating the inspection process.<br />

These include discolouration,<br />

ripeness, size, shape, bruising,<br />

mould, pests and diseases.<br />

Colour imaging, 3D imaging and<br />

image processing are important in<br />

measuring external characteristics<br />

of the produce such as colour,<br />

size and shape, but NIR imaging<br />

and the newer technique of<br />

hyperspectral imaging can be used<br />

to identify sub-surface defects<br />

such as bruising or diseases at an<br />

early stage before they manifest<br />

themselves on the surface, says<br />

Rob Webb of Stemmer Imaging.<br />

TARGET COLOUR RANGES<br />

High-end supermarkets favour<br />

produce <strong>with</strong> target colour ranges/<br />

shades and are willing to pay more<br />

for it. Line scan colour imaging,<br />

where an image is built up line<br />

by line as the produce passes in<br />

front of the camera, can help to<br />

automatically detect the produce’s<br />

colour and sort it at very <strong>hi</strong>gh<br />

speeds. Colour measurement<br />

can also be used in ripeness<br />

assessment. Supermarkets also<br />

set size requirements and by only<br />

harvesting at the right times,<br />

farmers can ensure that they have<br />

the <strong>hi</strong>ghest yield. 3D laser scanning<br />

of produce in the field helps locate<br />

the position and size of the produce<br />

to determine what should be picked<br />

(and when), passing the location<br />

of each acceptable item onto an<br />

automated robotic picking system.<br />

Separating ‘misshapen’ fruit and<br />

vegetables is also important.<br />

All produce has some natural<br />

variation in shape and the vision<br />

system needs to take t<strong>hi</strong>s into<br />

account <strong>with</strong> its grading process.<br />

Stemmer’s Common Vision Blox<br />

image processing software has<br />

a versatile pattern recognition<br />

tool developed from <strong>res</strong>earch into<br />

artificial intelligence that can<br />

Detecting a<br />

fruit defect<br />

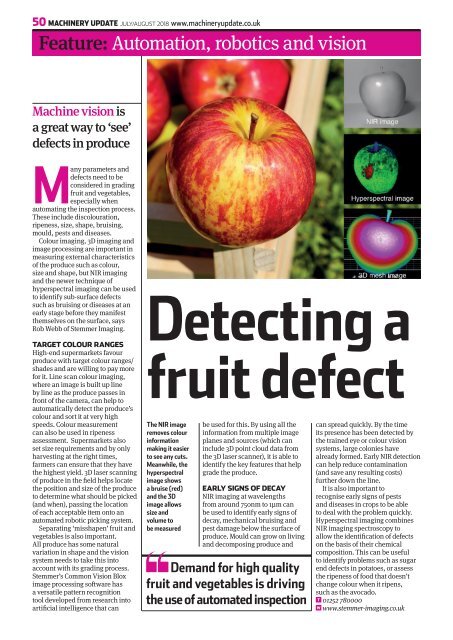

The NIR image<br />

removes colour<br />

information<br />

making it easier<br />

to see any cuts.<br />

Meanw<strong>hi</strong>le, the<br />

hyperspectral<br />

image shows<br />

a bruise (red)<br />

and the 3D<br />

image allows<br />

size and<br />

volume to<br />

be measured<br />

be used for t<strong>hi</strong>s. By using all the<br />

information from multiple image<br />

planes and sources (w<strong>hi</strong>ch can<br />

include 3D point cloud data from<br />

the 3D laser scanner), it is able to<br />

identify the key featu<strong>res</strong> that help<br />

grade the produce.<br />

EARLY SIGNS OF DECAY<br />

NIR imaging at wavelengths<br />

from around 750nm to 1µm can<br />

be used to identify early signs of<br />

decay, mechanical bruising and<br />

pest damage below the surface of<br />

produce. Mould can grow on living<br />

and decomposing produce and<br />

Demand for <strong>hi</strong>gh quality<br />

fruit and vegetables is driving<br />

the use of automated inspection<br />

can spread quickly. By the time<br />

its p<strong>res</strong>ence has been detected by<br />

the trained eye or colour vision<br />

systems, large colonies have<br />

already formed. Early NIR detection<br />

can help reduce contamination<br />

(and save any <strong>res</strong>ulting costs)<br />

further down the line.<br />

It is also important to<br />

recognise early signs of pests<br />

and diseases in crops to be able<br />

to deal <strong>with</strong> the problem quickly.<br />

Hyperspectral imaging combines<br />

NIR imaging spectroscopy to<br />

allow the identification of defects<br />

on the basis of their chemical<br />

composition. T<strong>hi</strong>s can be useful<br />

to identify problems such as sugar<br />

end defects in potatoes, or assess<br />

the ripeness of food that doesn’t<br />

change colour when it ripens,<br />

such as the avocado.<br />

T 01252 780000<br />

W www.stemmer-imaging.co.uk