SSG No 20 - Shipgaz

SSG No 20 - Shipgaz

SSG No 20 - Shipgaz

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

technical news<br />

Editor: Robert Hermansson ~ Phone: +46 40 15 61 44 ~ E-mail: robert@shipgaz.com<br />

New temperature control valve<br />

Amot has recently introduced the improved<br />

version of the G temperature control valve.<br />

The updated G valve gives optimal matching<br />

to the installation piping and is well<br />

suited for both mixing and diverting applications.<br />

It is mainly used for fluid temperature<br />

control in large diesel and gas engines<br />

for purposes such as oil temperature control,<br />

jacket water cooling, charge air temperature<br />

control etc. The valve has a very low<br />

weight and offers rapid and accurate regulations<br />

of temperatures up to 100° C with<br />

flow rates of maximum 3,000 cbm/hr.<br />

Among the accessories is the new<br />

8071/2D PID controller, that incorporates<br />

temperature dead band, remote alarms and<br />

logic outputs to drive 25A solid state relays<br />

and the advanced 8060 temperature sensor.<br />

For more information please contact:<br />

Paula Halpin, Tel. +44 (0)1737 222 552<br />

E-mail: info@amot.com<br />

www.amot.com<br />

Solvent-free coating<br />

for potable water<br />

Water must be clean, safe to drink and<br />

without surprising taste or smell. Hempel’s<br />

new Hempadur 3556 coating is free of<br />

solvents and benzyl alcohol, thus has no<br />

chemical taste or odour. It provides excellent<br />

corrosion resistance and cathodic protection<br />

and needs minimal maintenance<br />

for up to 25 years. Most of the solvent-free<br />

epoxy coatings on the market require special<br />

paint application equipment or heating.<br />

Hempadur 3556 is formulated for<br />

easy application and there is no need for<br />

heating or thinning even when the paint is<br />

applied at temperatures as low as 10°C.<br />

Hempadur 3556 is a two-component<br />

polyamine adduct cured epoxy coating. It is<br />

approved by Great Britain’s Water Research<br />

Centre, WRAS, according to BS 69<strong>20</strong> for<br />

potable water up to 23°C, by <strong>No</strong>rway’s<br />

Folkehelseinstituttet for use in offshore<br />

potable water tanks and is currently undergoing<br />

US testing to meet NSF standard 61.<br />

For more information please contact:<br />

Michael Aamodt, tel. +45 4527 3673<br />

Mob. +45 2427 0931<br />

E-mail: mia@dk.hempel.com<br />

www.hempel.com<br />

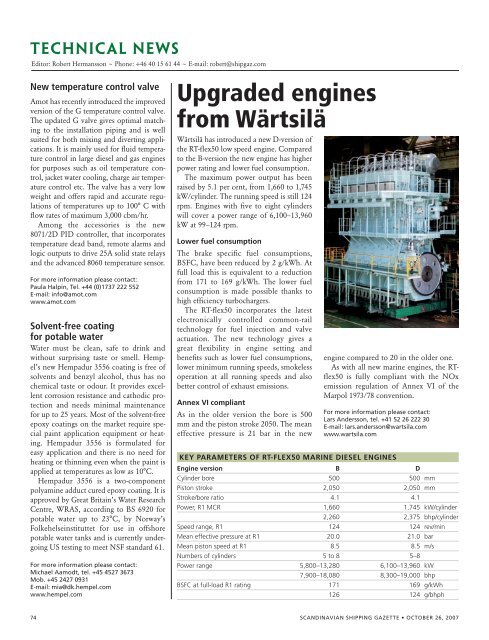

Upgraded engines<br />

from Wärtsilä<br />

Wärtsilä has introduced a new D-version of<br />

the RT-flex50 low speed engine. Compared<br />

to the B-version the new engine has higher<br />

power rating and lower fuel consumption.<br />

The maximum power output has been<br />

raised by 5.1 per cent, from 1,660 to 1,745<br />

kW/cylinder. The running speed is still 124<br />

rpm. Engines with five to eight cylinders<br />

will cover a power range of 6,100–13,960<br />

kW at 99–124 rpm.<br />

Lower fuel consumption<br />

The brake specific fuel consumptions,<br />

BSFC, have been reduced by 2 g/kWh. At<br />

full load this is equivalent to a reduction<br />

from 171 to 169 g/kWh. The lower fuel<br />

consumption is made possible thanks to<br />

high efficiency turbochargers.<br />

The RT-flex50 incorporates the latest<br />

electronically controlled common-rail<br />

technology for fuel injection and valve<br />

actuation. The new technology gives a<br />

great flexibility in engine setting and<br />

benefits such as lower fuel consumptions,<br />

lower minimum running speeds, smokeless<br />

operation at all running speeds and also<br />

better control of exhaust emissions.<br />

Annex VI compliant<br />

As in the older version the bore is 500<br />

mm and the piston stroke <strong>20</strong>50. The mean<br />

effective pressure is 21 bar in the new<br />

engine compared to <strong>20</strong> in the older one.<br />

As with all new marine engines, the RTflex50<br />

is fully compliant with the NOx<br />

emission regulation of Annex VI of the<br />

Marpol 1973/78 convention.<br />

For more information please contact:<br />

Lars Andersson, tel. +41 52 26 222 30<br />

E-mail: lars.andersson@wartsila.com<br />

www.wartsila.com<br />

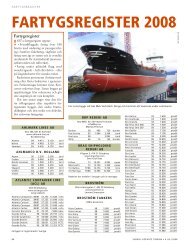

Key pArAmeters of rt-fLex50 mArIne dIeseL engInes<br />

engine version B d<br />

Cylinder bore 500 500 mm<br />

Piston stroke 2,050 2,050 mm<br />

Stroke/bore ratio 4.1 4.1<br />

Power, R1 MCR 1,660 1,745 kW/cylinder<br />

2,260 2,375 bhp/cylinder<br />

Speed range, R1 124 124 rev/min<br />

Mean effective pressure at R1 <strong>20</strong>.0 21.0 bar<br />

Mean piston speed at R1 8.5 8.5 m/s<br />

Numbers of cylinders 5 to 8 5–8<br />

Power range 5,800–13,280 6,100–13,960 kW<br />

7,900–18,080 8,300–19,000 bhp<br />

BSFC at full-load R1 rating 171 169 g/kWh<br />

126 124 g/bhph<br />

74 SCANDINAVIAN SHIPPING GAZETTE • OCTOBER 26, <strong>20</strong>07