WIA_ISSUE2_2023

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BIG PICTURE<br />

members. It was also said to be the<br />

first project in the US to use an efficient<br />

hybrid wood and glass enclosure to<br />

envelop two existing structures.<br />

Parallam is made by bonding together<br />

“thin strands of wood” like southern<br />

pine, yellow poplar, Douglas fir or<br />

western hemlock that are “typically<br />

4-8ft-long”, and offers good connection<br />

strength and ductility due to its<br />

uniformity, not prone to splitting failures<br />

at connections like sawn timber or<br />

glue-laminated timber. 1 It also has<br />

strong insect resistance.<br />

The custom timber structure supports<br />

a 650ft-long curved cable-suspended<br />

glazed facade. Each of the 18 massive<br />

elliptically-turned parallam columns<br />

are tipped with a custom-shaped<br />

350lb, or approximately 159kg,<br />

casting and tilted at 4° from vertical<br />

axis. The 50-60ft-high columns not<br />

only support the suspended array of<br />

parallam glazing members, but also a<br />

500ft-long steel roof structure with 90ft<br />

cantilever. According to a statement<br />

by the architect, the parallam columns<br />

“have an elliptical shape to reduce their<br />

visual impact and are spaced 36ft apart<br />

so that the building still feels quite<br />

transparent”. 2<br />

3<br />

Although the timber-backed glass<br />

facade supporting a steel roof was a<br />

complex design, the decision to use<br />

wood was an easy one. “Like most arts<br />

projects, especially non-profits like the<br />

Arena Stage, the budget was very tight,”<br />

said Michael Heeney, a key member<br />

of the architectural team, Bing Thom<br />

Architects of Vancouver, Canada (now<br />

Revery Architecture). “We did not have<br />

money for finishes, so the structure had<br />

to be beautiful, and wood made perfect<br />

sense. Yet in the end, wood ended up<br />

doing triple duty. We used it to hold up<br />

the roof; we also used it to hold up the<br />

glass; and it provided the final finish for<br />

the space. Wood was very cost-effective<br />

in all three respects.” <strong>WIA</strong><br />

References<br />

1. StructureCraft. Parallel strand lumber. <br />

2. Arena Stage. Architect’s statement. <br />

3. WoodWorks. Arena Stage – Innovative hybrid<br />

structure in DC. <br />

4 5<br />

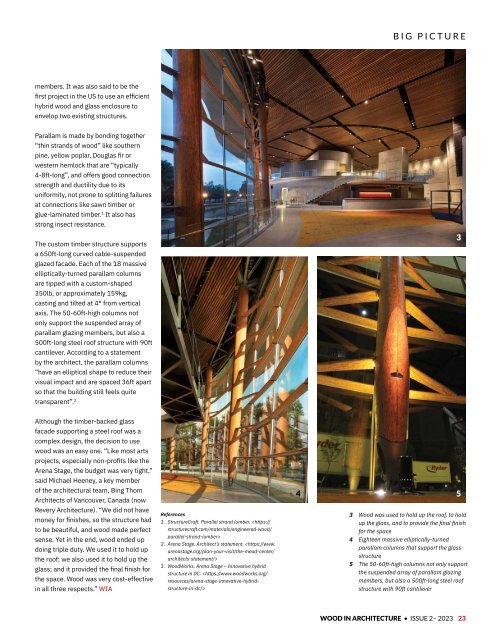

3 Wood was used to hold up the roof, to hold<br />

up the glass, and to provide the final finish<br />

for the space<br />

4 Eighteen massive elliptically-turned<br />

parallam columns that support the glass<br />

structure<br />

5 The 50-60ft-high columns not only support<br />

the suspended array of parallam glazing<br />

members, but also a 500ft-long steel roof<br />

structure with 90ft cantilever<br />

WOOD IN ARCHITECTURE • ISSUE 2– <strong>2023</strong> 23