WIA_ISSUE2_2023

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DESIGN<br />

1<br />

2<br />

LASER AND SURFACE<br />

TECHNOLOGY<br />

With a speed of up to 3m/min and<br />

a dynamic ray system, SCM wood<br />

flooring machine is said to allow the<br />

operator to score carved surfaces,<br />

replicate wood grain and achieve<br />

geometrical and abstract patterns. It<br />

is also well-suited to machining fibre<br />

cement for walls and flooring, or for<br />

customising and veneering kitchen<br />

cabinet doors due to its laser engraving<br />

unit. Further, SCM’s sergiani 3d form<br />

3D laminating press provides relief<br />

marking before painting or polyvinyl<br />

chloride (PVC) plating on MDF panels.<br />

Hence, with its laser technology, one<br />

can veneer and customise materials<br />

such as Corian as part of a solid<br />

surface. The group’s sanding solutions<br />

can integrate with Superfici solutions<br />

for finishing, and others for panel<br />

pressing and veneering. <strong>WIA</strong><br />

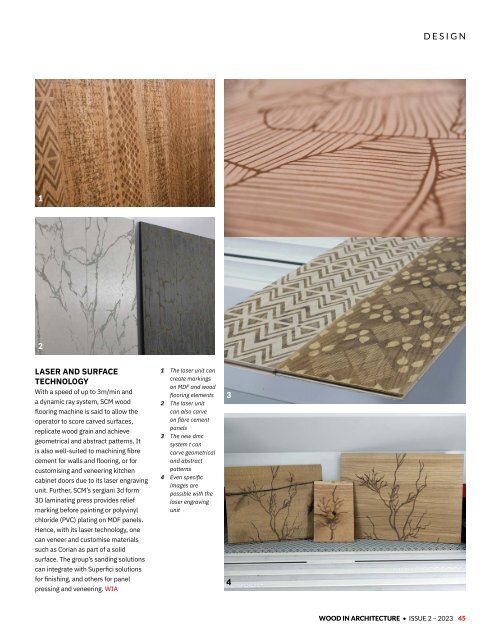

1 The laser unit can<br />

create markings<br />

on MDF and wood<br />

flooring elements<br />

2 The laser unit<br />

can also carve<br />

on fibre cement<br />

panels<br />

3 The new dmc<br />

system t can<br />

carve geometrical<br />

and abstract<br />

patterns<br />

4 Even specific<br />

images are<br />

possible with the<br />

laser engraving<br />

unit<br />

3<br />

4<br />

WOOD IN ARCHITECTURE • ISSUE 2 – <strong>2023</strong> 45