WIA_ISSUE2_2023

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FLOORING<br />

Head-end profiling<br />

of floorboards<br />

with Marinus<br />

Powermax<br />

Endmatcher<br />

The Marinus Powermax Endmatcher is designed<br />

for the head-end machining of tongue-andgrooves<br />

on floorboards, decking and cladding,<br />

able to produce fixed and variable lengths.<br />

Developed by Netherlands-based engineered<br />

wood processing machine manufacturer<br />

Marinus, the Powermax Endmatcher can cut<br />

to length, cut out defects, and do head-end<br />

profiling — all in a single pass of the wood panel<br />

through the machine.<br />

The machine is controlled on a user-friendly<br />

touch screen panel. Before the profiling takes<br />

place, the wood panel is brought to a stationary<br />

position, fixed sideways and clamped to an<br />

accurate reference surface above. This results<br />

in high profile accuracy, with no noticeable edge<br />

on the top of the boards when they are fitted<br />

together, according to Marinus. Furthermore,<br />

this clamping system, combined with two<br />

pre-cut aluminium backing blocks, prevents<br />

blow-outs and splintering. The mechanisms of<br />

the Endmatcher — for clamping, cutting, and<br />

profiling — are driven by Lenze servo motors,<br />

which are said to be suitable for applications<br />

that are high-performance and need precision,<br />

according to Lenze’s website.<br />

When feeding the wood panel into the<br />

Endmatcher, it is possible for the machine<br />

to cut out defects like knots or cracks. The<br />

operator must first mark out the defects using<br />

a luminescent crayon. After which, when the<br />

wood panel enters the machine, a sensor within<br />

it will detect and cut out the marked defects,<br />

including the crayon lines.<br />

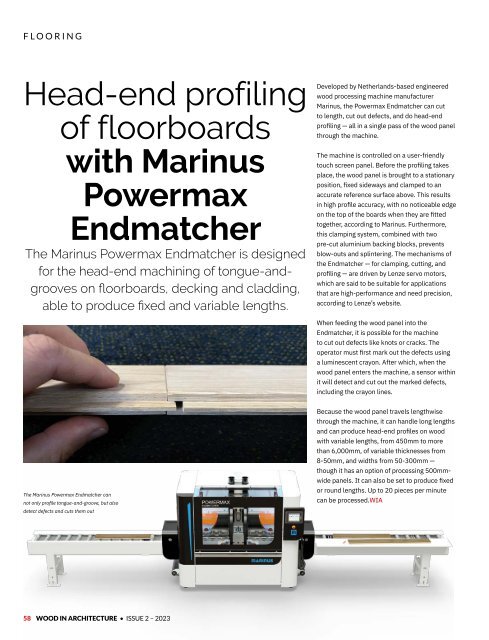

The Marinus Powermax Endmatcher can<br />

not only profile tongue-and-groove, but also<br />

detect defects and cuts them out<br />

Because the wood panel travels lengthwise<br />

through the machine, it can handle long lengths<br />

and can produce head-end profiles on wood<br />

with variable lengths, from 450mm to more<br />

than 6,000mm, of variable thicknesses from<br />

8-50mm, and widths from 50-300mm —<br />

though it has an option of processing 500mmwide<br />

panels. It can also be set to produce fixed<br />

or round lengths. Up to 20 pieces per minute<br />

can be processed.<strong>WIA</strong><br />

58 WOOD IN ARCHITECTURE • ISSUE 2 – <strong>2023</strong>