SERVICE MANUAL MR-G57N-T-NZ - B.d.t.

SERVICE MANUAL MR-G57N-T-NZ - B.d.t.

SERVICE MANUAL MR-G57N-T-NZ - B.d.t.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

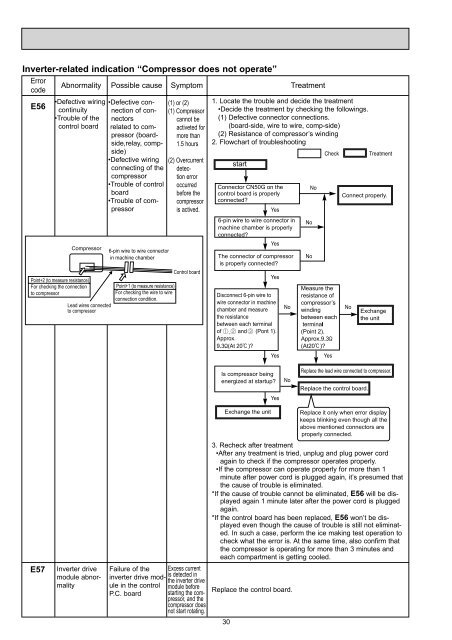

Inverter-related indication “Compressor does not operate”<br />

Error<br />

code<br />

Abnormality Possible cause Symptom Treatment<br />

E56<br />

•Defective wiring<br />

continuity<br />

•Trouble of the<br />

control board<br />

Compressor<br />

Point+2 (to measure resistance)<br />

For checking the connection<br />

to compressor<br />

E57<br />

Lead wires connected<br />

to compressor<br />

Inverter drive<br />

module abnormality<br />

•Defective connection<br />

of connectors<br />

related to compressor(boardside,relay,compside)<br />

•Defective wiring<br />

connecting of the<br />

compressor<br />

•Trouble of control<br />

board<br />

•Trouble of compressor<br />

6-pin wire to wire connector<br />

in machine chamber<br />

Point+1 (to measure resistance)<br />

For checking the wire to wire<br />

connection condition.<br />

(1) or (2)<br />

(1) Compressor<br />

cannot be<br />

activeted for<br />

more than<br />

1.5 hours<br />

(2) Overcurrent<br />

detection<br />

error<br />

occurred<br />

before the<br />

compressor<br />

is actived.<br />

Control board<br />

Failure of the Excess current<br />

inverter drive mod- is detected in<br />

the inverter drive<br />

ule in the control module before<br />

P.C. board<br />

starting the compressor,<br />

and the<br />

compressor does<br />

not start rotating.<br />

1. Locate the trouble and decide the treatment<br />

•Decide the treatment by checking the followings.<br />

(1) Defective connector connections.<br />

(board-side, wire to wire, comp-side)<br />

(2) Resistance of compressor’s winding<br />

2. Flowchart of troubleshooting<br />

3. Recheck after treatment<br />

•After any treatment is tried, unplug and plug power cord<br />

again to check if the compressor operates properly.<br />

•If the compressor can operate properly for more than 1<br />

minute after power cord is plugged again, it’s presumed that<br />

the cause of trouble is eliminated.<br />

*If the cause of trouble cannot be eliminated, E56 will be displayed<br />

again 1 minute later after the power cord is plugged<br />

again.<br />

*If the control board has been replaced, E56 won’t be displayed<br />

even though the cause of trouble is still not eliminated.<br />

In such a case, perform the ice making test operation to<br />

check what the error is. At the same time, also confirm that<br />

the compressor is operating for more than 3 minutes and<br />

each compartment is getting cooled.<br />

30<br />

start<br />

Connector CN50G on the<br />

control board is properly<br />

connected?<br />

6-pin wire to wire connector in<br />

machine chamber is properly<br />

connected?<br />

The connector of compressor<br />

is properly connected?<br />

Disconnect 6-pin wire to<br />

wire connector in machine<br />

chamber and measure<br />

the resistance<br />

between each terminal<br />

of and (Pont 1).<br />

Approx.<br />

Is compressor being<br />

energized at startup?<br />

Exchange the unit<br />

Yes<br />

Yes<br />

Yes<br />

No<br />

Check<br />

Yes Yes<br />

Yes<br />

No<br />

No<br />

Replace the control board.<br />

No<br />

No<br />

Connect properly.<br />

No<br />

Exchange<br />

the unit<br />

Replace the lead wire connected to compressor.<br />

Replace the control board.<br />

Treatment<br />

Replace it only when error display<br />

keeps blinking even though all the<br />

above mentioned connectors are<br />

properly connected.