SEC-400series - Shavo Technologies

SEC-400series - Shavo Technologies

SEC-400series - Shavo Technologies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

47<br />

ANALYSIS<br />

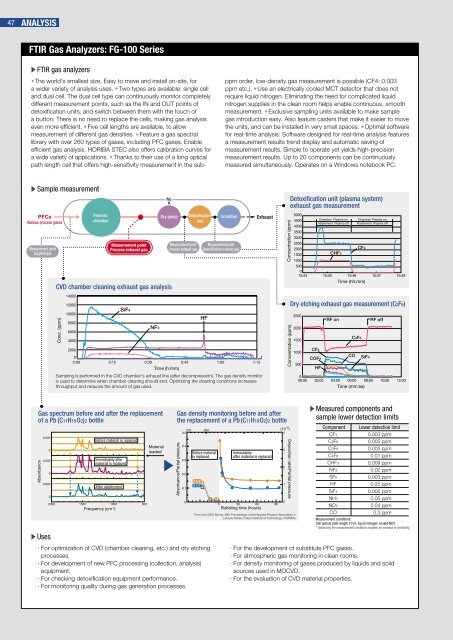

FTIR Gas Analyzers: FG-100 Series<br />

sFTIR gas analyzers<br />

sThe world's smallest size. Easy to move and install on-site, for<br />

a wider variety of analysis uses. sTwo types are available: single cell<br />

and dual cell. The dual cell type can continuously monitor completely<br />

different measurement points, such as the IN and OUT points of<br />

detoxification units, and switch between them with the touch of<br />

a button. There is no need to replace the cells, making gas analysis<br />

even more efficient. sFive cell lengths are available, to allow<br />

measurement of different gas densities. sFeature a gas spectral<br />

library with over 260 types of gases, including PFC gases. Enable<br />

efficient gas analysis. HORIBA STEC also offers calibration curves for<br />

a wide variety of applications. sThanks to their use of a long optical<br />

path length cell that offers high-sensitivity measurement in the sub-<br />

sSample measurement<br />

PFCs<br />

Various process gases<br />

Measurement point<br />

Supplied gas<br />

Process<br />

chamber<br />

Measurement point<br />

Process exhaust gas<br />

Gas spectrum before and after the replacement<br />

of a Pb (C11H19O2)2 bottle<br />

Absorbance<br />

0.005<br />

0<br />

0.005<br />

0<br />

0.005<br />

0<br />

2000<br />

N2<br />

Dry pump<br />

CVD chamber cleaning exhaust gas analysis<br />

Conc. (ppm)<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

4000<br />

2000<br />

SiF4<br />

Measurement point<br />

Process exhaust gas<br />

Detoxification<br />

unit<br />

sUses<br />

· For optimization of CVD (chamber cleaning, etc.) and dry etching<br />

processes.<br />

· For development of new PFC processing (collection, analysis)<br />

equipment.<br />

· For checking detoxification equipment performance.<br />

· For monitoring quality during gas generation processes.<br />

ppm order, low-density gas measurement is possible (CF4: 0.003<br />

ppm etc.). sUse an electrically cooled MCT detector that does not<br />

require liquid nitrogen. Eliminating the need for complicated liquid<br />

nitrogen supplies in the clean room helps enable continuous, smooth<br />

measurement. sExclusive sampling units available to make sample<br />

gas introduction easy. Also feature casters that make it easier to move<br />

the units, and can be installed in very small spaces. sOptimal software<br />

for real-time analysis: Software designed for real-time analysis features<br />

a measurement results trend display and automatic saving of<br />

measurement results. Simple to operate yet yields high-precision<br />

measurement results. Up to 20 components can be continuously<br />

measured simultaneously. Operates on a Windows notebook PC.<br />

Scrubber<br />

0<br />

0:00<br />

0:15 0:30 0:45 1:00 1:15<br />

Time (h:mm)<br />

Sampling is performed in the CVD chamber's exhaust line (after decompression). The gas density monitor<br />

is used to determine when chamber cleaning should end. Optimizing the cleaning conditions increases<br />

throughput and reduces the amount of gas used.<br />

Before material is replaced<br />

Immediately after<br />

material is replaced<br />

After stabilization<br />

1500 1000 500<br />

Frequency (cm -1 )<br />

NF3<br />

Material<br />

loaded<br />

Exhaust<br />

Gas density monitoring before and after<br />

the replacement of a Pb (C11H19O2)2 bottle<br />

Absorbance/Partial pressure<br />

570 600<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0<br />

Measurement point<br />

Detoxification exhaust gas<br />

HF<br />

Before material<br />

is replaced<br />

Immediately<br />

after material is replaced<br />

(10<br />

4<br />

-5 )<br />

Deposition rate/Partial pressure<br />

0<br />

0<br />

30 60 90<br />

Bubbling time (hours)<br />

*From the 2002 Spring 49th Proceedings of the Applied Physics Association's<br />

Lecture Series (Tokyo Institute of Technology, HORIBA).<br />

3<br />

2<br />

1<br />

Concentration (ppm)<br />

Detoxification unit (plasma system)<br />

exhaust gas measurement<br />

Concentration (ppm)<br />

5000<br />

4500<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

Chamber: Plasma on<br />

Abatement: Plasma off<br />

CHF3<br />

Chamber: Plasma on<br />

Abatement: Plasma off<br />

1000<br />

500<br />

0<br />

15:44 15:45 15:46<br />

Time (hh:mm)<br />

15:47 15:48<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

CF4<br />

COF2<br />

RF on<br />

C2F6<br />

sMeasured components and<br />

sample lower detection limits<br />

· For the development of substitute PFC gases.<br />

· For atmospheric gas monitoring in clean rooms.<br />

· For density monitoring of gases produced by liquids and solid<br />

sources used in MOCVD.<br />

· For the evaluation of CVD material properties.<br />

HF<br />

CO<br />

CF4<br />

Dry etching exhaust gas measurement (C2F6)<br />

SiF4<br />

RF off<br />

0<br />

00:00 02:00 04:00 06:00 08:00 10:00 12:00<br />

Time (mm:ss)<br />

Component<br />

CF4<br />

C2F6<br />

C3F8<br />

C4F8<br />

CHF3<br />

NF3<br />

SF6<br />

HF<br />

SiF4<br />

NH3<br />

NO2<br />

CO<br />

Lower detection limit<br />

0.003 ppm<br />

0.005 ppm<br />

0.005 ppm<br />

0.01 ppm<br />

0.009 ppm<br />

0.02 ppm<br />

0.003 ppm<br />

0.25 ppm<br />

0.006 ppm<br />

0.05 ppm<br />

0.04 ppm<br />

0.3 ppm<br />

Measurement conditions:<br />

Cell optical path length 10 m, liquid nitrogen cooled MCT<br />

* Optimizing the measurement conditions enables an increase in sensitivity.