SEC-400series - Shavo Technologies

SEC-400series - Shavo Technologies

SEC-400series - Shavo Technologies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

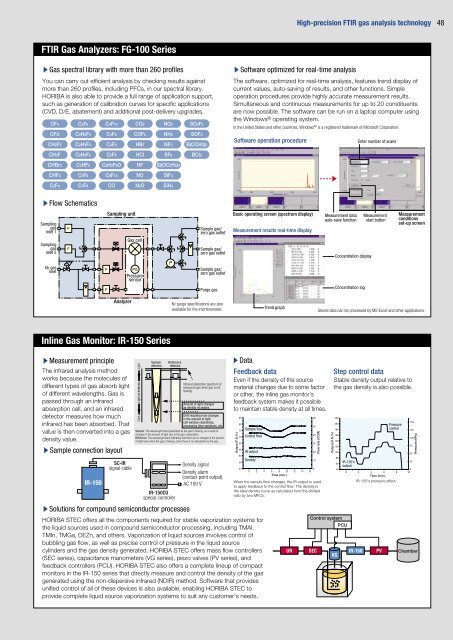

FTIR Gas Analyzers: FG-100 Series<br />

sGas spectral library with more than 260 profiles<br />

You can carry out efficient analysis by checking results against<br />

more than 260 profiles, including PFCs, in our spectral library.<br />

HORIBA is also able to provide a full range of application support,<br />

such as generation of calibration curves for specific applications<br />

(CVD, D/E, abatement) and additional post-delivery upgrades.<br />

CF4<br />

CF3l<br />

CH2F2<br />

CH3F<br />

CHBr3<br />

CHF3<br />

C2F4<br />

C2F6<br />

C2H2F4<br />

C2H3F3<br />

C2H4F2<br />

C2HF5<br />

C3F6<br />

C3F8<br />

sFlow Schematics<br />

Sampling<br />

gas<br />

inlet 1<br />

Sampling<br />

gas<br />

inlet 2<br />

N2 gas<br />

inlet<br />

Inline Gas Monitor: IR-150 Series<br />

sMeasurement principle<br />

The infrared analysis method<br />

works because the molecules of<br />

different types of gas absorb light<br />

of different wavelengths. Gas is<br />

passed through an infrared<br />

absorption cell, and an infrared<br />

detector measures how much<br />

infrared has been absorbed. That<br />

value is then converted into a gas<br />

density value.<br />

sSample connection layout<br />

IR-150<br />

C4F10<br />

C4F6<br />

C4F8<br />

C5F8<br />

C5H3F9O<br />

C8F18<br />

CO<br />

Sampling unit<br />

Analyzer<br />

SC-IR<br />

signal cable<br />

CO2<br />

COF2<br />

HBr<br />

HCl<br />

HF<br />

NO<br />

N2O<br />

Gas cell<br />

Pressure<br />

sensor<br />

Sample<br />

detector<br />

Reference<br />

detector<br />

IR-150CU<br />

special controller<br />

sSolutions for compound semiconductor processes<br />

Light<br />

Dark Light at detector<br />

Infrared absorption spectrum of<br />

measured gas when gas is not<br />

flowing.<br />

Amount of light changes<br />

as density increases.<br />

Drift resulting from changes<br />

in the amount of light,<br />

cell window cleanliness,<br />

processing time variations, etc.<br />

Sample: The wavelength band generated as the gas is flowing, as a result of<br />

changes in the amount of light due to the gas's absorption.<br />

Reference: The wavelength band indicating that there are no changes in the amount<br />

of light even when the gas is flowing, since there is no absorption by the gas.<br />

Density signal<br />

Density alarm<br />

(contact point output)<br />

AC 100 V<br />

The software, optimized for real-time analysis, features trend display of<br />

current values, auto-saving of results, and other functions. Simple<br />

operation procedures provide highly accurate measurement results.<br />

Simultaneous and continuous measurements for up to 20 constituents<br />

are now possible. The software can be run on a laptop computer using<br />

the Windows ® operating system.<br />

In the United States and other countries, Windows ® sSoftware optimized for real-time analysis<br />

is a registered trademark of Microsoft Corporation.<br />

sData<br />

HORIBA STEC offers all the components required for stable vaporization systems for<br />

the liquid sources used in compound semiconductor processing, including TMAI,<br />

TMIn, TMGa, DEZn, and others. Vaporization of liquid sources involves control of<br />

bubbling gas flow, as well as precise control of pressure in the liquid source<br />

cylinders and the gas density generated. HORIBA STEC offers mass flow controllers<br />

(<strong>SEC</strong> series), capacitance manometers (VG series), piezo valves (PV series), and<br />

feedback controllers (PCU). HORIBA STEC also offers a complete lineup of compact<br />

monitors in the IR-150 series that directly measure and control the density of the gas<br />

generated using the non-dispersive infrared (NDIR) method. Software that provides<br />

unified control of all of these devices is also available, enabling HORIBA STEC to<br />

provide complete liquid source vaporization systems to suit any customer's needs.<br />

NO2<br />

NH3<br />

NF3<br />

SF6<br />

Si(OC2H5)4<br />

SiF4<br />

SiH4<br />

SO2F2<br />

SOF2<br />

B(OCH3)3<br />

BCl3<br />

Sample gas/<br />

zero gas outlet<br />

Sample gas/<br />

zero gas outlet<br />

Sample gas/<br />

zero gas outlet<br />

Purge gas<br />

N2 purge specifications are also<br />

available for the interferometer.<br />

Software operation procedure<br />

Feedback data Step control data<br />

Even if the density of the source<br />

material changes due to some factor<br />

or other, the inline gas monitor's<br />

feedback system makes it possible<br />

to maintain stable density at all times.<br />

85<br />

60<br />

80<br />

75 Sample flow<br />

50<br />

70 Control flow<br />

40<br />

65<br />

30<br />

60<br />

55<br />

IR output<br />

20<br />

50<br />

Density<br />

10<br />

45<br />

0<br />

0 2 4 6 8 10 12 14 16<br />

Time (min.)<br />

Output (F.S.%)<br />

When the sample flow changes, the IR output is used<br />

to apply feedback to the control flow. The density is<br />

the ideal density curve as calculated from the divided<br />

ratio by two MFCs.<br />

Flow rate (CCM)<br />

220<br />

200<br />

Pressure<br />

150<br />

180<br />

160<br />

140<br />

control 125<br />

100<br />

120<br />

75<br />

100<br />

80<br />

50<br />

60 IR-150's<br />

output<br />

25<br />

40<br />

0<br />

0 2<br />

4<br />

6 8 10<br />

Time (min.)<br />

IR-150's pressure effect<br />

Output (F.S.%)<br />

Control system<br />

Stable density output relative to<br />

the gas density is also possible.<br />

PCU<br />

Enter number of scans<br />

Basic operating screen (spectrum display)<br />

Measurement results real-time display<br />

Measurement data<br />

auto-save function<br />

Measurement<br />

start button<br />

Measurement<br />

conditions<br />

set-up screen<br />

Trend graph<br />

High-precision FTIR gas analysis technology 48<br />

Concentration display<br />

Concentration log<br />

Stored data can be processed by MS-Excel and other applications.<br />

UR <strong>SEC</strong> IR-150 PV<br />

VG<br />

Pressure (kPa)<br />

Chamber