UNIVERSIT . . AT BONN Physikalisches Institut - Prof. Dr. Norbert ...

UNIVERSIT . . AT BONN Physikalisches Institut - Prof. Dr. Norbert ...

UNIVERSIT . . AT BONN Physikalisches Institut - Prof. Dr. Norbert ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

108 7. CIX module performance under X-ray irradiation<br />

7.3 Average photon energy<br />

The third key feature of CIX 0.2 is its ability to measure the average energy of the<br />

absorbed spectrum. In order to evaluate this characteristic, the average photon energy<br />

reconstruction was tested on a homogeneous wedge-shaped aluminum absorber. Like this<br />

it is possible to exactly simulate the transmission spectrum behind the absorber as well as<br />

the resulting absorption spectrum in the detector. The simulation used for this purpose<br />

is the same as in section 6.4.<br />

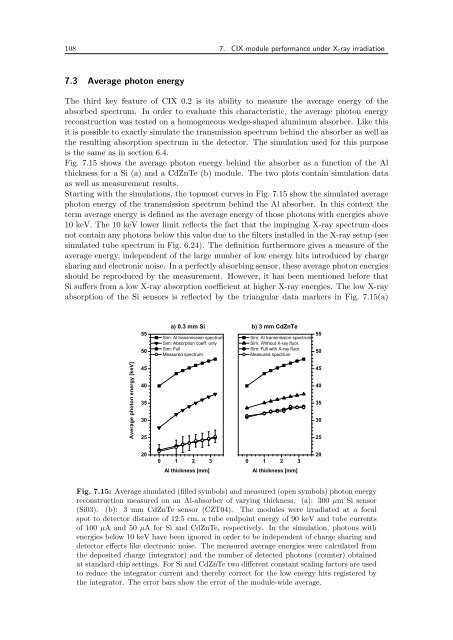

Fig. 7.15 shows the average photon energy behind the absorber as a function of the Al<br />

thickness for a Si (a) and a CdZnTe (b) module. The two plots contain simulation data<br />

as well as measurement results.<br />

Starting with the simulations, the topmost curves in Fig. 7.15 show the simulated average<br />

photon energy of the transmission spectrum behind the Al absorber. In this context the<br />

term average energy is defined as the average energy of those photons with energies above<br />

10 keV. The 10 keV lower limit reflects the fact that the impinging X-ray spectrum does<br />

not contain any photons below this value due to the filters installed in the X-ray setup (see<br />

simulated tube spectrum in Fig. 6.24). The definition furthermore gives a measure of the<br />

average energy, independent of the large number of low energy hits introduced by charge<br />

sharing and electronic noise. In a perfectly absorbing sensor, these average photon energies<br />

should be reproduced by the measurement. However, it has been mentioned before that<br />

Si suffers from a low X-ray absorption coefficient at higher X-ray energies. The low X-ray<br />

absorption of the Si sensors is reflected by the triangular data markers in Fig. 7.15(a)<br />

A v e r a g e p h o to n e n e r g y [k e V ]<br />

5 5<br />

5 0<br />

4 5<br />

4 0<br />

3 5<br />

3 0<br />

2 5<br />

2 0<br />

a ) 0 .3 m m S i<br />

S im : A l tra n s m is s io n s p e c tru m<br />

S im : A b s o rp tio n c o e ff. o n ly<br />

S im : F u ll<br />

M e a s u re d s p e c tru m<br />

0 1 2 3<br />

A l th ic k n e s s [m m ]<br />

b ) 3 m m C d Z n T e<br />

S im : A l tra n s m is s io n s p e c tru m<br />

S im : W ith o u t X -ra y flu o r.<br />

S im : F u ll w ith X -ra y flu o r.<br />

M e a s u re d s p e c tru m<br />

0 1 2 3<br />

A l th ic k n e s s [m m ]<br />

Fig. 7.15: Average simulated (filled symbols) and measured (open symbols) photon energy<br />

reconstruction measured on an Al-absorber of varying thickness. (a): 300 µm Si sensor<br />

(Si03). (b): 3 mm CdZnTe sensor (CZT04). The modules were irradiated at a focal<br />

spot to detector distance of 12.5 cm, a tube endpoint energy of 90 keV and tube currents<br />

of 100 µA and 50 µA for Si and CdZnTe, respectively. In the simulation, photons with<br />

energies below 10 keV have been ignored in order to be independent of charge sharing and<br />

detector effects like electronic noise. The measured average energies were calculated from<br />

the deposited charge (integrator) and the number of detected photons (counter) obtained<br />

at standard chip settings. For Si and CdZnTe two different constant scaling factors are used<br />

to reduce the integrator current and thereby correct for the low energy hits registered by<br />

the integrator. The error bars show the error of the module-wide average.<br />

5 5<br />

5 0<br />

4 5<br />

4 0<br />

3 5<br />

3 0<br />

2 5<br />

2 0