- Page 2 and 3:

Mechanics of Fluids

- Page 4 and 5:

Mechanics of Fluids Eighth edition

- Page 6 and 7:

Contents Preface to the eighth edit

- Page 8 and 9:

8 Boundary Layers, Wakes and Other

- Page 10 and 11:

Preface to the eighth edition In th

- Page 12 and 13:

Fundamental concepts 1 The aim of C

- Page 14 and 15:

1.1.1 Molecular structure The diffe

- Page 16 and 17:

therefore, to have in place systems

- Page 18 and 19:

has been a strong movement in favou

- Page 20 and 21:

Notation, dimensions, units and rel

- Page 22 and 23:

is nearer 2 m, rather than 1 m. Her

- Page 24 and 25:

Properties of fluids 13 The relativ

- Page 26 and 27:

that is, p1 − p3 = 1 2BC ϱax (1.

- Page 28 and 29:

that there is an almost perfect vac

- Page 30 and 31:

calorically perfect. (Some writers

- Page 32 and 33:

As a liquid is compressed its molec

- Page 34 and 35:

or τ = µ ∂u ∂y (1.9) where µ

- Page 36 and 37:

shared among the occupants of bb, a

- Page 38 and 39:

the origin with slope equal to µ (

- Page 40 and 41:

The interplay of these various forc

- Page 42 and 43:

non-uniformity is always encountere

- Page 44 and 45:

z direction and therefore the same

- Page 46 and 47:

Although Reynolds used water in his

- Page 48 and 49:

cylinder. For a certain range of Re

- Page 50 and 51:

The roles of experimentation and th

- Page 52 and 53:

A flow model which assumes steady,

- Page 54 and 55:

2.1 INTRODUCTION Fluid statics 2 Fl

- Page 56 and 57:

3. dp/dz =−ϱg. (Since the pressu

- Page 58 and 59:

that is, dp p =−g dz R T Variatio

- Page 60 and 61:

atmosphere it is termed vacuum or s

- Page 62 and 63:

at its centreline be p. Then, provi

- Page 64 and 65:

possible, and a sloping manometer m

- Page 66 and 67:

The amount of liquid B on each side

- Page 68 and 69:

In a pressure transducer the pressu

- Page 70 and 71:

where the suffixes C and Oy indicat

- Page 72 and 73:

surface (where the pressure is atmo

- Page 74 and 75:

which has different depths of water

- Page 76 and 77:

Hydrostatic thrusts on submerged su

- Page 78 and 79:

plane and may then be combined into

- Page 80 and 81:

Since all the elemental thrusts are

- Page 82 and 83:

neglected when a body is weighed on

- Page 84 and 85:

couple acting on the body in its di

- Page 86 and 87:

centre of buoyancy on to the transv

- Page 88 and 89:

move, but also the centre of gravit

- Page 90 and 91:

that is, W(OG) = (W + F)(OB + BM) =

- Page 92 and 93:

is given by ∂p ∂x =−ϱax Equi

- Page 94 and 95:

Then ∂p/∂ξ = 0 by definition o

- Page 96 and 97:

2.5 Two small vessels are connected

- Page 98 and 99:

2.18 In the vertical end of an oil

- Page 100 and 101:

The principles governing fluids in

- Page 102 and 103:

planes B and C (Fig. 3.2), δs bein

- Page 104 and 105:

an actual fluid is thus often remar

- Page 106 and 107:

density are small. Then eqn 3.9 has

- Page 108 and 109:

General energy equation for steady

- Page 110 and 111:

General energy equation for steady

- Page 112 and 113:

General energy equation for steady

- Page 114 and 115:

General energy equation for steady

- Page 116 and 117:

− Energy loss to friction/time Ma

- Page 118 and 119:

a decrease of pressure (provided th

- Page 120 and 121:

in the neighbourhood of B results i

- Page 122 and 123:

it is difficult to measure the heig

- Page 124 and 125:

The diagram illustrates an orifice

- Page 126 and 127:

� depth h below the free surface

- Page 128 and 129:

Solution (a) We consider first the

- Page 130 and 131:

of the same liquid. A vena contract

- Page 132 and 133:

To ensure that the pressure measure

- Page 134 and 135:

Since �h = p1 − p2 ϱwg the flo

- Page 136 and 137:

For consistency with the mathematic

- Page 138 and 139:

showing the essential form of the r

- Page 140 and 141:

With the same assumptions used in d

- Page 142 and 143:

∴ Velocity of approach = 0.0660 m

- Page 144 and 145:

of the base of the notch. Assume th

- Page 146 and 147:

Our aim now is to derive a relation

- Page 148 and 149:

The velocity, in general, varies fr

- Page 150 and 151:

the control volume is � ϱ1u1ux1

- Page 152 and 153:

Applications of the momentum equati

- Page 154 and 155:

that the resultant force on the flu

- Page 156 and 157:

The existence of the reaction may b

- Page 158 and 159:

our reference axes attached to the

- Page 160 and 161:

of increase of x-momentum is � D

- Page 162 and 163:

This is a simplified picture of wha

- Page 164 and 165:

since u4 −u1 is the velocity of t

- Page 166 and 167:

(1) u 1 (2) (3) (4) Assume a sea le

- Page 168 and 169:

and frictional effects to be neglig

- Page 170 and 171:

Physical similarity and dimensional

- Page 172 and 173:

A well-known example of kinematic s

- Page 174 and 175:

polygon. Now a polygon can be compl

- Page 176 and 177:

The condition for dynamic similarit

- Page 178 and 179:

equality of the Mach numbers is not

- Page 180 and 181:

Consider the incompressible flow al

- Page 182 and 183:

moving in a straight line with cons

- Page 184 and 185:

of the analysis, and its correct im

- Page 186 and 187:

Note: a suffix has been attached to

- Page 188 and 189:

For example, the parameter Fϱ/µ 2

- Page 190 and 191:

The application of dynamic similari

- Page 192 and 193:

atmospheric air, the dynamic viscos

- Page 194 and 195:

gives rise to waves on the surface.

- Page 196 and 197:

To be tested, the model must theref

- Page 198 and 199:

it follows that Hence V2 V1 = P2 P1

- Page 200 and 201:

5.5 A torpedo-shaped object 900 mm

- Page 202 and 203:

Laminar flow between solid boundari

- Page 204 and 205:

the place of y: τ = µ ∂u ∂r A

- Page 206 and 207:

compensate for the reduction in vel

- Page 208 and 209:

The expression for the total discha

- Page 210 and 211:

etween the resisting viscous forces

- Page 212 and 213:

must be zero so as to meet the requ

- Page 214 and 215:

Example 6.2 Two stationary, paralle

- Page 216 and 217:

Thus for any value of y the velocit

- Page 218 and 219:

Steady laminar flow between moving

- Page 220 and 221:

in eqn 6.24 we obtain � D Vp 2

- Page 222 and 223:

and the passage of the liquid level

- Page 224 and 225:

this book, it is important to give

- Page 226 and 227:

6.6.4 Rotary viscometers A simple m

- Page 228 and 229:

The torque T on the cylinder of rad

- Page 230 and 231:

stationary when the outer cylinder

- Page 232 and 233:

Fundamentals of the theory of hydro

- Page 234 and 235:

Fundamentals of the theory of hydro

- Page 236 and 237:

Fundamentals of the theory of hydro

- Page 238 and 239:

Fundamentals of the theory of hydro

- Page 240 and 241:

part of the bearing then gives when

- Page 242 and 243:

e determined by our analysis.) From

- Page 244 and 245:

Fundamentals of the theory of hydro

- Page 246 and 247:

Fundamentals of the theory of hydro

- Page 248 and 249:

where a = 6µ�R h3 dh pc dx Funda

- Page 250 and 251:

Integrating this between θ = 0 and

- Page 252 and 253:

Rearrangement of eqn 6.71 and subst

- Page 254 and 255:

6.4 A cylindrical drum of length l

- Page 256 and 257:

7.1 INTRODUCTION Flow and losses in

- Page 258 and 259:

a maximum value of 2.0. The line CD

- Page 260 and 261:

America the friction factor commonl

- Page 262 and 263:

course, quite different from the ro

- Page 264 and 265:

Variation of friction factor 253 Fi

- Page 266 and 267:

straightforward manner without iter

- Page 268 and 269:

Distribution of shear stress in a c

- Page 270 and 271:

7.5 FRICTION IN NON-CIRCULAR CONDUI

- Page 272 and 273:

estimated by simple theory. The pip

- Page 274 and 275:

the junction, the curvature of the

- Page 276 and 277:

particular, the performance of a di

- Page 278 and 279:

A pipe bend thus causes a loss of h

- Page 280 and 281:

cross-sectional area available in t

- Page 282 and 283:

correlating experimental data on th

- Page 284 and 285:

to do this. But sub-atmospheric pre

- Page 286 and 287:

For systems comprising only short r

- Page 288 and 289:

7.8 PIPES IN COMBINATION 7.8.1 Pipe

- Page 290 and 291:

2. There can be only one value of h

- Page 292 and 293:

So For two pipes in parallel, and s

- Page 294 and 295:

7.9 CONDITIONS NEAR THE PIPE ENTRY

- Page 296 and 297:

where u denotes the mean velocity i

- Page 298 and 299:

Assuming that entry and exit losses

- Page 300 and 301:

of one-per-revolution electrical co

- Page 302 and 303:

of the piping system, this meter is

- Page 304 and 305:

losses, calculate (a) the total pow

- Page 306 and 307:

How are the running costs altered i

- Page 308 and 309:

main. The depth of water in the tan

- Page 310 and 311:

the features of boundary layer flow

- Page 312 and 313:

the surface other considerations ar

- Page 314 and 315:

and θ = = = � δ u 0 um � δ 0

- Page 316 and 317:

The momentum equation applied to th

- Page 318 and 319:

1 = y η δ The laminar boundary la

- Page 320 and 321:

Table 8.1 Comparison of results for

- Page 322 and 323:

and � � ∂f (η) B = ∂η A =

- Page 324 and 325:

From equation 8.17, the frictional

- Page 326 and 327:

The turbulent boundary layer on a s

- Page 328 and 329:

Hence F = 0.037ϱu 2 m l(Re l) −1

- Page 330 and 331:

From eqn 8.29 Hence and xt − x0 x

- Page 332 and 333:

from it. This breakaway before the

- Page 334 and 335:

this expression into eqn 8.31 we ge

- Page 336 and 337:

When, for example, a ship moves thr

- Page 338 and 339:

separate vortices in an inviscid fl

- Page 340 and 341:

8.8.4 Profile drag of two-dimension

- Page 342 and 343:

are negligible. With reduction in t

- Page 344 and 345:

Fig. 8.14 Drag coefficients of smoo

- Page 346 and 347:

sphere is falling through the atmos

- Page 348 and 349:

At high Reynolds numbers, the varia

- Page 350 and 351:

this does not prevent the continual

- Page 352 and 353:

Eddy viscosity and the mixing lengt

- Page 354 and 355:

Eddy viscosity and the mixing lengt

- Page 356 and 357:

Velocity distribution in turbulent

- Page 358 and 359:

then, although at very small values

- Page 360 and 361:

as η → 1 and (1 − η) is then

- Page 362 and 363:

When f −1/2 − 4 log 10 (d/k) is

- Page 364 and 365:

comparable with the velocity of sou

- Page 366 and 367:

The x, y and z components of the mo

- Page 368 and 369:

y y x i-1, j+1 i, j+1 i+1, j+1 i-1,

- Page 370 and 371:

e completely covered by a turbulent

- Page 372 and 373:

9.1 INTRODUCTION The flow of an inv

- Page 374 and 375:

Now consider another point P ′′

- Page 376 and 377:

number of smaller ones of which M a

- Page 378 and 379:

distortion, the element is thus not

- Page 380 and 381:

Any function φ that satisfies Lapl

- Page 382 and 383:

ecome perfect squares - except wher

- Page 384 and 385:

fluid, and the flow net indicates t

- Page 386 and 387:

9.6.2 Flow from a line source A sou

- Page 388 and 389:

higher orders of small magnitudes b

- Page 390 and 391:

Combining eqns 9.16 and 9.17 we obt

- Page 392 and 393:

9.6.5 Forced (rotational) vortex Th

- Page 394 and 395:

For a free vortex qR = constant = K

- Page 396 and 397:

source is unable to move to the lef

- Page 398 and 399:

Also we note that the source is pos

- Page 400 and 401:

as shown in Fig. 9.23, encloses all

- Page 402 and 403:

eqn 9.23 becomes ψ =−U � r −

- Page 404 and 405:

Thus the magnitude of the velocity

- Page 406 and 407:

At a stagnation point, qt = 0 and t

- Page 408 and 409:

function of the combined flow is gi

- Page 410 and 411:

or, more approximately, that betwee

- Page 412 and 413:

Then dw dz =−U =−u + iv Hence u

- Page 414 and 415:

An introduction to elementary aerof

- Page 416 and 417:

ound the aerofoil, its magnitude be

- Page 418 and 419:

and lower layers. Since the vortex

- Page 420 and 421:

where Ɣ0 represents the circulatio

- Page 422 and 423:

9.7 An open cylindrical vessel, hav

- Page 424 and 425:

steadily south-east at 6 m · s −

- Page 426 and 427:

10.2 TYPES OF FLOW IN OPEN CHANNELS

- Page 428 and 429:

The steady-flow energy equation for

- Page 430 and 431:

where the hs represent vertical dep

- Page 432 and 433:

to the turbulent rough flow regime

- Page 434 and 435:

selection of an appropriate value r

- Page 436 and 437:

10.6 OPTIMUM SHAPE OF CROSS-SECTION

- Page 438 and 439:

oughness coefficient n is independe

- Page 440 and 441:

thrust divided by width of the chan

- Page 442 and 443:

which the waves follow one another

- Page 444 and 445:

The conditions for the critical dep

- Page 446 and 447:

y downstream conditions. In these c

- Page 448 and 449:

may be obtained by reducing eqn 10.

- Page 450 and 451:

this depth is greater than the crit

- Page 452 and 453:

The dissipation of energy is by no

- Page 454 and 455:

friction, the steady-flow momentum

- Page 456 and 457:

Fig. 10.28 Notice that, for a chann

- Page 458 and 459:

calculated, and then H + u2 1 /2g m

- Page 460 and 461:

Fig. 10.32 If the depth of flow ove

- Page 462 and 463:

(Section 10.11.1). Rapid flow can n

- Page 464 and 465:

where 0 ≤ θ ≤ 90 ◦ and sin

- Page 466 and 467:

(a) The continuity equation is The

- Page 468 and 469:

oundaries. It can occur when the fl

- Page 470 and 471:

into eqn 10.39 we obtain whence dh

- Page 472 and 473:

Table 10.2 Gradually varied flow 46

- Page 474 and 475:

The slope of a given channel may, o

- Page 476 and 477:

direction. The effect of any bounda

- Page 478 and 479:

This momentum term, however, is pro

- Page 480 and 481:

With surface tension effects ignore

- Page 482 and 483:

are for waves of small amplitude) w

- Page 484 and 485:

when the wave was formed. The lengt

- Page 486 and 487:

At a particular instant the crests

- Page 488 and 489:

Hence h = 2.65λ 2π = 2.65 × 225

- Page 490 and 491:

As the ratio of these velocity comp

- Page 492 and 493:

water is impulsively displaced and

- Page 494 and 495:

is relative movement of one layer o

- Page 496 and 497:

the channel bed a drop of 150 mm in

- Page 498 and 499:

11.1 INTRODUCTION Compressible flow

- Page 500 and 501:

energy ÷ mass, so that the dimensi

- Page 502 and 503:

Energy equation with variable densi

- Page 504 and 505:

Solution (a) From the equation of s

- Page 506 and 507:

whence (c − u)δρ = (ρ + δρ)

- Page 508 and 509:

the sonic velocity as supersonic (M

- Page 510 and 511:

velocity into the undisturbed fluid

- Page 512 and 513:

whence p2 p1 = 1 + γ M2 1 1 + γ M

- Page 514 and 515:

of eqns 11.2 and 11.20 T0 T u2 = 1

- Page 516 and 517:

the temperature rises greatly (say

- Page 518 and 519:

Fig. 11.10 Oblique shock relations

- Page 520 and 521:

however, that for a given upstream

- Page 522 and 523:

The deflection through the first wa

- Page 524 and 525:

As δθ is very small, cos δθ →

- Page 526 and 527:

eqn 11.41. Substituting M 2 − 1 =

- Page 528 and 529:

oundaries, both of which are curved

- Page 530 and 531:

For supersonic flow eqn 11.45 is no

- Page 532 and 533:

Some general relations for one-dime

- Page 534 and 535:

of minimum cross-section the veloci

- Page 536 and 537:

downstream of the minimum cross-sec

- Page 538 and 539:

‘telegraphed’ upstream and a pr

- Page 540 and 541:

the external pressure. This compres

- Page 542 and 543:

Compressible flow in pipes of const

- Page 544 and 545:

Table 11.2 Changes with distance al

- Page 546 and 547:

Compressible flow in pipes of const

- Page 548 and 549:

Compressible flow in pipes of const

- Page 550 and 551:

From the Fanno Tables at pc/pB = 0.

- Page 552 and 553:

Compressible flow in pipes of const

- Page 554 and 555:

Therefore and M1 = u1 a 24.5 m · s

- Page 556 and 557:

drag. The abrupt pressure rise thro

- Page 558 and 559:

Analogy between compressible flow a

- Page 560 and 561:

is, on ∂2n ∂y2 + ∂2 � n ∂

- Page 562 and 563:

and the mass flow rate in the duct.

- Page 564 and 565:

11.18 Air flows isothermally at 15

- Page 566 and 567:

12.2 INERTIA PRESSURE Any volume of

- Page 568 and 569:

Equation 12.3 indicates that u beco

- Page 570 and 571:

would come to rest later. Although

- Page 572 and 573:

a pressure wave in a gas; here we r

- Page 574 and 575:

value in eqn 12.7 gives that is, wh

- Page 576 and 577:

the moment disregarded. An increase

- Page 578 and 579:

at this point remains constant for

- Page 580 and 581:

In addition to the reflection of wa

- Page 582 and 583:

is closed so that the area coeffici

- Page 584 and 585:

The pressure diagrams show that for

- Page 586 and 587:

12.3.4 The method of characteristic

- Page 588 and 589:

Pressure transients 577 Multiplying

- Page 590 and 591:

and velocities are known, then for

- Page 592 and 593:

For pipe 2, and hence K ′ = c2 =

- Page 594 and 595: (instantaneously, we will assume) a

- Page 596 and 597: The one-dimensional continuity rela

- Page 598 and 599: to accommodate instantaneous comple

- Page 600 and 601: 12.2 A turbine which normally opera

- Page 602 and 603: 13.1 INTRODUCTION Fluid machines13

- Page 604 and 605: flow. By way of illustration we sha

- Page 606 and 607: would obviate the changes of pressu

- Page 608 and 609: demand for electric power - for exa

- Page 610 and 611: Turbines 599 Fig. 13.7 Runner of Pe

- Page 612 and 613: determined, multiplication by the r

- Page 614 and 615: Substituting for �vw from eqn 13.

- Page 616 and 617: ut the larger its value the more bu

- Page 618 and 619: ate of flow possible is achieved wh

- Page 620 and 621: the turbine. For the high heads nor

- Page 622 and 623: The integrals in eqns 13.4 and 13.5

- Page 624 and 625: diagram of Fig. 13.16 we have Simil

- Page 626 and 627: would be sufficient to describe the

- Page 628 and 629: Table 13.1 Type of turbine Approxim

- Page 630 and 631: ∴ Hydraulic efficiency = Overall

- Page 632 and 633: If either z (the height of the turb

- Page 634 and 635: ∴ Hydraulic efficiency = u1vw1/gH

- Page 636 and 637: shows the general effect of change

- Page 638 and 639: an unmixed blessing and, except for

- Page 640 and 641: orbiting space-craft, for example,

- Page 642 and 643: Losses are also possible at the inl

- Page 646 and 647: It should be noted that the values

- Page 648 and 649: ∴ (β1)A = arctan(va/u) = arctan(

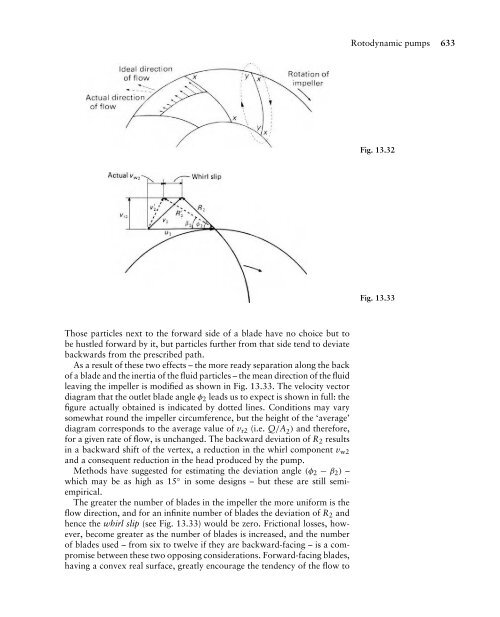

- Page 650 and 651: so much that the aerofoil stalls (a

- Page 652 and 653: Use these data to deduce the pump c

- Page 654 and 655: Manometric efficiency = 0.75 = gH/u

- Page 656 and 657: and CP = P/ϱω 3 D 5 in place of Q

- Page 658 and 659: yields h 1 = h f = 4fl d ≈ (100Q)

- Page 660 and 661: (iii) the power dissipated by pipe

- Page 662 and 663: Large numbers of test data for pump

- Page 664 and 665: educed by rounding the inlet edges

- Page 666 and 667: further: the turbine part then remo

- Page 668 and 669: for reaction turbines: 1 − η = 1

- Page 670 and 671: 75 mm wide at outlet. The blades oc

- Page 672 and 673: Losses at valves, etc. are estimate

- Page 674 and 675: APPENDIX Units and conversion 1 fac

- Page 676 and 677: Table A1.4 (contd.) Force 32.17 pdl

- Page 678 and 679: APPENDIX Physical constants and 2 p

- Page 680 and 681: Kinematic viscosity mm 2 ·s -1 App

- Page 682 and 683: Range II: 11 000 m ≤ z ≤ 20 000

- Page 684 and 685: Table A3.1 (contd.) M 1 M 2 p 2/p 1

- Page 686 and 687: Table A3.2 Isentropic flow M p/po

- Page 688 and 689: Table A3.3 Adiabatic flow with fric

- Page 690 and 691: APPENDIX 4 Algebraic symbols Table

- Page 692 and 693: Table A4.1 (contd.) Symbol Definiti

- Page 694 and 695:

Table A4.1 (contd.) Symbol Definiti

- Page 696 and 697:

Answers to problems 1.1 56.2 m 3 1.

- Page 698 and 699:

8.14 0.002955, 2.866 m · s −1 ,

- Page 700 and 701:

Absolute pressure 46 Absolute visco

- Page 702 and 703:

Eccentricity 230 Eccentricity ratio

- Page 704 and 705:

Mach angle 498 intersection 510-1 r

- Page 706 and 707:

Slip in fluid couplings 652 in reci

- Page 708:

eBooks - at www.eBookstore.tandf.co