Independent Review of MSHA's Actions at Crandall Canyon Mine

Independent Review of MSHA's Actions at Crandall Canyon Mine

Independent Review of MSHA's Actions at Crandall Canyon Mine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Rocprops were chosen by the oper<strong>at</strong>or due to their capability to be pressurized between the<br />

ro<strong>of</strong> and floor, thus making them an active support. Rocprops had been used by the<br />

company <strong>at</strong> its Aberdeen <strong>Mine</strong> for rib protection in bounce-prone, longwall headg<strong>at</strong>e entries.<br />

Chain link fence and one wire rope were used in conjunction with the Rocprops <strong>at</strong> the<br />

Aberdeen <strong>Mine</strong>. The wire rope was either wrapped around the coal pillar or anchored in some<br />

manner in the crosscuts to prevent the Rocprops from being dislodged in the event <strong>of</strong> a<br />

bounce. However, <strong>at</strong> the <strong>Crandall</strong> <strong>Canyon</strong> <strong>Mine</strong> the wire ropes could not be wrapped around<br />

the coal pillars and were anchored only on one end in the outby crosscuts due to the blockage<br />

from the coal rubble. Three wire ropes were used to secure each Rocprop to the adjoining<br />

Rocprops, which essentially tied them together.<br />

Timbers with “Jackpots” were installed in the No. 1 entry in appropri<strong>at</strong>e areas where<br />

additional supports were needed in areas outby crosscut 120. Jackpots are supplemental<br />

devices placed between a timber and the ro<strong>of</strong> and expand as fluid is pumped into them<br />

through a pressure relief valve to provide some measure <strong>of</strong> positive support. Rocprops<br />

were used exclusively beyond crosscut 120 to provide l<strong>at</strong>eral support as rescue efforts<br />

advanced up the No. 1 entry.<br />

As work progressed in the No. 1 entry, the method <strong>of</strong> pressurizing the Rocprops was<br />

changed. Initially, a scoop’s power take <strong>of</strong>f (PTO) was used to drive a booster pump to<br />

increase the w<strong>at</strong>er pressure to 1100 psi. L<strong>at</strong>er, booster pumps were mounted on the<br />

continuous mining machine and ro<strong>of</strong> bolting machine so they could be used when in the face<br />

area. This acceler<strong>at</strong>ed the install<strong>at</strong>ion process by elimin<strong>at</strong>ing the need for another piece <strong>of</strong><br />

59<br />

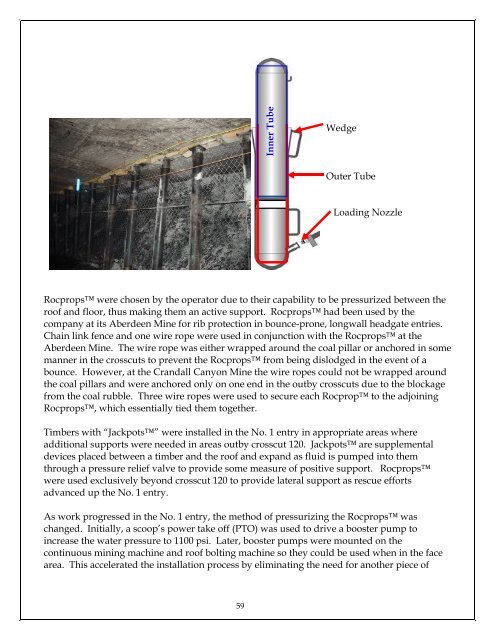

Inner Tube<br />

Wedge<br />

Outer Tube<br />

Loading Nozzle