Independent Review of MSHA's Actions at Crandall Canyon Mine

Independent Review of MSHA's Actions at Crandall Canyon Mine

Independent Review of MSHA's Actions at Crandall Canyon Mine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Research Engineer <strong>of</strong> the NIOSH Pittsburgh Research Labor<strong>at</strong>ory, and an intern<strong>at</strong>ionally<br />

recognized expert on standing ro<strong>of</strong> supports, for his recommend<strong>at</strong>ion for a support system.<br />

Barczak recommended the use <strong>of</strong> Rocprops for the conditions encountered.<br />

Billy Owens, District 9 Ro<strong>of</strong> Control Branch Supervisor, had extensive experience in the use <strong>of</strong><br />

Rocprops. However, he st<strong>at</strong>ed th<strong>at</strong> he was not consulted or involved in any way with the<br />

support selection used during the rescue effort <strong>at</strong> the <strong>Crandall</strong> <strong>Canyon</strong> <strong>Mine</strong>. He further<br />

st<strong>at</strong>ed th<strong>at</strong> he had seen individual Rocprops dislodged as the result <strong>of</strong> a bounce <strong>at</strong> the<br />

Aberdeen <strong>Mine</strong>. From this experience, he knew the importance <strong>of</strong> the wire ropes being<br />

wrapped around the pillars or securely anchored by bolting to the ro<strong>of</strong>. At Aberdeen, even<br />

though individual Rocprops were dislodged, they were restrained from further movement<br />

because both ends <strong>of</strong> the wire rope were secured. At <strong>Crandall</strong> <strong>Canyon</strong>, the wire ropes were<br />

not anchored as they were <strong>at</strong> the Aberdeen <strong>Mine</strong>. Owens st<strong>at</strong>ed th<strong>at</strong> the inby end <strong>of</strong> the wire<br />

ropes could have been “bolted to the ro<strong>of</strong>”.<br />

During interviews, several <strong>of</strong> the MSHA inspectors who were monitoring the underground<br />

work st<strong>at</strong>ed th<strong>at</strong> they had concerns over the adequacy <strong>of</strong> the Rocprops providing protection<br />

from a future bounce. They were confident in the Rocprop as vertical ro<strong>of</strong> support, but<br />

questioned its ability to withstand l<strong>at</strong>eral forces resulting from a bounce. Inspectors st<strong>at</strong>ed<br />

th<strong>at</strong> they had seen Rocprops dislodged <strong>at</strong> the Aberdeen <strong>Mine</strong>. Allyn Davis, District 9<br />

Manager, st<strong>at</strong>ed th<strong>at</strong> he had heard th<strong>at</strong> Rocprops had failed <strong>at</strong> Aberdeen <strong>Mine</strong> and th<strong>at</strong> was<br />

one <strong>of</strong> the reasons for requiring three wire ropes instead <strong>of</strong> one.<br />

Several Rocprops were dislodged during the rescue effort by a shuttle car negoti<strong>at</strong>ing the<br />

turn from the No. 1 entry into the belt entry. One inspector documented in his notes,<br />

following a bounce th<strong>at</strong> occurred on August 15 th , th<strong>at</strong> it appeared the tops and bottoms <strong>of</strong> the<br />

Rocprops had moved, and he questioned their ability to provide support. Another inspector<br />

st<strong>at</strong>ed th<strong>at</strong> he thought th<strong>at</strong> the bottoms <strong>of</strong> some <strong>of</strong> the Rocprops in the No. 1 entry had been<br />

pushed toward the center <strong>of</strong> the entry after m<strong>at</strong>erial had accumul<strong>at</strong>ed behind the chain link<br />

fencing th<strong>at</strong> was <strong>at</strong>tached behind the props. These inspectors also st<strong>at</strong>ed th<strong>at</strong> their input was<br />

never solicited in the decision to use or evalu<strong>at</strong>ion <strong>of</strong> Rocprops during the rescue effort.<br />

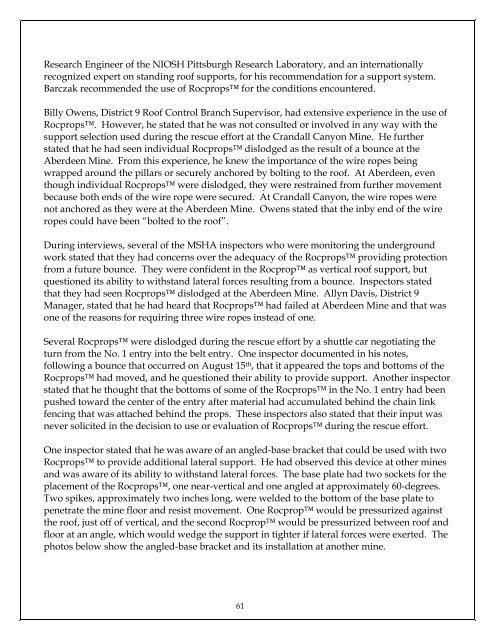

One inspector st<strong>at</strong>ed th<strong>at</strong> he was aware <strong>of</strong> an angled-base bracket th<strong>at</strong> could be used with two<br />

Rocprops to provide additional l<strong>at</strong>eral support. He had observed this device <strong>at</strong> other mines<br />

and was aware <strong>of</strong> its ability to withstand l<strong>at</strong>eral forces. The base pl<strong>at</strong>e had two sockets for the<br />

placement <strong>of</strong> the Rocprops, one near-vertical and one angled <strong>at</strong> approxim<strong>at</strong>ely 60-degrees.<br />

Two spikes, approxim<strong>at</strong>ely two inches long, were welded to the bottom <strong>of</strong> the base pl<strong>at</strong>e to<br />

penetr<strong>at</strong>e the mine floor and resist movement. One Rocprop would be pressurized against<br />

the ro<strong>of</strong>, just <strong>of</strong>f <strong>of</strong> vertical, and the second Rocprop would be pressurized between ro<strong>of</strong> and<br />

floor <strong>at</strong> an angle, which would wedge the support in tighter if l<strong>at</strong>eral forces were exerted. The<br />

photos below show the angled-base bracket and its install<strong>at</strong>ion <strong>at</strong> another mine.<br />

61