Enamels and enamelling; an introduction to the preparation and ...

Enamels and enamelling; an introduction to the preparation and ...

Enamels and enamelling; an introduction to the preparation and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

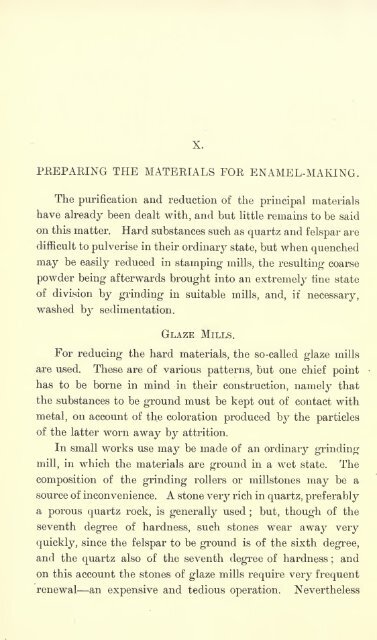

X.<br />

PEEPARING THE MATERIALS FOR ENAMEL-MAKING.<br />

The purification <strong><strong>an</strong>d</strong> reduction of <strong>the</strong> principal materials<br />

have already been dealt with, <strong><strong>an</strong>d</strong> but little remains <strong>to</strong> be said<br />

on this matter. Hard subst<strong>an</strong>ces such as quartz <strong><strong>an</strong>d</strong> felspar are<br />

difficult <strong>to</strong> pulverise in <strong>the</strong>ir ordinary state, but when quenched<br />

may be easily reduced in stamping mills, <strong>the</strong> resulting coarse<br />

powder being afterwards brought in<strong>to</strong> <strong>an</strong> extremely tine state<br />

of division by grinding in suitable mills, <strong><strong>an</strong>d</strong>, if necessary,<br />

washed by sedimentation.<br />

GLAZE MILLS.<br />

For reducing <strong>the</strong> hard materials, <strong>the</strong> so-called glaze mills<br />

are used. These are of various patterns, but one chief point<br />

has <strong>to</strong> be borne in mind in <strong>the</strong>ir construction, namely that<br />

<strong>the</strong> subst<strong>an</strong>ces <strong>to</strong> be ground must be kept out of contact with<br />

metal, on account of <strong>the</strong> coloration produced by <strong>the</strong> particles<br />

of <strong>the</strong> latter worn away by attrition.<br />

In small works use may be made of <strong>an</strong> ordinary grinding<br />

mill, in which <strong>the</strong> materials are ground in a wet state. The<br />

composition of <strong>the</strong> grinding rollers or mills<strong>to</strong>nes may be a<br />

source of inconvenience. A s<strong>to</strong>ne very rich in quartz, preferably<br />

of <strong>the</strong><br />

a porous quartz rock, is generally used ; but, though<br />

seventh degree of hardness, such s<strong>to</strong>nes wear away very<br />

quickly, since <strong>the</strong> felspar <strong>to</strong> be ground is of <strong>the</strong> sixth degree,<br />

<strong><strong>an</strong>d</strong> <strong>the</strong> quartz also of <strong>the</strong> seventh degree of hardness ; <strong><strong>an</strong>d</strong><br />

on this account <strong>the</strong> s<strong>to</strong>nes of glaze mills require very frequent<br />

renewal <strong>an</strong> expensive <strong><strong>an</strong>d</strong> tedious operation. Never<strong>the</strong>less