Enamels and enamelling; an introduction to the preparation and ...

Enamels and enamelling; an introduction to the preparation and ...

Enamels and enamelling; an introduction to the preparation and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

XXVI.<br />

DIAL-PLATE ENAMELLING.<br />

The m<strong>an</strong>ufacture of dial-plates for clocks is a special<br />

business, <strong><strong>an</strong>d</strong> generally consists in covering sheet copper with<br />

white enamel. The thin sheet copper, cut <strong>to</strong> <strong>the</strong> desired size,<br />

is made bright <strong><strong>an</strong>d</strong> coated on both sides with perfectly white<br />

enamel, in fine powder mixed with water <strong><strong>an</strong>d</strong> laid on with a<br />

brush. As <strong>the</strong> enamel used is always very rich in tin oxide<br />

it covers well enough <strong>to</strong> be used in exceedingly thin layers.<br />

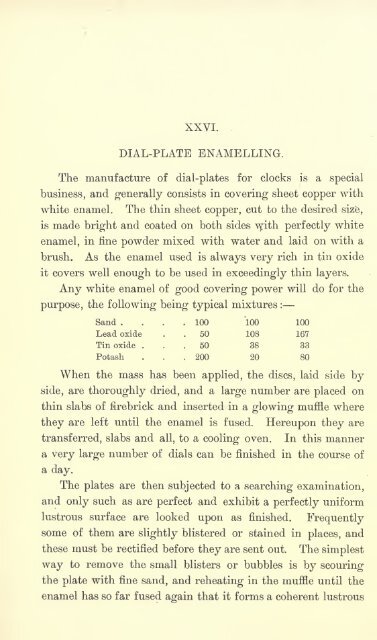

Any white enamel of good covering power will do for <strong>the</strong><br />

purpose, <strong>the</strong> following being typical mixtures :<br />

S<strong><strong>an</strong>d</strong> .... 100 100 100<br />

Lead oxide . . 50 108 167<br />

Tin oxide ... 50 38 33<br />

Potash ... 200 20 80<br />

When <strong>the</strong> mass has been applied, <strong>the</strong> discs, laid side by<br />

side, are thoroughly dried, <strong><strong>an</strong>d</strong> a large number are placed on<br />

thin slabs of firebrick <strong><strong>an</strong>d</strong> inserted in a glowing muffle where<br />

<strong>the</strong>y are left until <strong>the</strong> enamel is fused. Hereupon <strong>the</strong>y are<br />

tr<strong>an</strong>sferred, slabs <strong><strong>an</strong>d</strong> all, <strong>to</strong> a cooling oven. In this m<strong>an</strong>ner<br />

a very large number of dials c<strong>an</strong> be finished in <strong>the</strong> course of<br />

a day.<br />

The plates are <strong>the</strong>n subjected <strong>to</strong> a searching examination,<br />

<strong><strong>an</strong>d</strong> only such as are perfect <strong><strong>an</strong>d</strong> exhibit a perfectly uniform<br />

lustrous surface are looked upon as finished. Frequently<br />

some of <strong>the</strong>m are slightly blistered or stained in places, <strong><strong>an</strong>d</strong><br />

<strong>the</strong>se must be rectified before <strong>the</strong>y are sent out. The simplest<br />

way <strong>to</strong> remove <strong>the</strong> small blisters or bubbles is by scouring<br />

<strong>the</strong> plate with fine s<strong><strong>an</strong>d</strong>, <strong><strong>an</strong>d</strong> reheating in <strong>the</strong> muffle until <strong>the</strong><br />

enamel has so far fused again that it forms a coherent lustrous