Enamels and enamelling; an introduction to the preparation and ...

Enamels and enamelling; an introduction to the preparation and ...

Enamels and enamelling; an introduction to the preparation and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

APPLIANCES FOB SMELTING THE ENAMEL MASS. 109<br />

tents of <strong>the</strong> latter c<strong>an</strong> be examined, <strong>the</strong> plug at <strong>the</strong> bot<strong>to</strong>m<br />

knocked out, <strong><strong>an</strong>d</strong> a fresh charge inserted.<br />

The arr<strong>an</strong>gement of this class of furnace exhibits great<br />

similarity with that of <strong>an</strong> ordinary glass furnace, <strong><strong>an</strong>d</strong> is more<br />

economical in consumption of fuel th<strong>an</strong> when each crucible<br />

has <strong>to</strong> be heated separately.<br />

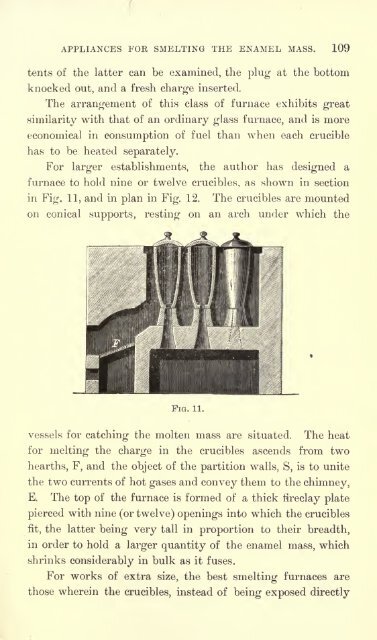

For larger establishments, <strong>the</strong> author has designed a<br />

furnace <strong>to</strong> hold nine or twelve crucibles, as shown in section<br />

in Fig. 11, <strong><strong>an</strong>d</strong> in pl<strong>an</strong> in Fig. 12. The crucibles are mounted<br />

on conical supports, resting on <strong>an</strong> arch under which <strong>the</strong><br />

FIG. 11.<br />

vessels for catching <strong>the</strong> molten mass are situated. The heat<br />

for melting <strong>the</strong> charge in <strong>the</strong> crucibles ascends from two<br />

hearths, F, <strong><strong>an</strong>d</strong> <strong>the</strong> object of <strong>the</strong> partition walls, S, is <strong>to</strong> unite<br />

<strong>the</strong> two currents of hot gases <strong><strong>an</strong>d</strong> convey <strong>the</strong>m <strong>to</strong> <strong>the</strong> chimney,<br />

E. The <strong>to</strong>p of <strong>the</strong> furnace is formed of a thick fireclay plate<br />

pierced with nine (or twelve) openings in<strong>to</strong> which <strong>the</strong> crucibles<br />

fit, <strong>the</strong> latter being very tall in proportion <strong>to</strong> <strong>the</strong>ir breadth,<br />

in order <strong>to</strong> hold a larger qu<strong>an</strong>tity of <strong>the</strong> enamel mass, which<br />

shrinks considerably in bulk as it fuses.<br />

For works of extra size, <strong>the</strong> best smelting furnaces are<br />

those wherein <strong>the</strong> crucibles, instead of being exposed directly