- Page 1 and 2: 3-1 [S100] SPECIFICATIONS AND SERVI

- Page 3 and 4: 3-1 [S600] SPECIFICATIONS AND SERVI

- Page 5 and 6: 3-1 [C100] COMPONENT PARTS 1. Trans

- Page 7 and 8: 3-1 [C2B0] COMPONENT PARTS 2. Drive

- Page 9 and 10: 3-1 [C3B0] COMPONENT PARTS 3. Main

- Page 11 and 12: 3-1 [C500] COMPONENT PARTS 5. Trans

- Page 13 and 14: 3-1 [W1A0] SERVICE PROCEDURE 1. Gen

- Page 15 and 16: 3-1 [W2A1] SERVICE PROCEDURE 2. Tra

- Page 17 and 18: 3-1 [W2A2] SERVICE PROCEDURE 2. Tra

- Page 19 and 20: 3-1 [W2B1] SERVICE PROCEDURE 2. Tra

- Page 21 and 22: 3-1 [W2B1] SERVICE PROCEDURE 2. Tra

- Page 23 and 24: 3-1 [W2B2] SERVICE PROCEDURE 2. Tra

- Page 25 and 26: 3-1 [W2B2] SERVICE PROCEDURE 2. Tra

- Page 27 and 28: 3-1 [W2B2] SERVICE PROCEDURE 2. Tra

- Page 29 and 30: 3-1 [W3A1] SERVICE PROCEDURE 3. Dri

- Page 31 and 32: 3-1 [W3B0] SERVICE PROCEDURE 3. Dri

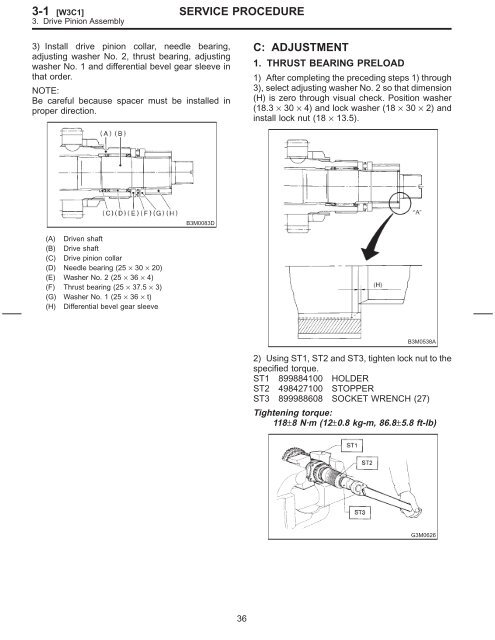

- Page 33: 3-1 [W3B3] SERVICE PROCEDURE 3. Dri

- Page 37 and 38: 3-1 [W4A1] SERVICE PROCEDURE 4. Mai

- Page 39 and 40: 3-1 [W4B0] SERVICE PROCEDURE 4. Mai

- Page 41 and 42: 3-1 [W4B2] SERVICE PROCEDURE 4. Mai

- Page 43 and 44: 3-1 [W5A0] SERVICE PROCEDURE 5. Tra

- Page 45 and 46: 3-1 [W5B5] SERVICE PROCEDURE 5. Tra

- Page 47 and 48: 3-1 [W5C3] SERVICE PROCEDURE 5. Tra

- Page 49 and 50: 3-1 [W5D0] SERVICE PROCEDURE 5. Tra

- Page 51 and 52: 3-1 [W6B0] SERVICE PROCEDURE 6. Fro

- Page 53 and 54: 3-1 [W7A0] SERVICE PROCEDURE 7. Cen

- Page 55 and 56: 3-1 [K200] DIAGNOSTICS 2. Different

- Page 57 and 58: 3. Transmission Control Element Typ

- Page 59 and 60: 7. Hydraulic Control and Lubricatio

- Page 61 and 62: 3-2 [S1100] SPECIFICATIONS AND SERV

- Page 63 and 64: 3-2 [S1100] SPECIFICATIONS AND SERV

- Page 65 and 66: No. Part Name Part Number (1) (2) (

- Page 67 and 68: C: TRANSMISSION CASE (REAR SIDE) (1

- Page 69 and 70: G: EXTENSION CASE SPECIFICATIONS AN

- Page 71 and 72: 2. Oil Pump (1) Oil pump rotor (2)

- Page 73 and 74: (1) Oil level gauge (2) Oil charger

- Page 75 and 76: 5. High Clutch and Reverse Clutch (

- Page 77 and 78: 7. Low Clutch and Low & Reverse Bra

- Page 79 and 80: 9. Differential Case (1) Crown gear

- Page 81 and 82: 1. General A: PRECAUTION When disas

- Page 83 and 84: 2) Torque converter clutch case En

- Page 85 and 86:

C: REMOVAL 1) Move select lever to

- Page 87 and 88:

3. Sensor (in transmission) A: INSP

- Page 89 and 90:

5) Remove control valve body. CAUTI

- Page 91 and 92:

5. Transfer Duty Solenoid and Trans

- Page 93 and 94:

2) Install extension case to transm

- Page 95 and 96:

CAUTION: Align ST with torque wrenc

- Page 97 and 98:

3. ENGINE BRAKE OPERATION Engine br

- Page 99 and 100:

3. EVALUATION Stall speed (at sea l

- Page 101 and 102:

2. TEST METHODS 1) Temporarily atta

- Page 103 and 104:

12. Overall Transmission A: SECTION

- Page 105 and 106:

10) Remove the oil cooler inlet and

- Page 107 and 108:

6) Remove the oil pan. NOTE: Use a

- Page 109 and 110:

19) Take out the thrust needle bear

- Page 111 and 112:

34) Remove parking support. B3M1088

- Page 113 and 114:

(2) Tighten four bolts to secure th

- Page 115 and 116:

Checking item Contact pattern Corre

- Page 117 and 118:

13) Apply vaseline to the groove on

- Page 119 and 120:

(1) Using a press and ST1, install

- Page 121 and 122:

19) Install planetary gear and low

- Page 123 and 124:

(2) Using ST, measure the distance

- Page 125 and 126:

4) Install the oil pan. (1) Attach

- Page 127 and 128:

(2) Measure the distance “ ” fr

- Page 129 and 130:

7) Install the oil charge pipe. CAU

- Page 131 and 132:

14. Reduction Driven Gear A: DISASS

- Page 133 and 134:

No. Part name SERVICE PROCEDURE Wir

- Page 135 and 136:

D: ASSEMBLY 1) Install accumulator

- Page 137 and 138:

5) Remove the inner and outer rotor

- Page 139 and 140:

C: ASSEMBLY 1) Measure dimension

- Page 141 and 142:

18. High Clutch and Reverse Clutch

- Page 143 and 144:

C: ASSEMBLY (1) Reverse clutch drum

- Page 145 and 146:

10) Apply compressed air intermitte

- Page 147 and 148:

19. Low Clutch Drum and Planetary G

- Page 149 and 150:

9) Install the one-way clutch inner

- Page 151 and 152:

4) Install ST to low clutch drum. S

- Page 153 and 154:

15) Install rear sun gear. NOTE: Pa

- Page 155 and 156:

4) Measurement of backlash (Selecti

- Page 157 and 158:

6) Using ST1 and ST2, install snap

- Page 159 and 160:

23. Transmission Control Module (TC

- Page 161 and 162:

3-3 [C100] COMPONENT PARTS 1. Manua

- Page 163 and 164:

3-3 [W1A0] SERVICE PROCEDURE 1. Man

- Page 165 and 166:

3-3 [W1E0] SERVICE PROCEDURE 1. Man

- Page 167 and 168:

3-3 [W2C0] SERVICE PROCEDURE 2. Aut

- Page 169 and 170:

3-4 [S1A0] SPECIFICATIONS AND SERVI

- Page 171 and 172:

3-4 [S2C1] SPECIFICATIONS AND SERVI

- Page 173 and 174:

3-4 [S2C3] SPECIFICATIONS AND SERVI

- Page 175 and 176:

3-4 [C2A0] COMPONENT PARTS 2. Rear

- Page 177 and 178:

3-4 [C2B2] COMPONENT PARTS 2. Rear

- Page 179 and 180:

3-4 [W1A0] SERVICE PROCEDURE 1. Pro

- Page 181 and 182:

3-4 [W1F0] SERVICE PROCEDURE 1. Pro

- Page 183 and 184:

3-4 [W2A2] SERVICE PROCEDURE 2. Rea

- Page 185 and 186:

3-4 [W2B0] SERVICE PROCEDURE 2. Rea

- Page 187 and 188:

3-4 [W2C0] SERVICE PROCEDURE 2. Rea

- Page 189 and 190:

3-4 [W2C0] SERVICE PROCEDURE 2. Rea

- Page 191 and 192:

3-4 [W2E0] SERVICE PROCEDURE 2. Rea

- Page 193 and 194:

3-4 [W2E0] SERVICE PROCEDURE 2. Rea

- Page 195 and 196:

3-4 [W2E0] SERVICE PROCEDURE 2. Rea

- Page 197 and 198:

3-4 [W2E0] SERVICE PROCEDURE 2. Rea

- Page 199 and 200:

3-4 [W2E0] SERVICE PROCEDURE 2. Rea

- Page 201 and 202:

3-4 [W3A1] SERVICE PROCEDURE 3. Rea

- Page 203 and 204:

3-4 [W3A2] SERVICE PROCEDURE 3. Rea

- Page 205 and 206:

3-4 [W3B0] SERVICE PROCEDURE 3. Rea

- Page 207 and 208:

3-4 [W3C0] SERVICE PROCEDURE 3. Rea

- Page 209 and 210:

3-4 [W3D0] SERVICE PROCEDURE 3. Rea

- Page 211 and 212:

3-4 [W3E0] SERVICE PROCEDURE 3. Rea

- Page 213 and 214:

3-4 [W3E0] SERVICE PROCEDURE 3. Rea

- Page 215 and 216:

3-4 [W3E0] SERVICE PROCEDURE 3. Rea

- Page 217 and 218:

3-4 [W3E0] SERVICE PROCEDURE 3. Rea

- Page 219 and 220:

3-4 [W4A1] SERVICE PROCEDURE 4. Rea

- Page 221 and 222:

3-4 [K100] DIAGNOSTICS 1. Propeller