Draft Business Waste Strategy PDF - london.gov.uk - Greater ...

Draft Business Waste Strategy PDF - london.gov.uk - Greater ...

Draft Business Waste Strategy PDF - london.gov.uk - Greater ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

104 Mayor of London<br />

Making waste work in London The Mayor’s <strong>Draft</strong> <strong>Business</strong> <strong>Waste</strong> Management <strong>Strategy</strong><br />

marketplace by taking delegates through a three-day programme<br />

delivered by successful entrepreneurs and environmentalists.<br />

Source: Enviro Entrepreneur School<br />

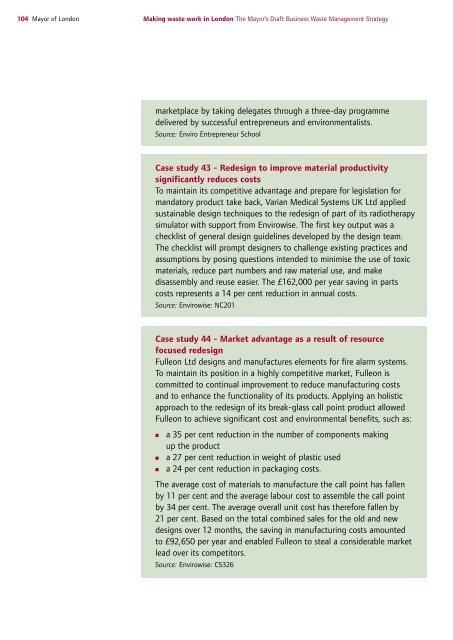

Case study 43 - Redesign to improve material productivity<br />

significantly reduces costs<br />

To maintain its competitive advantage and prepare for legislation for<br />

mandatory product take back, Varian Medical Systems UK Ltd applied<br />

sustainable design techniques to the redesign of part of its radiotherapy<br />

simulator with support from Envirowise. The first key output was a<br />

checklist of general design guidelines developed by the design team.<br />

The checklist will prompt designers to challenge existing practices and<br />

assumptions by posing questions intended to minimise the use of toxic<br />

materials, reduce part numbers and raw material use, and make<br />

disassembly and reuse easier. The £162,000 per year saving in parts<br />

costs represents a 14 per cent reduction in annual costs.<br />

Source: Envirowise: NC201<br />

Case study 44 - Market advantage as a result of resource<br />

focused redesign<br />

Fulleon Ltd designs and manufactures elements for fire alarm systems.<br />

To maintain its position in a highly competitive market, Fulleon is<br />

committed to continual improvement to reduce manufacturing costs<br />

and to enhance the functionality of its products. Applying an holistic<br />

approach to the redesign of its break-glass call point product allowed<br />

Fulleon to achieve significant cost and environmental benefits, such as:<br />

■ a 35 per cent reduction in the number of components making<br />

up the product<br />

■ a 27 per cent reduction in weight of plastic used<br />

■ a 24 per cent reduction in packaging costs.<br />

The average cost of materials to manufacture the call point has fallen<br />

by 11 per cent and the average labour cost to assemble the call point<br />

by 34 per cent. The average overall unit cost has therefore fallen by<br />

21 per cent. Based on the total combined sales for the old and new<br />

designs over 12 months, the saving in manufacturing costs amounted<br />

to £92,650 per year and enabled Fulleon to steal a considerable market<br />

lead over its competitors.<br />

Source: Envirowise: CS326