COST 507 - Repositório Aberto da Universidade do Porto

COST 507 - Repositório Aberto da Universidade do Porto

COST 507 - Repositório Aberto da Universidade do Porto

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

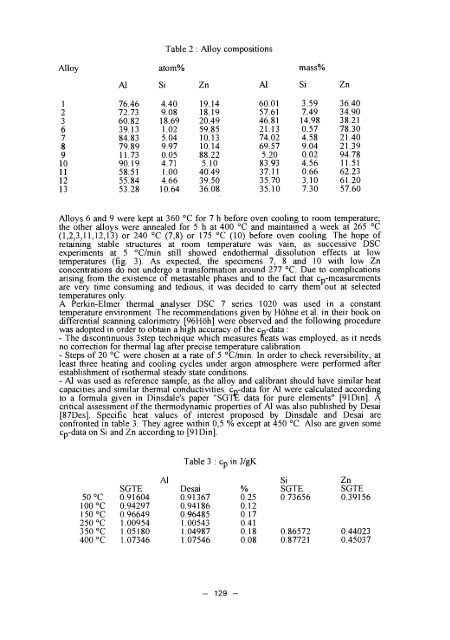

Table 2 : Alloy compositions<br />

Alloy<br />

atom%<br />

mass%<br />

Al<br />

Si<br />

Zn<br />

Λ1<br />

Si<br />

Zn<br />

1<br />

2<br />

3<br />

6<br />

7<br />

S<br />

9<br />

10<br />

11<br />

12<br />

13<br />

76.46<br />

72.73<br />

60.82<br />

39.13<br />

84.83<br />

79.89<br />

11.73<br />

90.19<br />

58.51<br />

55.84<br />

53.28<br />

4.40<br />

9.08<br />

18.69<br />

1.02<br />

5.04<br />

9.97<br />

0.05<br />

4.71<br />

1.00<br />

4.66<br />

10.64<br />

19.14<br />

18.19<br />

20.49<br />

59.85<br />

10.13<br />

10.14<br />

88.22<br />

5.10<br />

40.49<br />

39.50<br />

36.08<br />

60.01<br />

57.61<br />

46.81<br />

21.13<br />

74.02<br />

69.57<br />

5.20<br />

83.93<br />

37.11<br />

35.70<br />

35.10<br />

3.59<br />

7.49<br />

14.98<br />

0.57<br />

4.58<br />

9.04<br />

0.02<br />

4.56<br />

0.66<br />

3.10<br />

7.30<br />

36.40<br />

34.90<br />

38.21<br />

78.30<br />

21.40<br />

21.39<br />

94.78<br />

11.51<br />

62.23<br />

61.20<br />

57.60<br />

Alloys 6 and 9 were kept at 360 °C for 7 h before oven cooling to room temperature;<br />

the other alloys were annealed for 5 h at 400 °C and maintained a week at 265 °C<br />

(1,2,3,11,12,13) or 240 °C (7,8) or 175 °C (10) before oven cooling. The hope of<br />

retaining stable structures at room temperature was vain, as successive DSC<br />

experiments at 5 °C/min still showed en<strong>do</strong>thermal dissolution effects at low<br />

temperatures (fig. 3). As expected, the specimens 7, 8 and 10 with low Zn<br />

concentrations <strong>do</strong> not undergo a transformation around 277 °C. Due to complications<br />

arising from the existence or metastable phases and to the fact that Cpmeasurements<br />

are very time consuming and tedious, it was decided to carry them out at selected<br />

temperatures only.<br />

A PerkinElmer thermal analyser DSC 7 series 1020 was used in a constant<br />

temperature environment. The recommen<strong>da</strong>tions given by Höhne et al. in their book on<br />

differential scanning calorimetry [96Hoh] were observed and the following procedure<br />

was a<strong>do</strong>pted in order to obtain a high accuracy of the Cp<strong>da</strong>ta :<br />

The discontinuous 3step technique which measures heats was employed, as it needs<br />

no correction for thermal lag after precise temperature calibration.<br />

Steps of 20 °C were chosen at a rate of 5 °C/min. In order to check reversibility, at<br />

least three heating and cooling cycles under argon atmosphere were performed after<br />

establishment of isothermal steady state conditions.<br />

AI was used as reference sample, as the alloy and calibrant should have similar heat<br />

capacities and similar thermal conductivities. Cp<strong>da</strong>ta for Al were calculated according<br />

to a formula given in Dins<strong>da</strong>le's paper "SGTK <strong>da</strong>ta for pure elements" [91 Din]. A<br />

critical assessment of the thermodynamic properties of AI was also published by Desai<br />

[87Des]. Specific heat values of interest proposed by Dins<strong>da</strong>le and Desai are<br />

confronted in table 3. They agree within 0,5 % except at 450 °C. Also are given some<br />

Cp<strong>da</strong>ta on Si and Zn according to [91 Din].<br />

Table 3 : Cp in J/gK<br />

50 °C<br />

100 °C<br />

150°C<br />

250 °C<br />

350 °C<br />

400 °C<br />

SGTE<br />

0.91604<br />

0.94297<br />

0.96649<br />

1.00954<br />

1.05180<br />

1.07346<br />

Al<br />

Desai<br />

0.91367<br />

0.94186<br />

0.96485<br />

1.00543<br />

1.04987<br />

1.07546<br />

%<br />

0.25<br />

0.12<br />

0.17<br />

0.41<br />

0.18<br />

0.08<br />

Si<br />

SGTE<br />

0.73656<br />

0.86572<br />

0.87721<br />

Zn<br />

SGTE<br />

0.39156<br />

0.44023<br />

0.45037<br />

129