Vacuum Design Constraints and Considerations - Owens Design

Vacuum Design Constraints and Considerations - Owens Design

Vacuum Design Constraints and Considerations - Owens Design

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

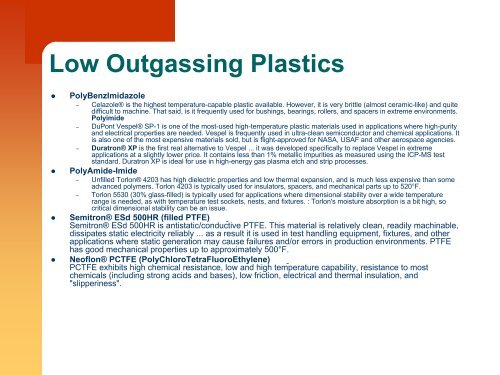

Low Outgassing Plastics<br />

• PolyBenzImidazole<br />

– Celazole® is the highest temperature-capable plastic available. However, it is very brittle (almost ceramic-like) <strong>and</strong> quite<br />

difficult to machine. That said, is it frequently used for bushings, bearings, rollers, <strong>and</strong> spacers in extreme environments.<br />

Polyimide<br />

– DuPont Vespel® SP-1 is one of the most-used high-temperature plastic materials used in applications where high-purity<br />

<strong>and</strong> electrical properties are needed. Vespel is frequently used in ultra-clean semiconductor <strong>and</strong> chemical applications. It<br />

is also one of the most expensive materials sold, but is flight-approved for NASA, USAF <strong>and</strong> other aerospace agencies.<br />

– Duratron® XP is the first real alternative to Vespel ... it was developed specifically to replace Vespel in extreme<br />

applications at a slightly lower price. It contains less than 1% metallic impurities as measured using the ICP-MS test<br />

st<strong>and</strong>ard. Duratron XP is ideal for use in high-energy gas plasma etch <strong>and</strong> strip processes.<br />

• PolyAmide-Imide<br />

– Unfilled Torlon® 4203 has high dielectric properties <strong>and</strong> low thermal expansion, <strong>and</strong> is much less expensive than some<br />

advanced polymers. Torlon 4203 is typically used for insulators, spacers, <strong>and</strong> mechanical parts up to 520°F.<br />

– Torlon 5530 (30% glass-filled) is typically used for applications where dimensional stability over a wide temperature<br />

range is needed, as with temperature test sockets, nests, <strong>and</strong> fixtures. : Torlon's moisture absorption is a bit high, so<br />

critical dimensional stability can be an issue.<br />

• Semitron® ESd 500HR (filled PTFE)<br />

Semitron® ESd 500HR is antistatic/conductive PTFE. This material is relatively clean, readily machinable,<br />

dissipates static electricity reliably ... as a result it is used in test h<strong>and</strong>ling equipment, fixtures, <strong>and</strong> other<br />

applications where static generation may cause failures <strong>and</strong>/or errors in production environments. PTFE<br />

has good mechanical properties up to approximately 500°F.<br />

• Neoflon® PCTFE (PolyChloroTetraFluoroEthylene)<br />

PCTFE exhibits high chemical resistance, low <strong>and</strong> high temperature capability, resistance to most<br />

chemicals (including strong acids <strong>and</strong> bases), low friction, electrical <strong>and</strong> thermal insulation, <strong>and</strong><br />

"slipperiness".