Vacuum Design Constraints and Considerations - Owens Design

Vacuum Design Constraints and Considerations - Owens Design

Vacuum Design Constraints and Considerations - Owens Design

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

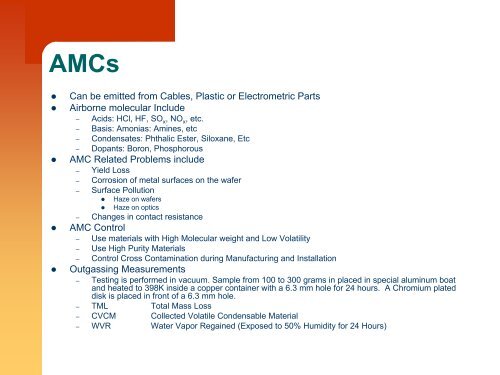

AMCs<br />

• Can be emitted from Cables, Plastic or Electrometric Parts<br />

• Airborne molecular Include<br />

– Acids: HCl, HF, SO x , NO x , etc.<br />

– Basis: Amonias: Amines, etc<br />

– Condensates: Phthalic Ester, Siloxane, Etc<br />

– Dopants: Boron, Phosphorous<br />

• AMC Related Problems include<br />

– Yield Loss<br />

– Corrosion of metal surfaces on the wafer<br />

– Surface Pollution<br />

• Haze on wafers<br />

• Haze on optics<br />

– Changes in contact resistance<br />

• AMC Control<br />

– Use materials with High Molecular weight <strong>and</strong> Low Volatility<br />

– Use High Purity Materials<br />

– Control Cross Contamination during Manufacturing <strong>and</strong> Installation<br />

• Outgassing Measurements<br />

– Testing is performed in vacuum. Sample from 100 to 300 grams in placed in special aluminum boat<br />

<strong>and</strong> heated to 398K inside a copper container with a 6.3 mm hole for 24 hours. A Chromium plated<br />

disk is placed in front of a 6.3 mm hole.<br />

– TML Total Mass Loss<br />

– CVCM Collected Volatile Condensable Material<br />

– WVR Water Vapor Regained (Exposed to 50% Humidity for 24 Hours)