Kent Design - Technical Appendix - Kent County Council

Kent Design - Technical Appendix - Kent County Council

Kent Design - Technical Appendix - Kent County Council

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A separate chemical contamination risk assessment should also be<br />

undertaken for the whole development.<br />

3.2.1.3 SUB-SOIL DRAINAGE<br />

Every endeavour should be made to prevent the water table from<br />

rising to within 600mm of formation level. Methods of preventing this<br />

should be discussed with the Engineer at time of designing the works<br />

3.2.1.4 EARTHWORKS<br />

All turf and topsoil shall be removed from the formation of the new road.<br />

It shall be stored carefully on site up to a maximum of 2m in height to<br />

prevent deterioration and contamination with sub-soil etc and shall<br />

wherever possible be reused within the site. Only with the agreement of<br />

the Engineer may surplus material be removed from the site.<br />

If in-situ stabilisation of the existing soil is to be used instead of<br />

imported granular capping layer there will be considerably less<br />

material to be removed<br />

Other organic materials within the site of the new road shall be<br />

identified, removed and their disposal agreed with the Engineer.<br />

Wherever possible they shall be reused within the site by the<br />

construction of appropriate mounds/landscaping features.<br />

The area of the carriageway shall be excavated or filled to produce<br />

the formation level.<br />

Where local areas are uncovered which are softer than the general<br />

sub-grade they shall be excavated out to a depth appropriate for the<br />

soft area and backfilled with material similar to the surrounding<br />

formation. Where soft areas exceed 25% of the total area of<br />

carriageway in which they occur, the whole area shall be reduced in<br />

level and suitable material substituted. All other unsuitable material,<br />

other than organic material, shall be considered for treatment to<br />

make it suitable for use in the carriageway works, footways, verges<br />

or other parts of the site. Only with the agreement of the Engineer<br />

may surplus material be removed from the site.<br />

Fill material shall comply with ‘suitable material’ as defined in the<br />

Specification.<br />

3.2.1.5 SERVICE DUCTS AND PIPEWORK<br />

Ducts and pipework shall wherever possible not be located in the<br />

carriageway. Where service crossings make this unavoidable, they<br />

shall be installed prior to carriageway construction and protected<br />

from damage by subsequent construction.<br />

3.3 CARRIAGEWAY- SUB-BASE AND CAPPING LAYER<br />

3.3.1.1 SUB -BASE AND CAPPING LAYER DESIGN THICKNESS<br />

For District Distributor roads and Industrial Access Roads the thickness<br />

of sub-base shall be determined in accordance with the <strong>Design</strong><br />

Manual for Road and Bridge Works Volume 7 Section 2 Chapter<br />

3 HD25 for the estimated volume of traffic as agreed with the Engineer.<br />

Only ‘Flexible pavements’ are permitted. Where the capping layer<br />

option is preferred, the reasons for not improving the CBR of the subgrade<br />

by stabilisation shall be discussed with the Engineer<br />

For Local Distributor, Major Access Roads, Minor Access Roads, Minor<br />

Access Ways and Homezones the design process shall be as follows:<br />

Carry out four thickness designs using the equilibrium CBR of the<br />

formation for the long term condition and the anticipated CBR at the<br />

time of construction for the short term condition. The latter will<br />

need to be rechecked at time of construction.<br />

Select the thickness for sub-base alone and for Capping layer options<br />

which are the more conservative.<br />

Determine on economic practicality or sustainability grounds<br />

whether to use the sub-base option or capping layer option.<br />

It is not intended that the sub-base be used as a access for the construction<br />

of buildings. Access should be provided separately or by using the surface<br />

of the basecourse prior to laying the blacktop or block surfacing.<br />

The thickness design below is based on the works being carried out by a<br />

company quality assured for this activity. Records of the CBR at the time<br />

of construction, the thickness of the laid materials and the compaction<br />

plant used shall be made available to the Engineer. Where the works are<br />

not carried out by a company quality assured for this activity, the thickness<br />

of sub-base and capping shall each be increased by 20%.<br />

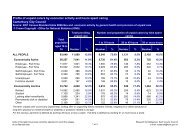

For the purposes of this design guide the following traffic figures in<br />

table 10 have been assumed. For the purpose of structural pavement<br />

design the roads should be designated as shown in the table<br />

irrespective of descriptions used for other purposes.<br />

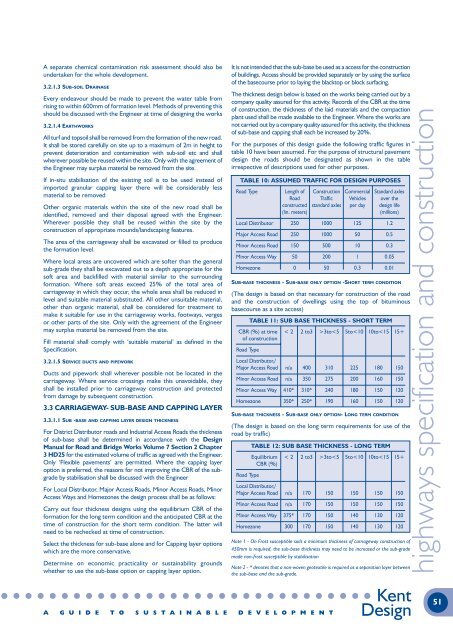

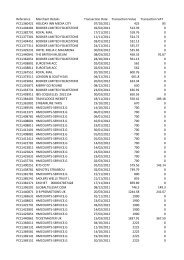

TABLE 10: ASSUMED TRAFFIC FOR DESIGN PURPOSES<br />

Road Type Length of Construction Commercial Standard axles<br />

Road Traffic Vehicles over the<br />

constructed standard axles per day design life<br />

(lin. meters)<br />

(millions)<br />

Local Distributor 250 1000 125 1.2<br />

Major Access Road 250 1000 50 0.5<br />

Minor Access Road 150 500 10 0.3<br />

Minor Access Way 50 200 1 0.05<br />

Homezone 0 50 0.3 0.01<br />

SUB-BASE THICKNESS - SUB-BASE ONLY OPTION -SHORT TERM CONDITION<br />

(The design is based on that necessary for construction of the road<br />

and the construction of dwellings using the top of bituminous<br />

basecourse as a site access)<br />

TABLE 11: SUB BASE THICKNESS - SHORT TERM<br />

CBR (%) at time < 2 2 to3 >3to