- Page 1 and 2:

FRICTION STIR WELDING OF SPHERES, C

- Page 3 and 4:

TABLE OF CONTENTS TABLE OF FIGURES

- Page 5 and 6:

Appendix ..........................

- Page 7 and 8:

Figure 16: Left(FE streamline), Mid

- Page 9 and 10:

Figure 51: A thermal camera image t

- Page 11 and 12:

for a similar conventional weld (3/

- Page 13 and 14:

Figure 102: Tapered retraction proc

- Page 15 and 16:

setting are indicated. Note that st

- Page 17 and 18:

Unsupported welds of this kind with

- Page 19 and 20:

Figure 157: A thermal camera image

- Page 21 and 22:

ottom sample is a tungsten inert ga

- Page 23 and 24:

N - newton (force unit) n - visco-p

- Page 25 and 26:

INTRODUCTION Friction Stir Welding,

- Page 27 and 28:

educed conduction lengths. In small

- Page 29 and 30:

CHAPTER I LITERATURE REVIEW: COMPUT

- Page 31 and 32:

frictional condition at the interfa

- Page 33 and 34:

contact. The contact area can inclu

- Page 35 and 36:

For horizontal sections, a heat inp

- Page 37 and 38:

(1.11) where r p is the probe (pin)

- Page 39 and 40:

This efficiency term, η pd , is kn

- Page 41 and 42:

The heat input on the tool surface

- Page 43 and 44:

The added complication of these met

- Page 45 and 46:

Figure 5: Lateral cross sections of

- Page 47 and 48:

Flow stress in aluminum alloys is d

- Page 49 and 50:

Figure 8: Three flow fields a) rota

- Page 51 and 52:

and post-weld cool-down. This model

- Page 53 and 54:

Williams et al. [60] use a 2D-axisy

- Page 55 and 56:

Figure 16: Left(FE streamline), Mid

- Page 57 and 58:

Figure 18: Temperature contour over

- Page 59 and 60:

Figure 22: Temperature distribution

- Page 61 and 62:

Figure 24: Lateral velocity contour

- Page 63 and 64:

Figure 26: Experimental(white) vers

- Page 65 and 66:

Figure 28: Top view schematic of tu

- Page 67 and 68:

[5] Taylor RE, Groot H, Goerz T, Fe

- Page 69 and 70:

[41] Heinz B., Skrotzki B., Eggler

- Page 71 and 72:

CHAPTER II COMPUTATIONAL ANALYSIS O

- Page 73 and 74:

Figure 30: Blind t-joint setup with

- Page 75 and 76: Figure 33: Process forces and later

- Page 77 and 78: Figure 35: Experimental Welds, Axia

- Page 79 and 80: Figure 37: FEA boundary conditions

- Page 81 and 82: A 4500 N axial force is applied eve

- Page 83 and 84: axial force with lateral offset dur

- Page 85 and 86: Figure 42: Contour plot of von Mise

- Page 87 and 88: Figure 44: Deformation contour for

- Page 89 and 90: Figure 46: Quarter-plate model for

- Page 91 and 92: Figure 49: Contour plot of deflecti

- Page 93 and 94: where P is the weld power (W), Q is

- Page 95 and 96: Figure 52: Fluent CFD model zones.

- Page 97 and 98: Figure 55: Thermal contour of weld

- Page 99 and 100: Figure 59: Thermal contour of weld

- Page 101 and 102: Figure 61: Velocity vectors for 0.0

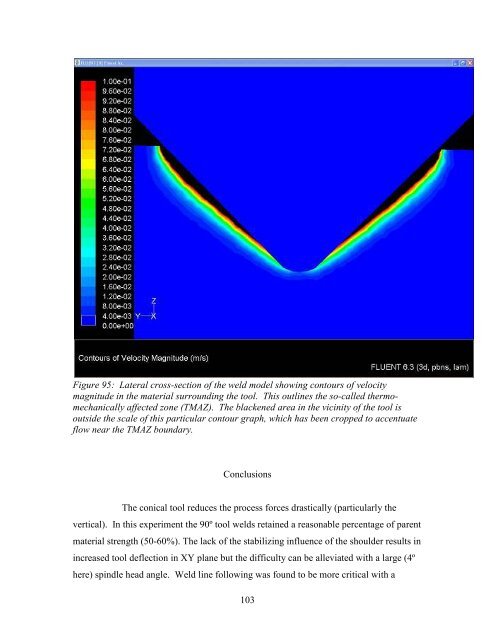

- Page 103 and 104: Figure 65: Contour of velocity magn

- Page 105 and 106: CHAPTER III THE APPLICATION OF SHOU

- Page 107 and 108: Figure 66: A shoulder-less, conical

- Page 109 and 110: Figure 68: Typical axial(Z-axis) fo

- Page 111 and 112: Figure 71: 90° conical tool macros

- Page 113 and 114: Figure 75: Run 3, 80° conical tool

- Page 115 and 116: Figure 79: (90º tool) Ultimate ten

- Page 117 and 118: Figure 83: (90º tool) Lateral forc

- Page 119 and 120: Figure 87: (80º tool) Lateral forc

- Page 121 and 122: The Eulerian, finite volume, CFD so

- Page 123 and 124: Figure 92 shows the increasing elem

- Page 125: Figure 91: CFD model geometry consi

- Page 129 and 130: Figure 96: Attempts a probe tapered

- Page 131 and 132: CHAPTER IV THE FRICTION STIR WELDIN

- Page 133 and 134: applications for its high strength

- Page 135 and 136: Figure 97: Experimental weld sample

- Page 137 and 138: Figure 99: Split protrusion type de

- Page 139 and 140: with a cupped recess. It is however

- Page 141 and 142: of tapered retraction (i.e. move th

- Page 143 and 144: The adjustments in vertical positio

- Page 145 and 146: manners the assigned depth was main

- Page 147 and 148: Figure 108: Lateral macrosections f

- Page 149 and 150: Figure 110: (Supported, cupped tool

- Page 151 and 152: Figure 112: (Supported, cupped tool

- Page 153 and 154: Figure 114: (Supported, cupped tool

- Page 155 and 156: apparent strength of 26% parent whi

- Page 157 and 158: with a 100º conical tool (0.025”

- Page 159 and 160: Figure 119: Macrosection view of an

- Page 161 and 162: and tooling. Torque is highly depen

- Page 163 and 164: locally in proportion to the local

- Page 165 and 166: Figure 126: (threaded tool) Contour

- Page 167 and 168: Figure 128: (conical tool) Geometry

- Page 169 and 170: Figure 131: (threaded tool) Lateral

- Page 171 and 172: The results presented here show tha

- Page 173 and 174: Figure 136:(from left: Tapered retr

- Page 175 and 176: [8] Metallurgical analysis of ablat

- Page 177 and 178:

CHAPTER V FRICTION STIR WELDING OF

- Page 179 and 180:

Collaboration between Advanced Meta

- Page 181 and 182:

eccentricity, the method of interio

- Page 183 and 184:

gas tungsten arc welding of small d

- Page 185 and 186:

Full penetration welds of 4.2” (1

- Page 187 and 188:

Figure 143: The curvature of the pi

- Page 189 and 190:

Figure 144: Experimental axial forc

- Page 191 and 192:

Together, a fine wall thickness tol

- Page 193 and 194:

Figure 147: Axial force history for

- Page 195 and 196:

The weld macrosections show complet

- Page 197 and 198:

Figure 154: Macrosections of welds

- Page 199 and 200:

Figure 157: A thermal camera image

- Page 201 and 202:

Figure 159: Average tool shank temp

- Page 203 and 204:

471,146 faces. The meshes are fine

- Page 205 and 206:

Figure 162: A closeup view of mesh

- Page 207 and 208:

4 2 3 4 5 16 " 1.745 2 0.24

- Page 209 and 210:

applied heat locally in proportion

- Page 211 and 212:

Figure 164: Modeled temperature con

- Page 213 and 214:

Figure 167: Modeled temperature con

- Page 215 and 216:

Figure 169: Modeled temperature con

- Page 217 and 218:

Figure 172: Model pathlines for the

- Page 219 and 220:

Figure 174: Model pathlines for the

- Page 221 and 222:

later speed setting, the tool welds

- Page 223 and 224:

Figure 178: Zoom view of a macro ta

- Page 225 and 226:

Figure 180: The superficial appeara

- Page 227 and 228:

Figure 182: The rotary welding appa

- Page 229 and 230:

Figure 185: A diagram illustrating

- Page 231 and 232:

CONCLUSION AND FUTURE WORK Conclusi

- Page 233 and 234:

new FSW process environment is reso